Rotating disc type freight platform trailer

A flatbed trailer and turntable technology, which is applied in the direction of freight vehicles, motor vehicles, transport objects, etc., can solve the problems of poor shock absorption effect, cargo hurting people, cargo damage, etc., so as to improve the carrying capacity and reduce vibration Impact, prevent slipping and falling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

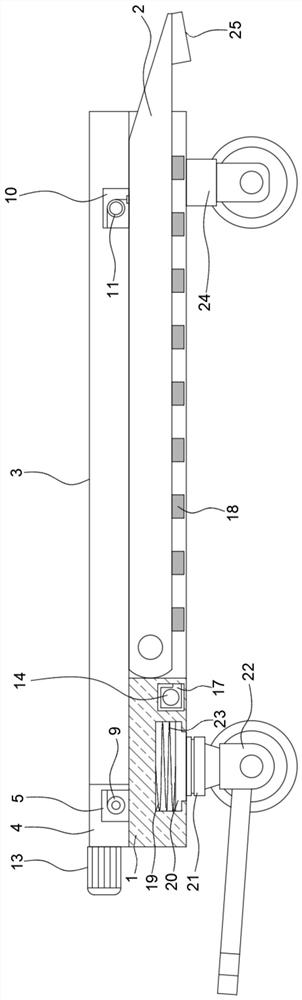

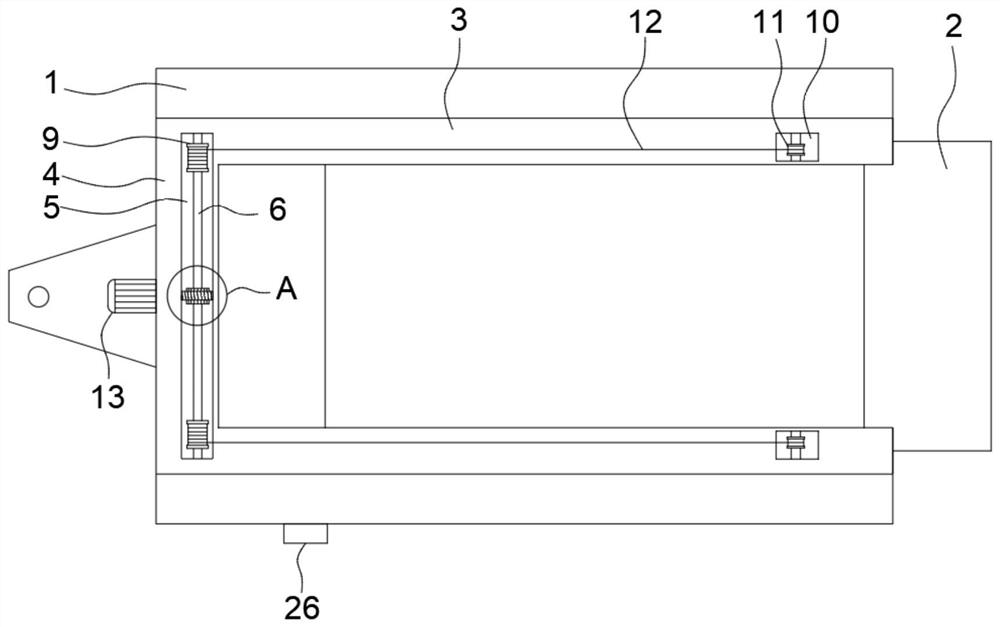

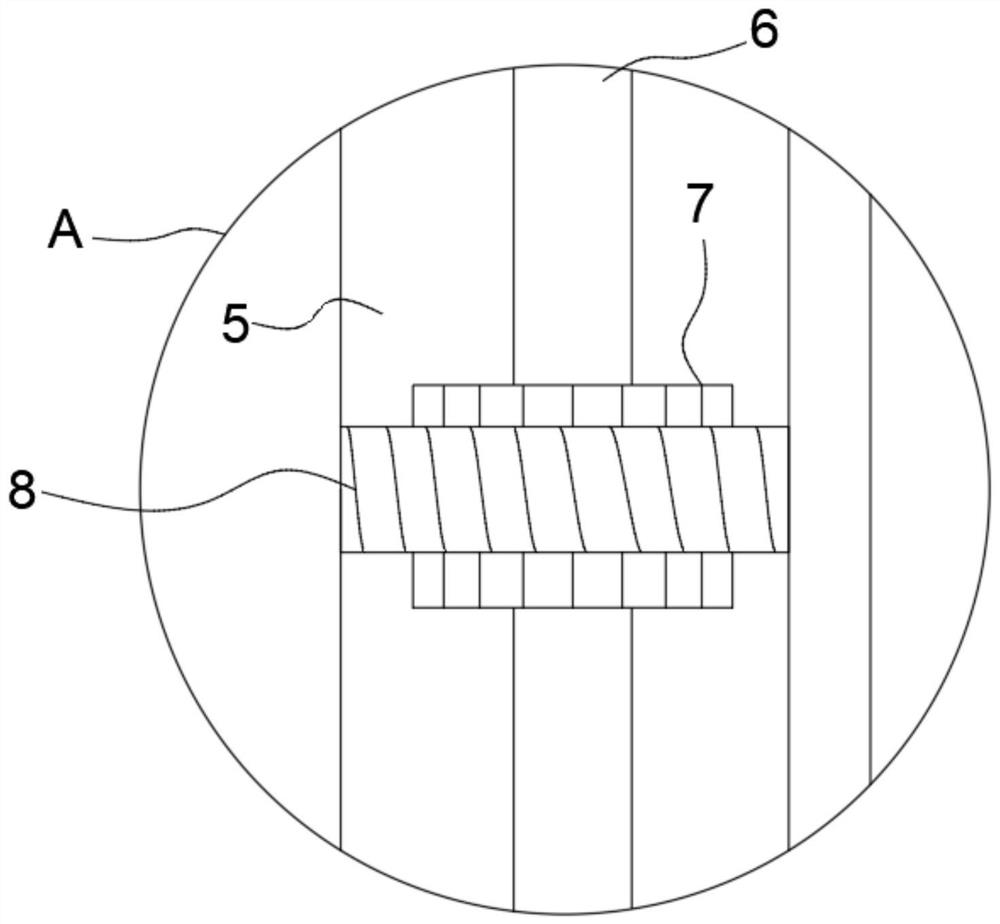

[0026] refer to Figure 1-6 , a turntable type cargo flatbed trailer, comprising a U-shaped vehicle frame 1 when viewed from above, a cargo plate 2 is arranged inside the vehicle frame 1, and the cargo plate 2 is rotationally connected with the front and rear inner walls on the left side of the vehicle frame 1, and the vehicle The upper end of the frame 1 is fixedly connected with a transverse baffle 3 at the front and rear positions of the cargo plate 2, and the ends of the two transverse baffles 3 that want to be close to both extend to the top of the cargo plate 2, which prevents the cargo from being damaged when the cargo is unloaded. It is slippery and can limit the rotation range of the cargo board 2. The upper end of the vehicle frame 1 is fixedly connected with a longitudinal baffle 4 on the left side of the cargo board 2. The left ends of the two transverse baffles 3 are fixedly connected to the right side of the longitudinal baffle 4. , and it is a U-shaped structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com