V-shaped conveying inner chamfering equipment and using method

A chamfering and equipment technology, applied in the field of spring processing, can solve the problems of poor economy, large space occupied by equipment, and adverse effects on product processing quality, so as to achieve the effect of ensuring the qualified rate and reducing the occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

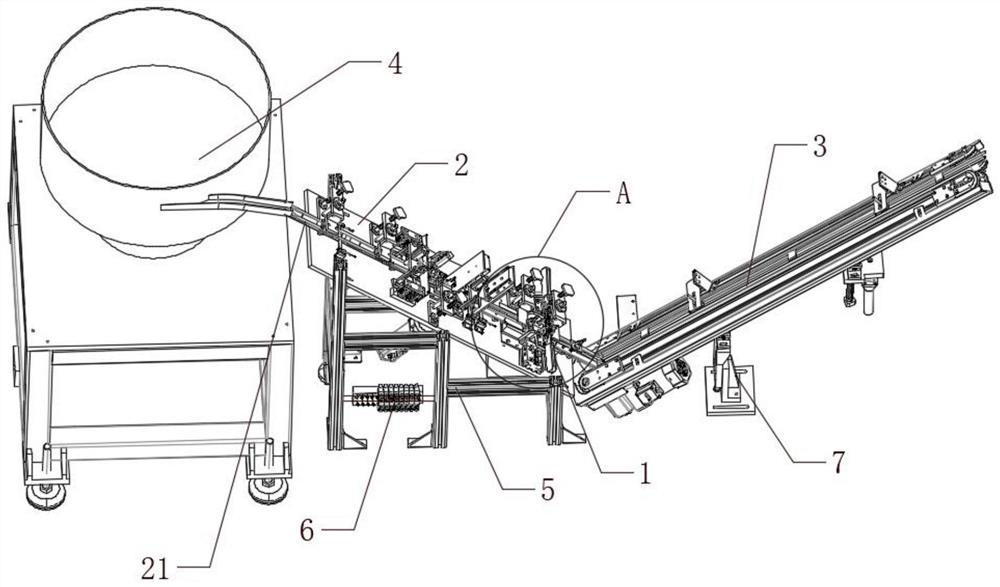

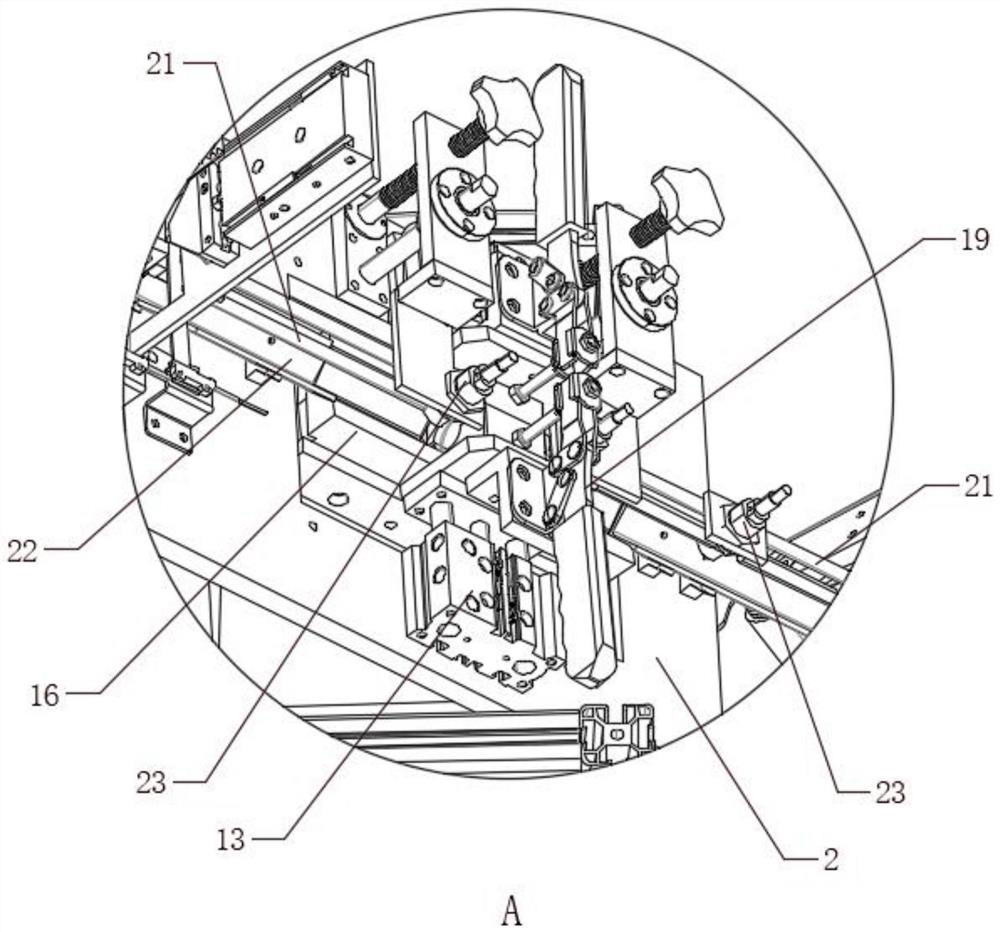

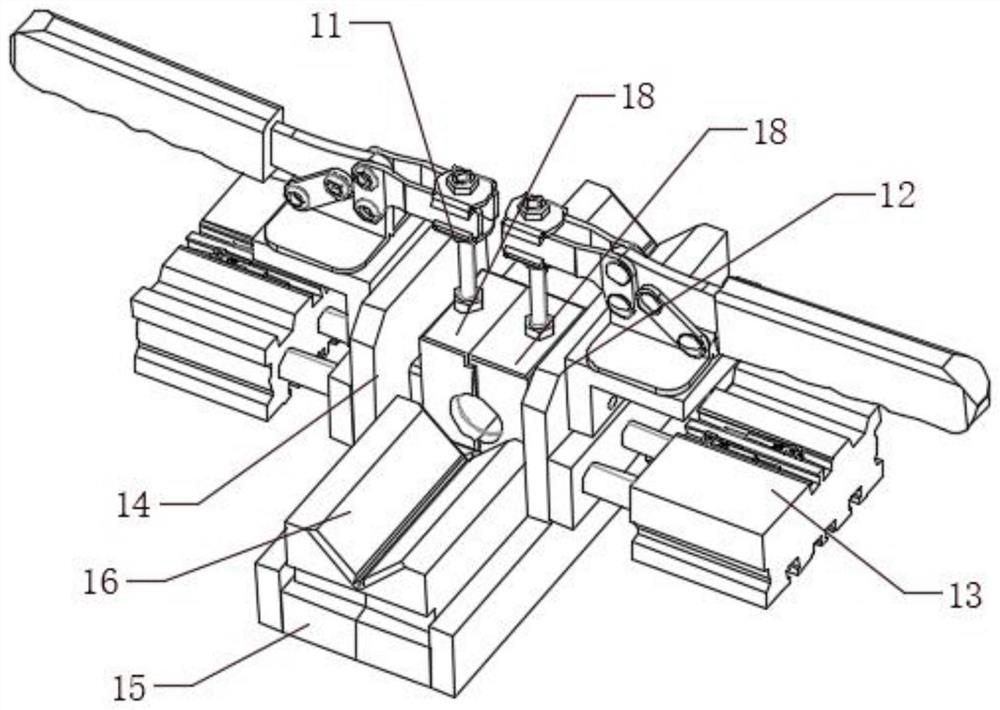

[0049] Such as Figure 1-6 As shown, the V-shaped conveying inner chamfering equipment of the present invention includes an outer diameter detection and discharge assembly 1, a downhill conveying line 2, a climbing conveying line 3, a feeding vibrating plate 4, an outer diameter detection and discharge assembly 1, a downhill The conveyor line 2, the climbing conveyor line 3, and the feeding vibrating plate 4 are all electrically connected to the solenoid valve 6, the tail of the downhill conveyor line 2 is overlapped with the head of the climb conveyor line 3, and the downhill conveyor line 2 is connected to the climber The slope conveying line 3 forms an included angle, the downhill conveying line 2 is connected with the upper part of the downhill support 5, the solenoid valve 6 is connected with the downhill support 5, the bottom of the climbing conveying line 3 is connected with the uphill adjustable support 7, and the downhill A guide assembly 21 is provided on the conveyi...

Embodiment 2

[0063] This embodiment is a further improvement of the previous embodiment, such as Figure 1-6 As shown, the V-shaped conveying inner chamfering equipment of the present invention includes an outer diameter detection and discharge assembly 1, a downhill conveying line 2, a climbing conveying line 3, a feeding vibrating plate 4, an outer diameter detection and discharge assembly 1, a downhill The conveyor line 2, the climbing conveyor line 3, and the feeding vibrating plate 4 are all electrically connected to the solenoid valve 6, the tail of the downhill conveyor line 2 is overlapped with the head of the climb conveyor line 3, and the downhill conveyor line 2 is connected to the climber The slope conveying line 3 forms an included angle, the downhill conveying line 2 is connected with the upper part of the downhill support 5, the solenoid valve 6 is connected with the downhill support 5, the bottom of the climbing conveying line 3 is connected with the uphill adjustable suppor...

Embodiment 3

[0079] This embodiment is a further improvement of the previous embodiment, such as Figure 1-6 As shown, the V-shaped conveying inner chamfering equipment of the present invention includes an outer diameter detection and discharge assembly 1, a downhill conveying line 2, a climbing conveying line 3, a feeding vibrating plate 4, an outer diameter detection and discharge assembly 1, a downhill The conveyor line 2, the climbing conveyor line 3, and the feeding vibrating plate 4 are all electrically connected to the solenoid valve 6, the tail of the downhill conveyor line 2 is overlapped with the head of the climb conveyor line 3, and the downhill conveyor line 2 is connected to the climber The slope conveying line 3 forms an included angle, the downhill conveying line 2 is connected with the upper part of the downhill support 5, the solenoid valve 6 is connected with the downhill support 5, the bottom of the climbing conveying line 3 is connected with the uphill adjustable suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com