Solid-liquid separation device for environment-friendly solid waste treatment

A solid waste, solid-liquid separation technology, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., to achieve the effect of increasing work efficiency, good effect and high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

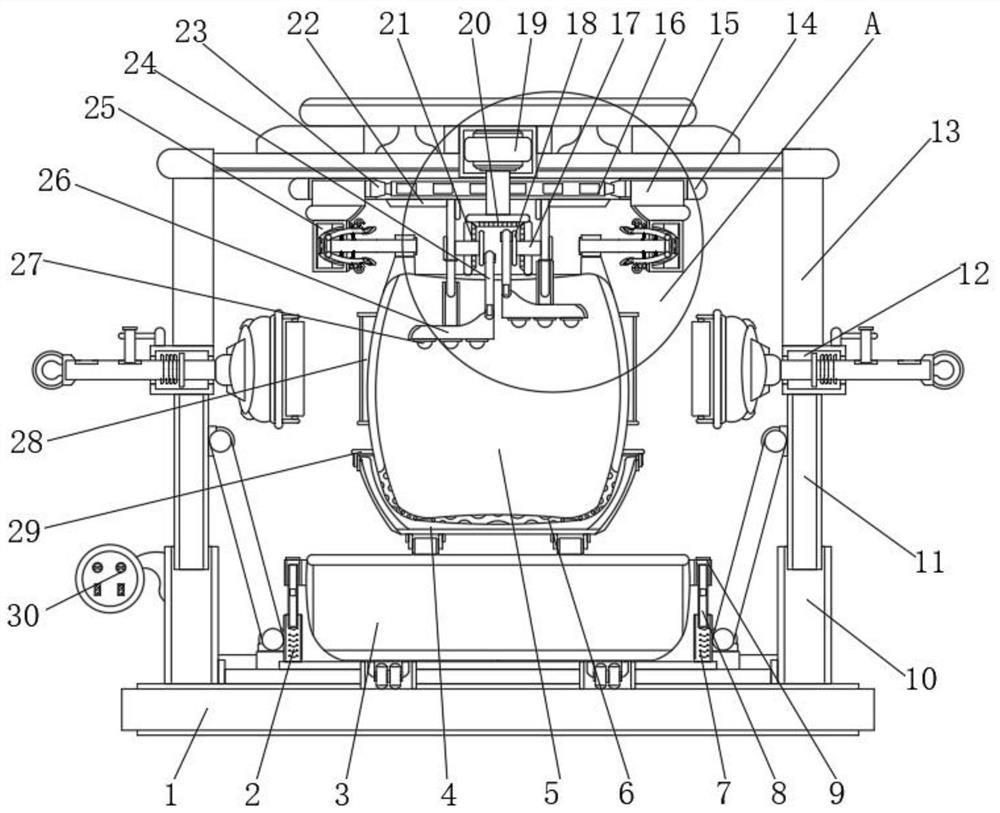

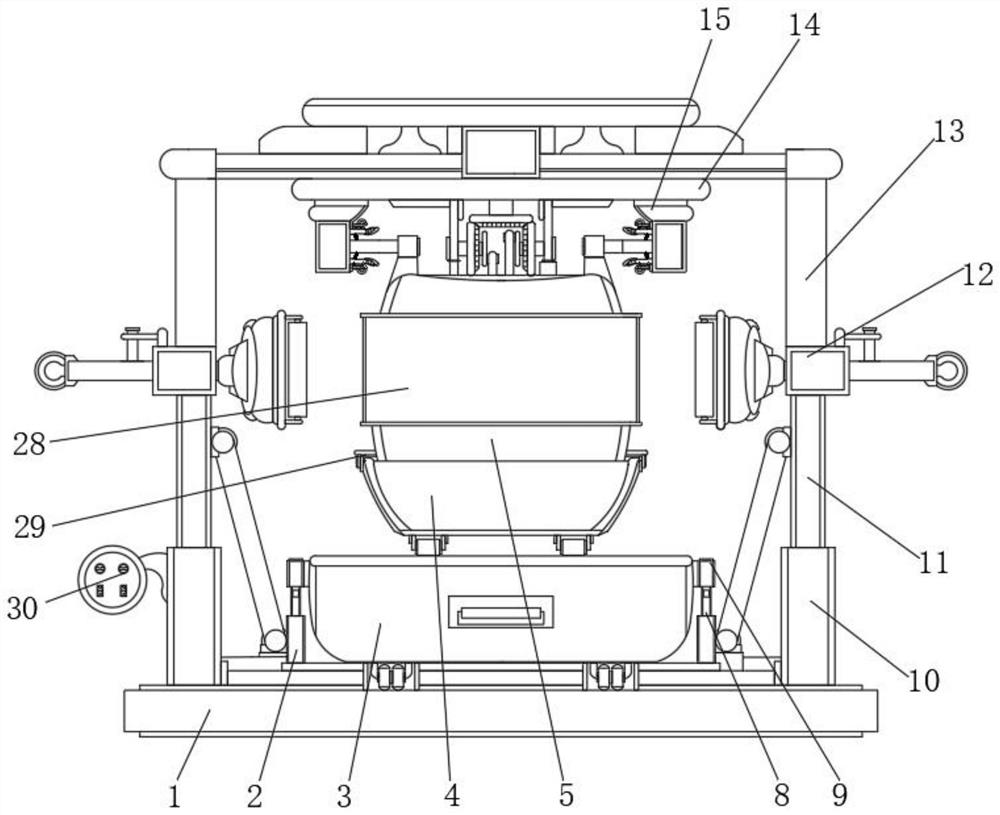

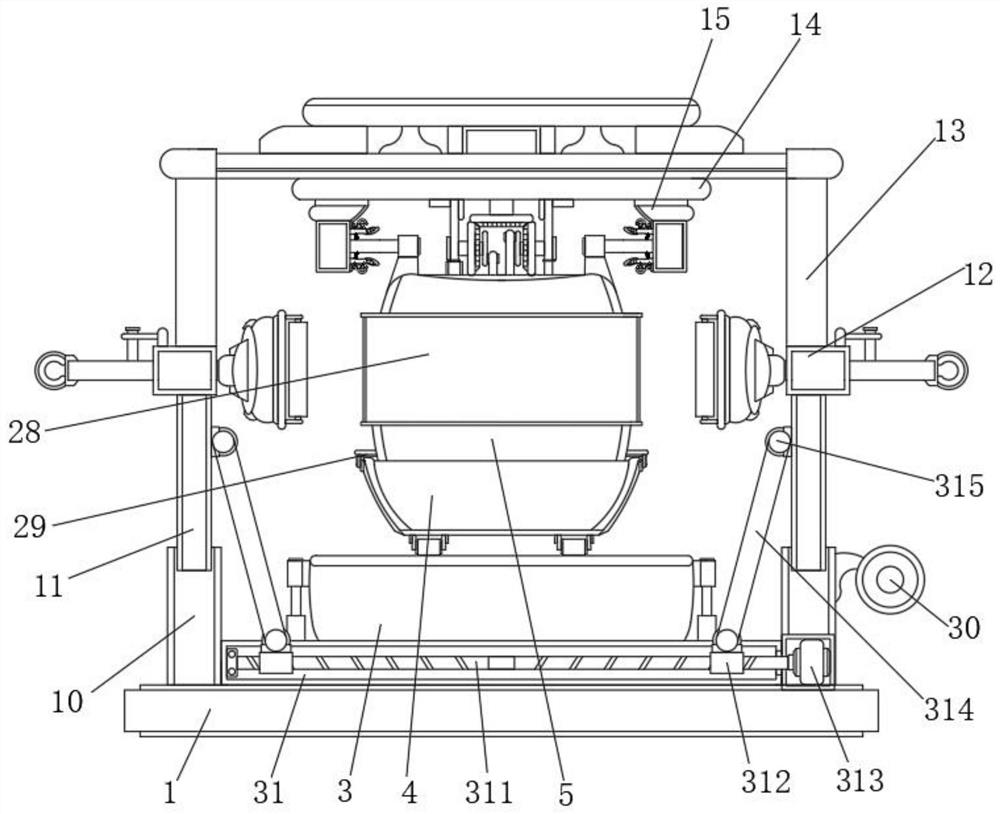

[0036] Example 1, such as image 3 with 4 As shown, when solid-liquid separation is required, the servo motor B313 can be started through the console 30, and the two-way threaded rod 311 is driven to rotate under the startup of the servo motor B313. , and then drive the hinged plate 314 to form a hinged fit with the hinged block 315, and pull the inner casing 11 to fall in the cooperation of the outer casing 10, so that the overall height of the U-shaped mounting frame 13 can be adjusted so that the filter layer 6 extends into the liquid-receiving In the tank 3, in this way, the water and liquid will not be scattered around during the solid-liquid cleaning work, which increases the collection effect of the water and liquid, and under the mutual cooperation of the boosting and rolling components, the rotation of the separation barrel 5 is effectively limited. The boosting effect further improves the separation efficiency of the device.

Embodiment 2

[0037] Example 2, such as Figure 5 with 9 As shown, when the separation bucket 5 needs to be disassembled and moved separately, first pull the movable hook 256 to cancel the hanging and fixing between the hanging ring 253, and then press two groups of arc clamps 254 to separate the movable hook 256 from the hanging ring 253, at the same time, cancel the engagement and fixation with the concave slot 25, and then pull the fixing rod 252 under the cooperation of the sleeve block 251, thereby canceling the installation position of the separation barrel 5, and use the buckle 33 to engage with the slot 29 The fixed structure makes it easy to wrap the liquid blocking tank 4 with the bottom of the separation barrel 5 to prevent the liquid from flowing out from the filter layer 6 and spilling on the ground, increasing the operability of the handling work. When performing solid-liquid separation, the liquid blocking tank 4 can be taken out Put it aside, and then click and assemble aga...

Embodiment 3

[0038] Example 3, such as Image 6 Buckle 33, when the separation barrel 5 needs to be installed, the pull rod 121 can be pulled to drive the spring B122 and the limit block 126 to compress and move, so that the pull rod 121 drives the clamping disc 125 to retract, which will not hinder the disassembly and assembly of the separation barrel 5 In this way, after the separation barrel 5 is fixed, the fixed position of the pull rod 121 is released, and the elastic restoring force of the spring B122 is used to drive the clamping disc 125, the rubber shock absorbing pad 123 and the rotating roller 124 to reset automatically, forming a clamping contact with the rolling groove 28. combined to achieve subsequent guide roll conditions and increase the functionality of the device.

[0039] Working principle: Connect the device to the power supply before use, start the servo motor A19 through the console 30, first press the positioning column 8 to extend downward with the cooperation of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap