Liftable multi-layer shuttle vehicle

A shuttle car and lift table technology, applied in the field of automated logistics equipment, can solve problems such as blockage, increased operation time, idle shuttle car, etc., to reduce investment, ensure normal walking, and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

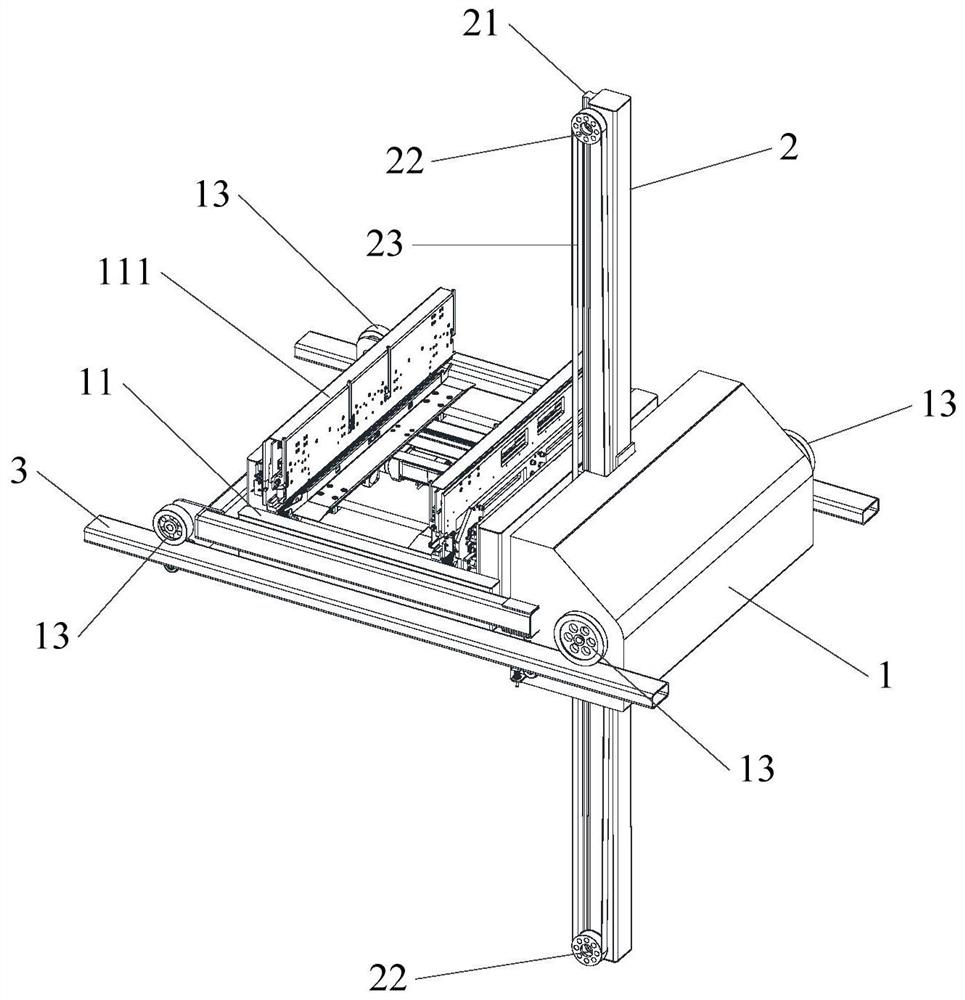

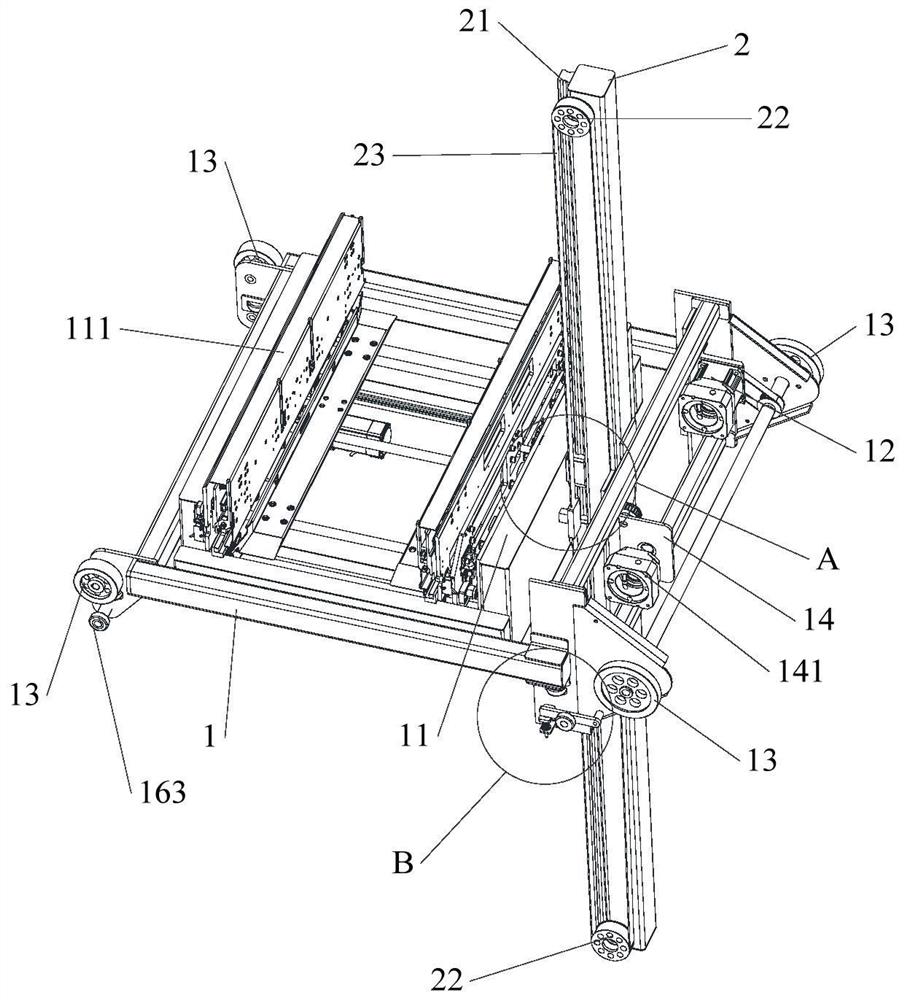

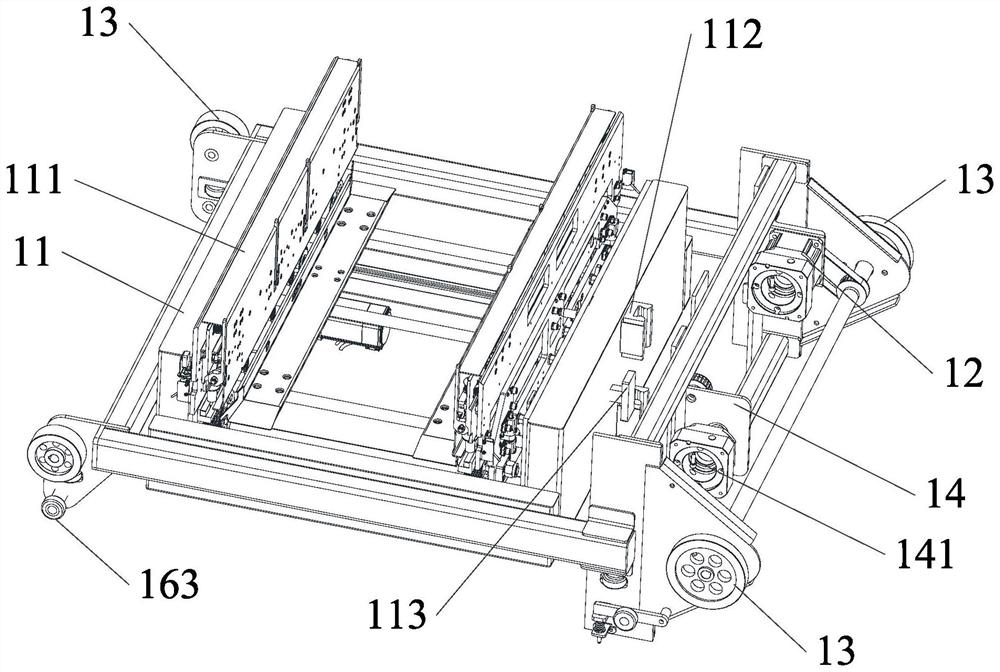

[0032] Such as Figure 1-6 As shown, the present application provides a liftable multi-storey shuttle car, which includes: a car body 1, a running mechanism, a lifting platform 11 arranged on the car body 1, and a cargo fork 111 arranged on the lifting platform 11 1. A column 2 vertically passing through the car body 1, and the traveling mechanism is used to allow the shuttle car to move on the shuttle car track 3. One side of the column 2 is fixedly connected with the car body 1, and a slide rail 21 is provided on the opposite side, and a slide block 112 is provided at a position corresponding to the slide rail 21 on the lifting table 11, and the slide block 112 slides with the slide rail 21 The connection can realize the sliding up and down of the slider. The car body 1 is provided with a lifting motor 141, and the lifting motor 141 is used to drive the vertical movement of the slider 112 on the slide rail 21 of the column 2, thereby driving the lifting table 11 to lift, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com