Film forming agent and application thereof in semi-inorganic insulating coating liquid for silicon steel

A technology of insulating coating and film-forming agent, used in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as serious carcinogenicity, achieve good leveling and wettability, and improve magnetic properties. , the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

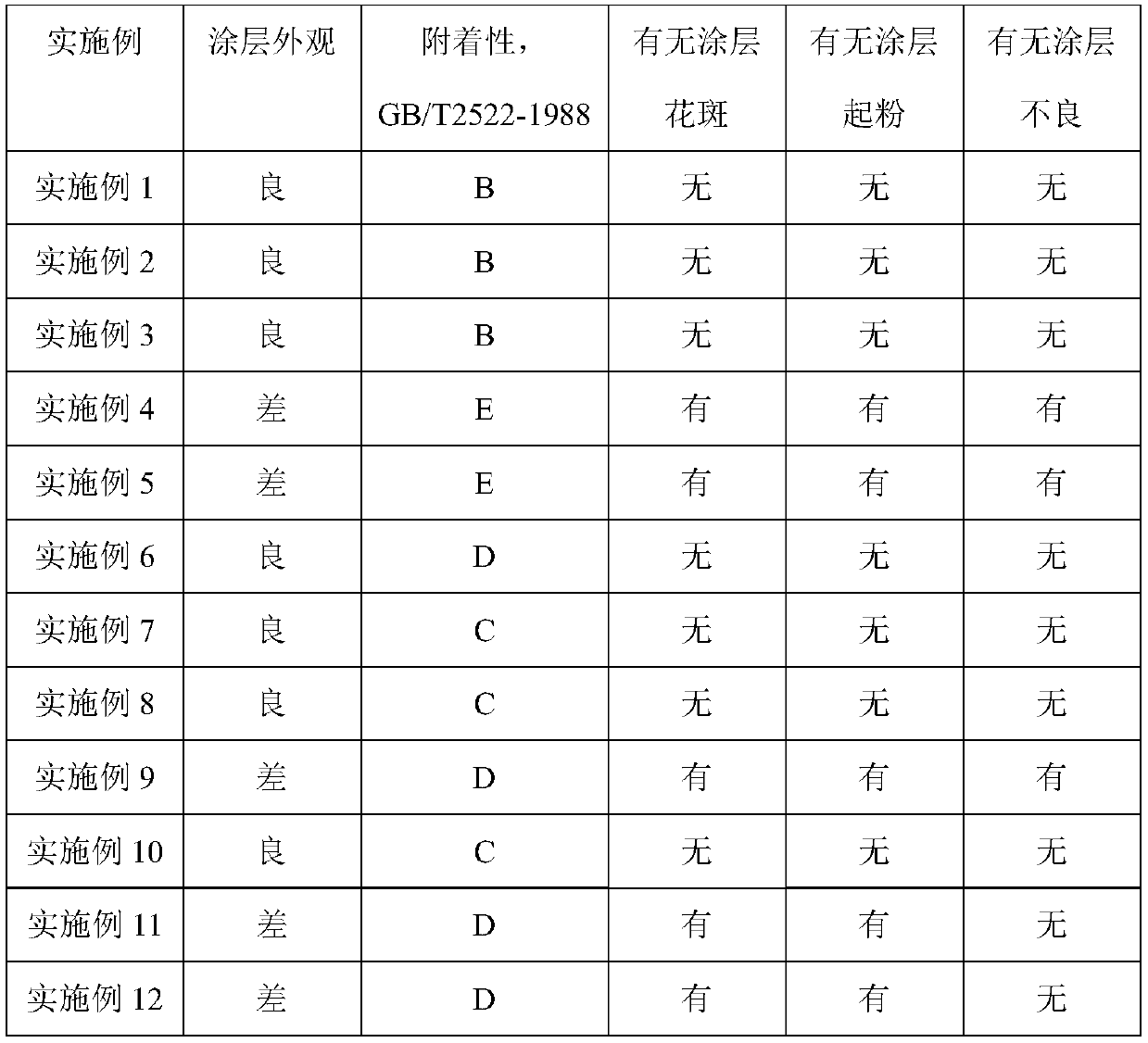

Examples

Embodiment approach

[0024] As an embodiment of the present invention, the film-forming agent is epoxy acrylic acid hybrid emulsion, and its preparation comprises the following steps:

[0025] (1) Preparation of pre-emulsion: add acrylic monomer and epoxy resin into the reaction vessel, stir and mix to obtain mixed monomer, then add water, emulsifier and initiator to it, stir and mix to obtain pre-emulsified liquid;

[0026] (2) Emulsion polymerization: Add water and emulsifier into the reaction vessel, heat up to 80-100°C, add the pre-emulsion obtained in step (1) dropwise to it, after the dropwise addition, keep warm for 1-5h, Post-treatment to obtain the epoxy acrylic hybrid emulsion.

[0027] As an embodiment of the present invention, the acrylic monomer is selected from methyl methacrylate, ethyl methacrylate, propyl methacrylate, isobutyl methacrylate, acrylic acid, methyl acrylate, ethyl acrylate One or more in ester, butyl acrylate; The emulsifier is an anionic emulsifier, preferably cet...

Embodiment 1

[0063] This embodiment provides a semi-inorganic insulating coating liquid for non-oriented silicon steel. In terms of mass percentage, the components of the insulating coating liquid include: 10% film-forming agent, 10% magnesium oxide, 0.1% water-based wax, Phosphoric acid / phosphoric acid ester inorganic substance 1%, compound containing rare earth element 0.1%, organic acid 0.1%, silica sol 1%, balance water.

[0064] In this embodiment, the film-forming agent is epoxy acrylic hybrid emulsion, and its preparation comprises the following steps:

[0065] (1) Preparation of pre-emulsion: Add methyl acrylate and epoxy resin NPEL 128 into the reaction vessel, stir and mix to prepare mixed monomer, then add deionized water, cetyl trimethyl chloride Ammonium, ammonium persulfate, so that the mass percentages of methyl acrylate, epoxy resin NPEL 128, cetyltrimethylammonium chloride and ammonium persulfate are respectively 0.7%, 18%, 2.5%, 1.8%, stirring Mix to obtain a pre-emulsio...

Embodiment 2

[0076] This embodiment provides a semi-inorganic insulating coating solution for non-oriented silicon steel. In terms of mass percentage, the components of the insulating coating solution include: 40% film-forming agent, 20% magnesium oxide, 5% water-based wax, Phosphoric acid / phosphoric acid ester inorganic matter 5%, compound containing rare earth element 3%, organic acid 3%, silica sol 5%, balance water.

[0077] In this embodiment, the film-forming agent and its preparation method are the same as in Embodiment 1.

[0078] In this embodiment, the magnesium oxide is light magnesium oxide, which is purchased from Sinopharm Group.

[0079] In this embodiment, the water-based wax is D-816, which is purchased from Keim, Germany, and its softening point is about 128°C; the average particle size is about 7 microns.

[0080] In this embodiment, the phosphoric acid / phosphate-containing inorganic substance is two kinds of aluminum dihydrogen phosphate and tris(trimethylsilyl)phospha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com