A kind of crude oil viscosity reducer and preparation method thereof

A crude oil viscosity reducer and organic solvent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as the reduction and disappearance of emulsification ability, and achieve good emulsification and viscosity reduction ability, good viscosity reduction effect, The effect of high salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

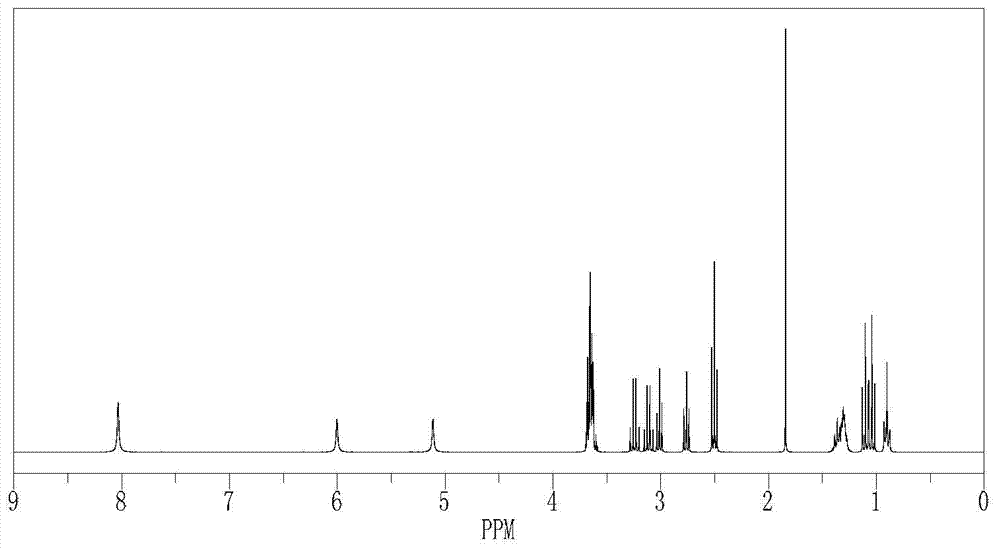

[0062] Embodiment 1, polymer shown in preparation formula I:

[0063] The end-modified polyamide-amine compound shown in formula I (the number of carbon atoms in the R main chain is 10, x=5, m=10) is prepared according to the following method:

[0064] 1) Preparation of long-chain alkyl 1.0G polyamide-amine (compound shown in formula IV):

[0065] Add 16g of decylamine (0.1mol) and 250g of methanol into a 1000mL three-necked flask, reflux at a constant temperature under magnetic stirring, and the bath temperature is 65°C. After the raw materials are completely dissolved, slowly add 86g (1mol) of methyl acrylate dropwise with a constant pressure dropping funnel , the dropping rate is one drop per second, after 24 hours of reaction under constant temperature (65°C) stirring, a light yellow transparent liquid is obtained. G (generation), add 3.3g (0.01mol) of 0.5G product in the there-necked flask, add 120g of methanol, and at a constant temperature of 60°C, while stirring, slow...

Embodiment 2

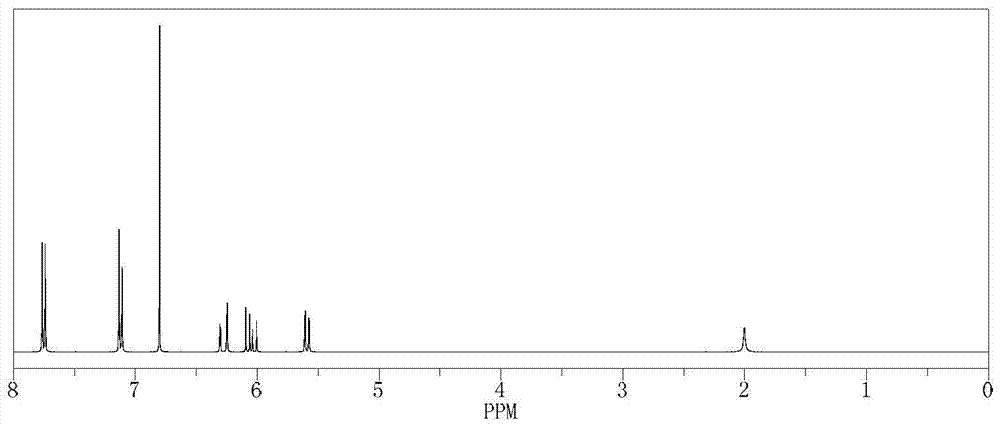

[0068] The preparation of the compound shown in embodiment 2, formula II:

[0069] 1) Preparation of 4-hydroxyethoxybenzenesulfonic acid: Dissolve 4.0g (0.1mol) NaOH (under alkaline conditions, the hydroxyl group of p-hydroxybenzenesulfonic acid is converted into an oxyanion to attack the bromine site of bromoethanol) in 100mL In distilled water, cool to room temperature and add to a three-necked flask; add 6.9g (0.05mol) p-hydroxybenzenesulfonic acid, stir and dissolve in the above sodium hydroxide solution, and heat to 80°C in a water bath; add a little KI to the flask, add a little KI The purpose is to catalyze and accelerate the reaction. The reaction is carried out at a temperature of 80°C, the reaction time is 20h, and the reaction has already occurred. The amount of KI added is 5% of that of bromoethanol, and the added KI is essentially a catalyst. First, let I- replace the Br- of bromoethanol, iodine The reactivity of ethanol is higher than that of bromoethanol, which...

Embodiment 3

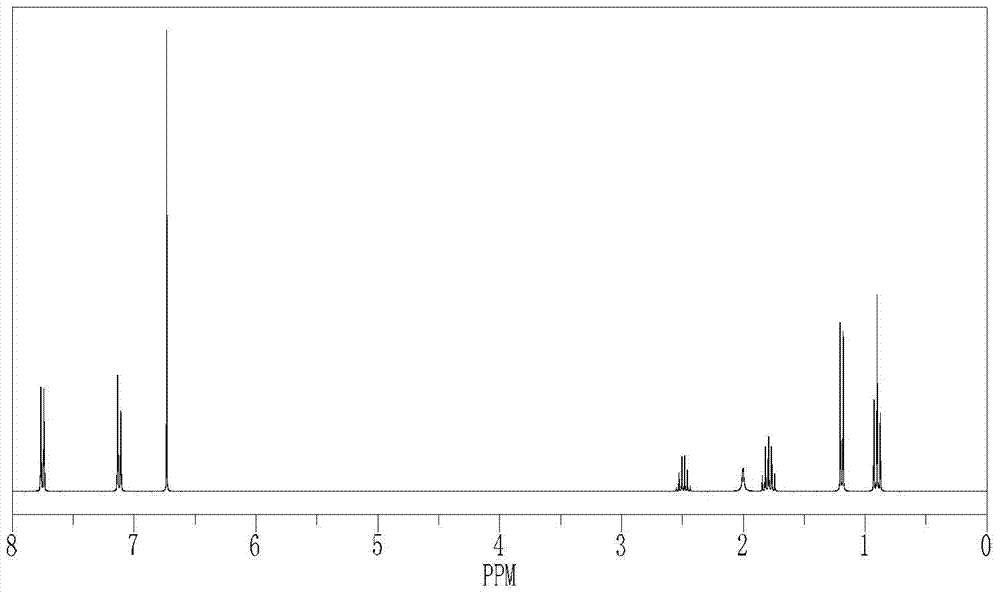

[0078] Embodiment 3, crude oil viscosity reducer P 1 Preparation of:

[0079] The polymer of formula II-1 obtained in Example 1 and the end-modified 1.0-generation polyamide-amine compound shown in formula I (the number of carbon atoms in the R main chain is 10, x=5, m=10) are respectively prepared into aqueous solutions, Then, mix at a solute mass ratio of 1:1 to prepare a compound system solution of the end-modified 1.0-generation polyamide-amine compound shown in formula I and the polymer shown in formula II, with a total concentration of 2.0 g / L, denoted for P 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com