Dynamic bottle blocking device in bottle conveying mechanism in box filling machine

A bottle conveying and cartoning machine technology, which is applied in the directions of packaging bottles, packaging, transportation and packaging, can solve the problems that robots are difficult to grasp accurately, the amount of bottle extrusion deformation is large, and the packaging efficiency is reduced, and the efficiency is improved. The effect of reducing extrusion deformation and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

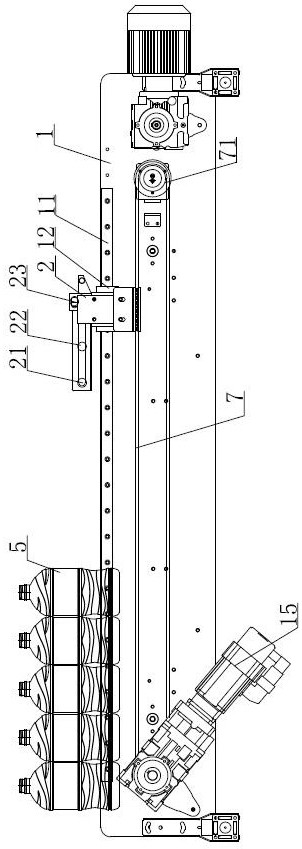

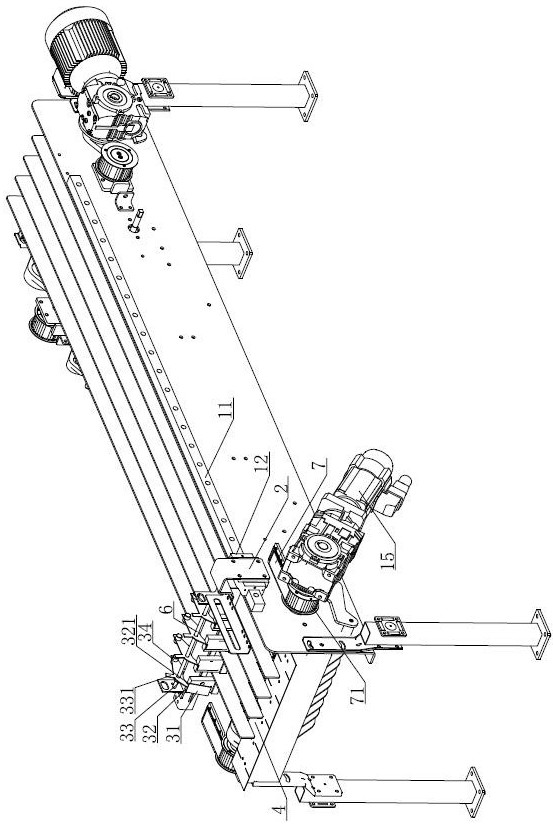

[0015] Such as figure 1 , figure 2 As shown, the dynamic bottle stop device in the bottle conveying mechanism of the case packer includes: a bottle stop bracket 2 arranged on the frame 1, a number of bottle stop components 3 are arranged on the bottle stop bracket 2, and each bottle stop component 3 Correspondingly blocked in a conveying channel 4 . The bottle stop bracket 2 is slidingly connected with the frame 1, and the frame 1 is provided with a drive mechanism, and the bottle stop bracket 2 can slide back and forth on the frame 1 under the drive of the drive mechanism, thereby driving each bottle stop The assembly 3 moves back and forth in the corresponding conveying channel 4 . A first position sensor 21 , a second position sensor 22 and a third position sensor 23 for detecting bottles are arranged at intervals on the bottl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com