Oil-resistant salt-resistant foaming agent

A technology of foaming agent and active agent, applied in the field of foaming agent, can solve the problems of easy defoaming, affecting the water-carrying function of the foaming agent, and reducing foam stability, and achieves the effect of high salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

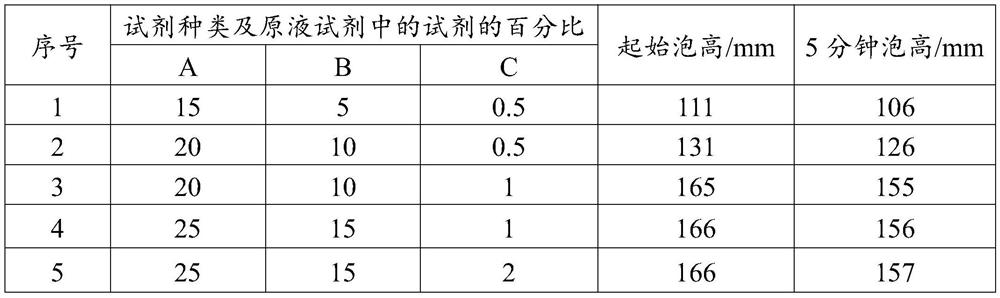

Embodiment 1

[0015] The anti-oil and anti-salt foaming agent of the present invention comprises the following components in weight percentage: 15% of nonionic surfactant, 5% of amphoteric surfactant, and 0.5% of fluorine-containing surfactant.

Embodiment 2

[0017] The anti-oil and anti-salt foaming agent of the present invention comprises the following components in weight percentage: 20% of nonionic surfactant, 10% of amphoteric surfactant, and 0.5% of fluorine-containing surfactant.

Embodiment 3

[0019] The anti-oil and anti-salt foaming agent of the present invention comprises the following components in weight percentage: 20% of nonionic surfactant, 10% of amphoteric surfactant, and 1% of fluorine-containing surfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com