Air bubble film with good mechanical properties

A technology of bubble film and performance, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of easy falling off, poor bonding force, low strength of polyethylene film, etc. Improve the effect, improve the binding force, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

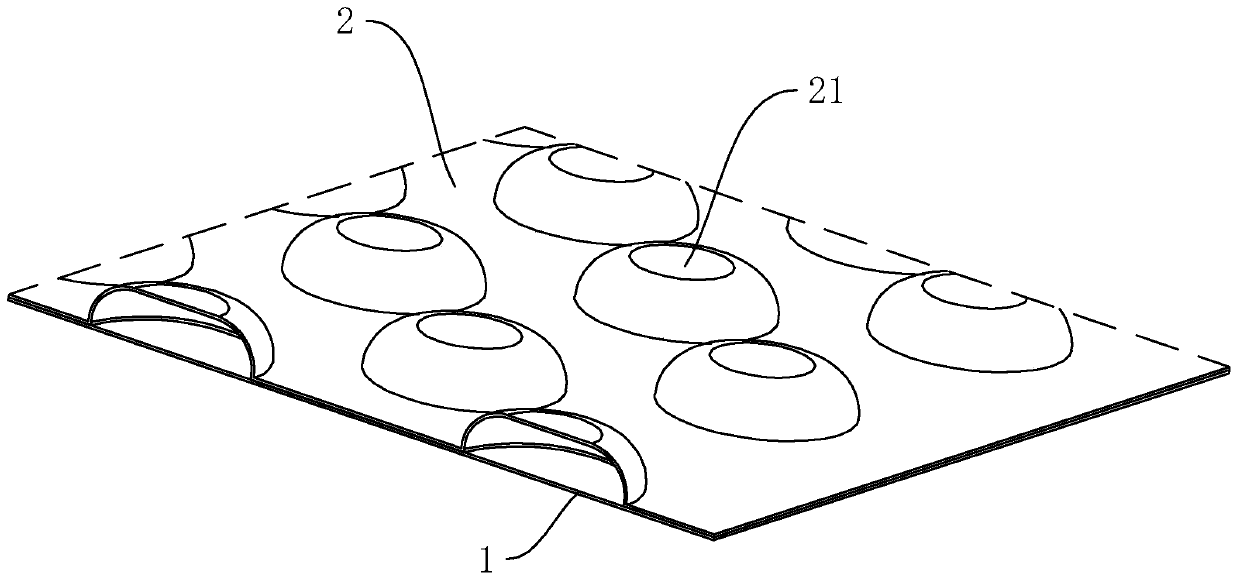

[0050] as attached figure 1 As shown, a high-strength air bubble film includes a base film 1 and a blister film 2 that are attached and fixed. The plastic-absorbing film 2 is distributed with a plurality of blister-forming cylindrical bubbles 21. The shape and distribution of the bubbles 21 under actual production can be determined according to the actual situation. It is not the invention point of the present invention, so no further elaboration will be made here. .

[0051] The bottom film 1 and the blister film 2 are made of modified PE. Modified PE contains the following raw materials in parts by mass:

[0052] LDPE 23-28 parts,

[0053] LLDPE 47-55 parts,

[0054] HDPE 22-26 parts,

[0055] 1-3 parts of opening agent,

[0056] 3-6 parts of sorbic acid,

[0057] 4-5 parts of flame retardant,

[0058] 6-7 parts of stripping liquid.

[0059] LDPE is low-density polyethylene, selected from China Shipping Shell's 242OK product and Saudi Arabia's SABIC brand LD160AT pr...

Embodiment 2

[0085] A high-strength air bubble film, based on Example 1A, the difference is that the stripping liquid is water, the parameter of raw material consumption is the same as that of Example 1A, and the air bubble film is produced according to the production process of the air bubble film in Example 1.

Embodiment 3

[0087] A high-strength air bubble film, based on the basis of Example 1A, the difference is that the amount of stripping liquid is zero, and the parameters of the amount of other raw materials are the same as in Example 1A, and the air bubble film is produced according to the production process of the air bubble film in Example 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com