Energy-saving and environment-friendly treatment method for steel slag solid waste

A solid waste, energy-saving and environmental protection technology, applied in the methods, chemical instruments and methods, chemical/physical processes, etc. of using atmospheric pressure to chemically change substances, which can solve the problem of low efficiency and affect the aging effect and aging efficiency of steel slag. and other problems to achieve the effect of improving aging effect, saving time and energy, improving effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

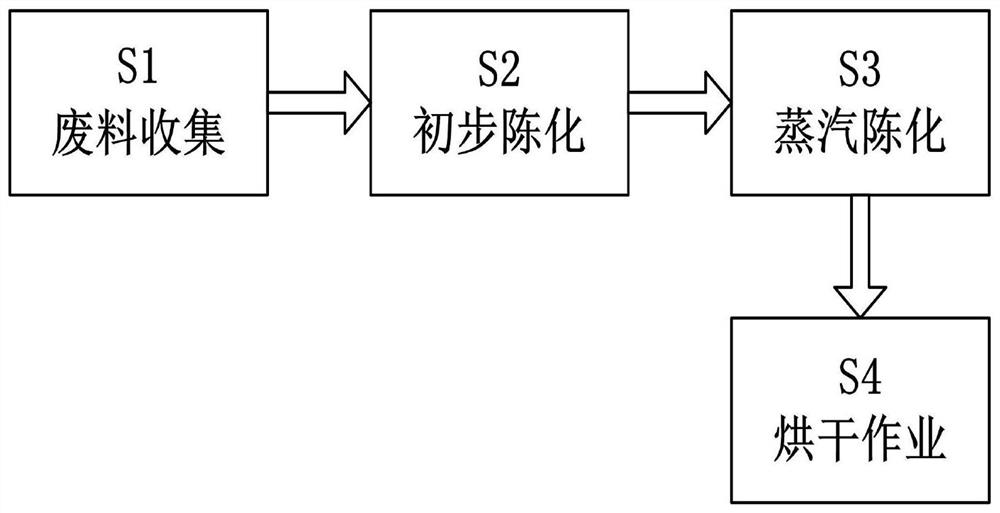

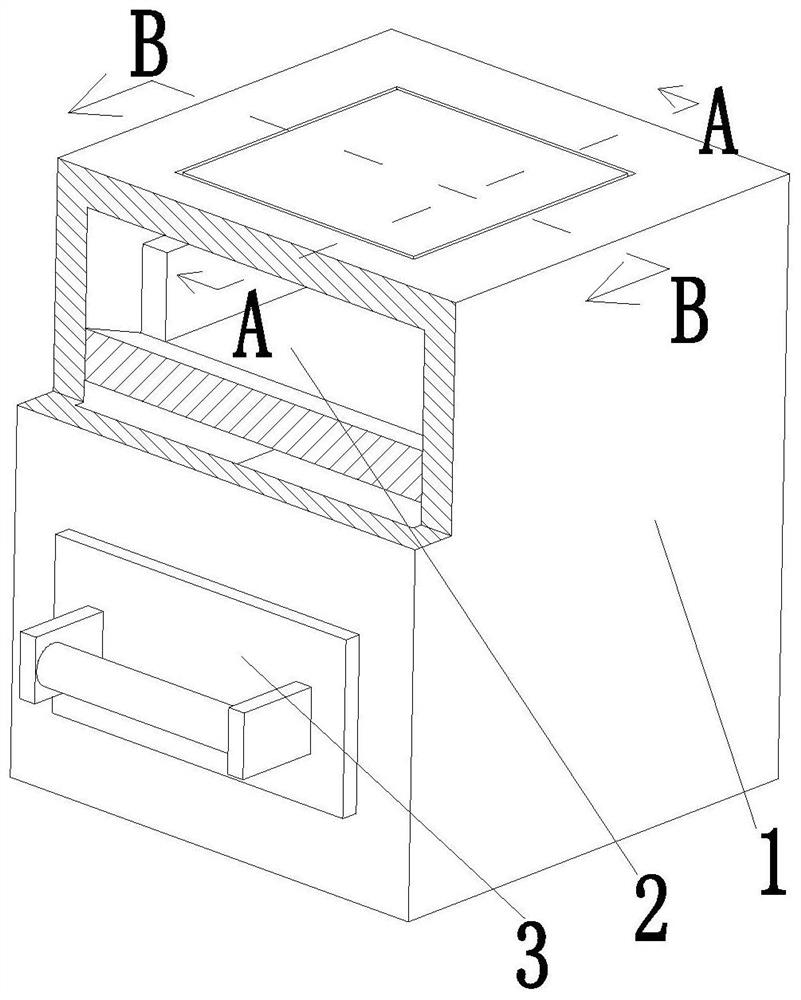

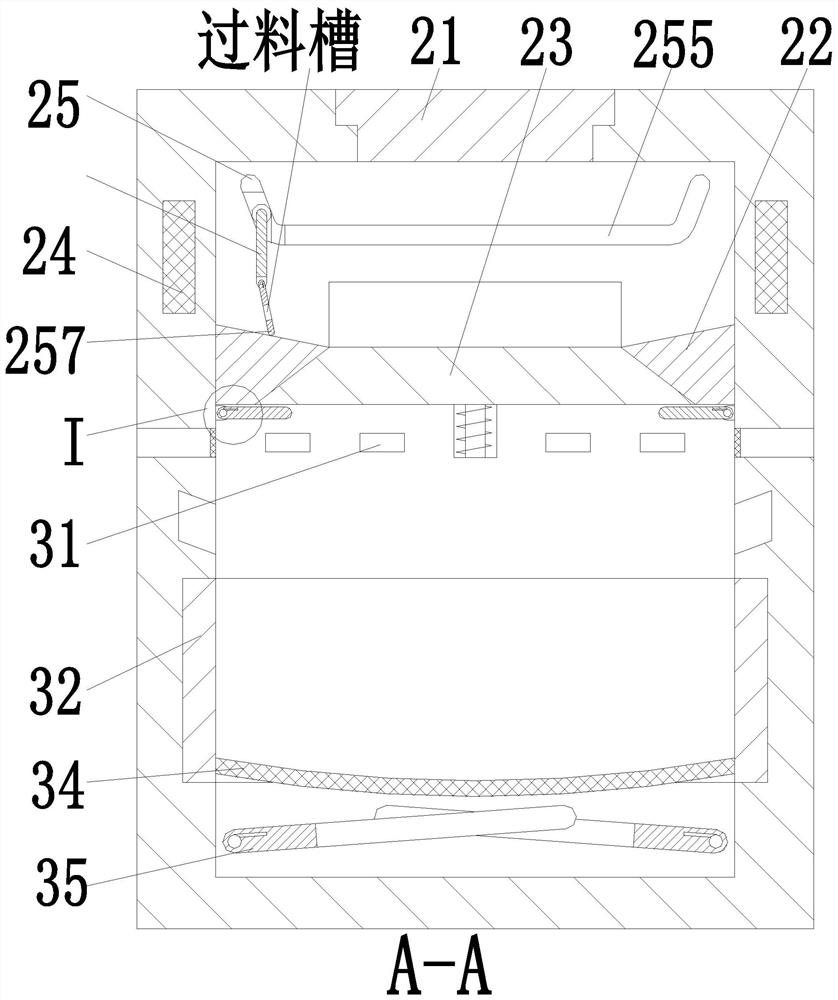

[0030] Such as Figure 1 to Figure 6 As shown, an energy-saving and environment-friendly treatment method for steel slag solid waste uses a high-temperature aging equipment, which includes a processing frame 1, a high-pressure aging device 2 and an auxiliary feeding device 3. The above-mentioned high-temperature aging The method for processing steel slag by chemical equipment also includes the following steps:

[0031] S1. Waste collection: steel slag is collected manually or mechanically;

[0032] S2. Preliminary aging: soaking steel slag in warm water for aging treatment;

[0033] S3. Steam aging: complete aging treatment of steel slag through steam aging equipment;

[0034] S4, drying operation: drying the aged steel slag to remove the moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com