High-strength double-wave pipeline and preparation method thereof

A high-strength, pipeline technology, applied in pipeline protection, pipeline anti-corrosion/rust protection, pipes, etc., can solve the problems of unsatisfactory ring stiffness and corrosion resistance, easy damage, etc., and achieve high ring stiffness and strong corrosion resistance , good bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

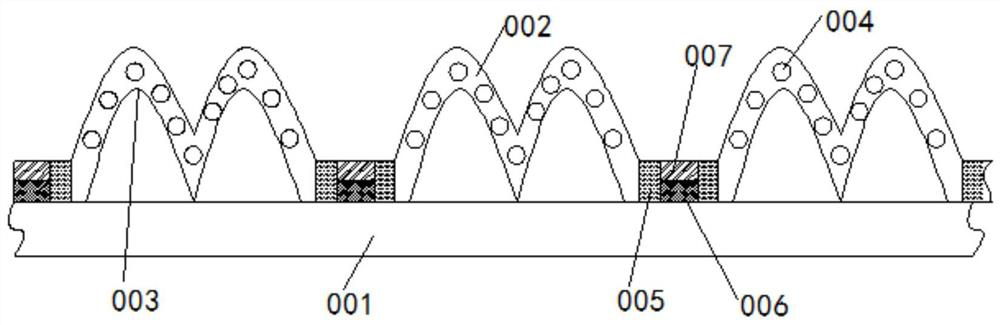

[0028] See figure 1 , this embodiment provides a high-strength double-wave pipeline, including inner polyethylene 001, outer polyethylene 002, perforated steel belt 003, adhesive resin 004, anti-corrosion layer 005, reinforcing belt 006 and heat shrinkable belt 007, The perforated steel belt 003 is set above the inner layer of polyethylene 001. The cross section of the perforated steel belt 003 has M-shaped double wave peaks. The outer layer of polyethylene 002 is placed above the perforated steel belt 003. The interior of polyethylene 002 is provided with adhesive resin 004, and there is a gap between each double-wave crest, and an anti-corrosion layer 005, a reinforcing tape 006 and a heat-shrinkable tape 007 are arranged between the gaps, and the anti-corrosion layer 005 is close to the outer poly Vinyl 002 is set, the reinforcing belt 006 and the heat-shrinkable belt 007 are set outside the anticorrosion layer 005, and the heat-shrinkable belt 007 is set above the reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com