System for monitoring bearings

A technology for monitoring systems and bearings, applied in the direction of bearings, ball bearings, roller bearings, etc., can solve the problems of complex, expensive technology, and the inability to add sensor systems, etc., to achieve the effect of preventing damage and moisture, and avoiding weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

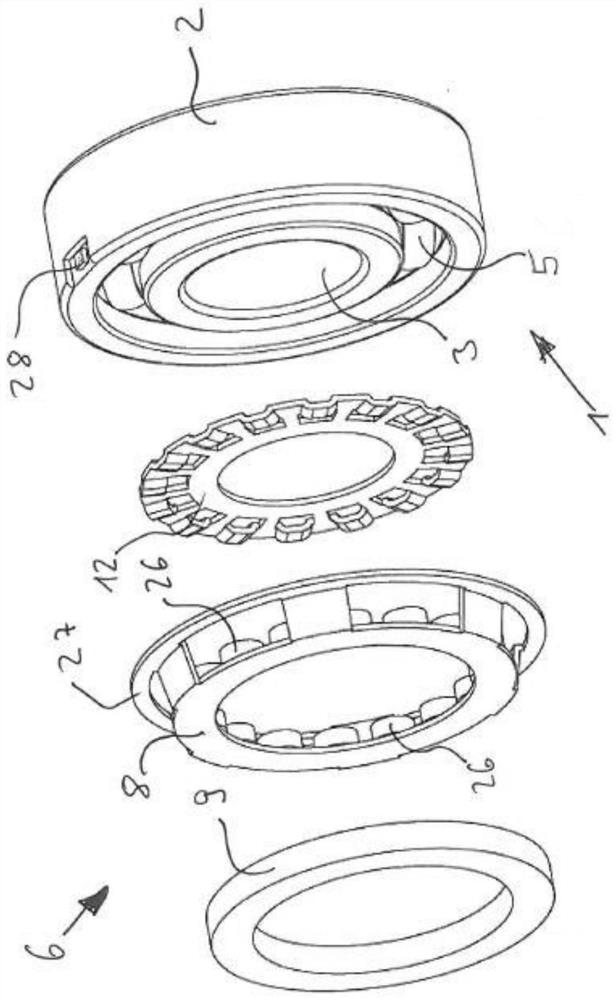

[0041] In the drawings, the same or similar parts are marked with the same reference numerals. Unless otherwise stated, directions refer to the axial and radial directions of the bearings shown, or to the directions in the plane of the drawing. To the extent technically feasible and possible, individual features of different designs may be added to or interchanged with features of other designs. These variations are hereby expressly included in the present invention, even if they are not described in detail again.

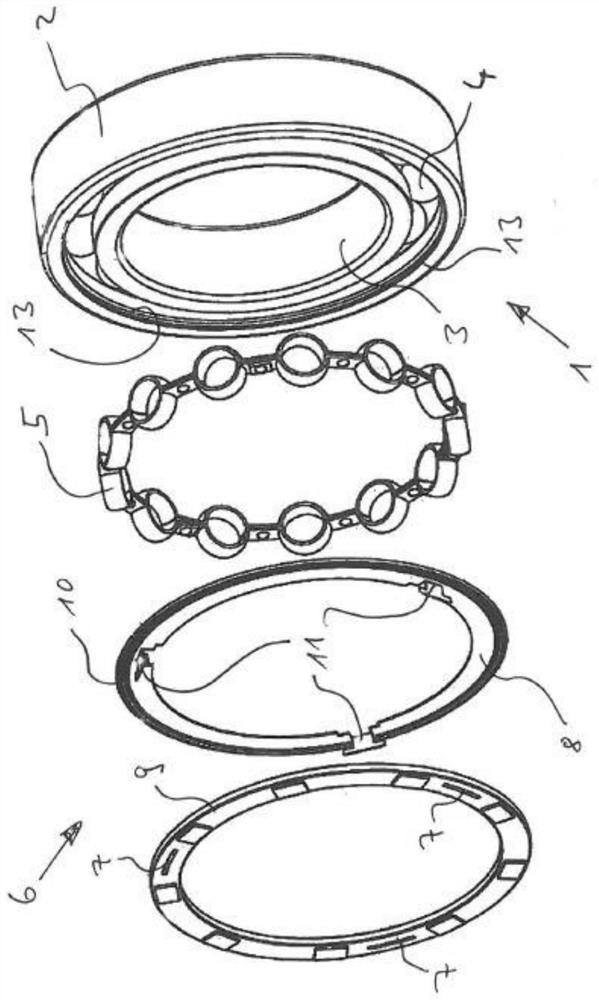

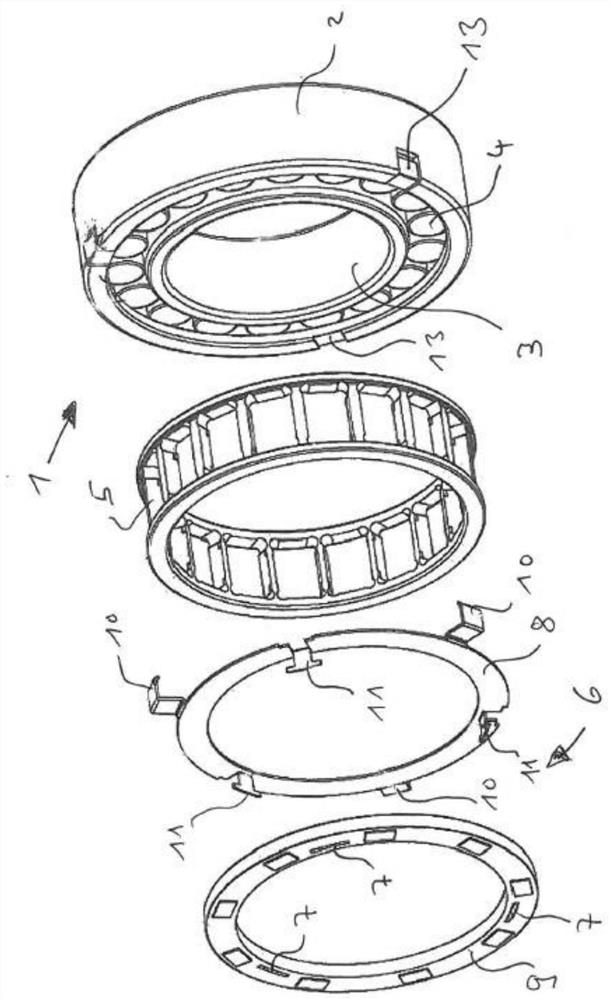

[0042] figure 1 A schematic exploded view of a first type of bearing 1 with a bearing monitoring system 6 according to the invention is shown, wherein the bearing housing and the shaft are not shown. The bearing 1 is composed of a first race 2 and a second race 3. In this design, the first race 2 is the outer race of the bearing and the second race 3 is the inner race of the bearing 1. The roller elements 4 are arranged between the first race 2 and the second ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com