Fracturing fluid thickening agent and preparation method thereof

A technology of thickening agent and fracturing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as no good solutions, and achieve strong anti-degradation characteristics, strong stability, strong rigidity and The effect of salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

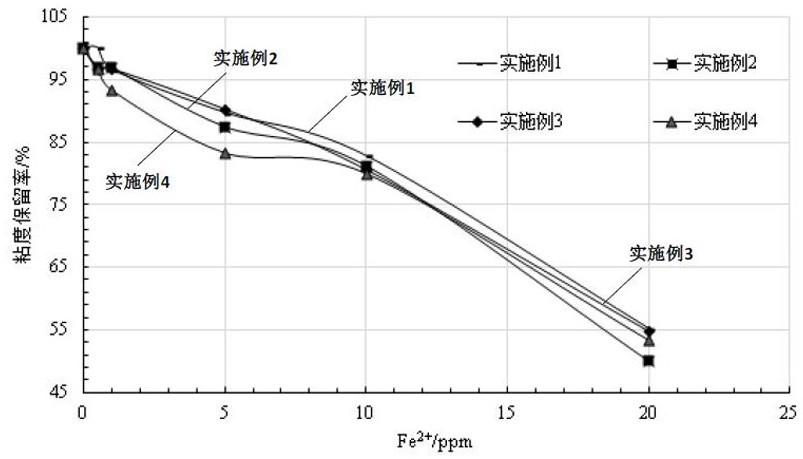

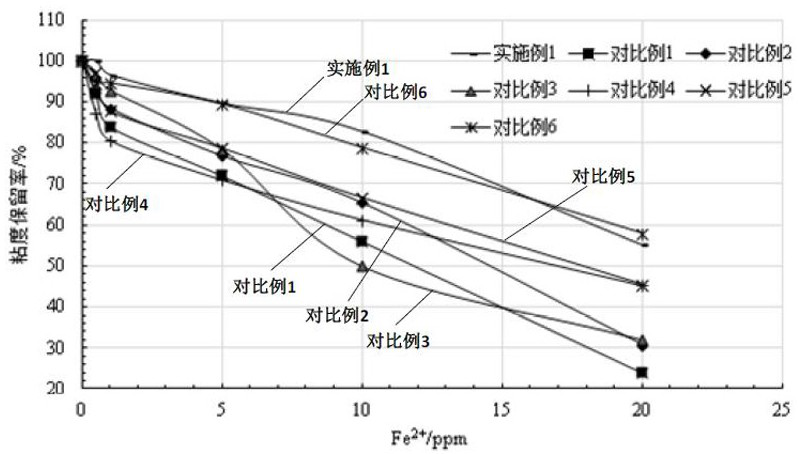

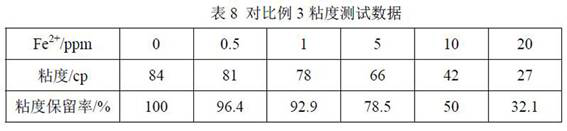

Examples

preparation example Construction

[0032] The present invention provides a kind of preparation method of fracturing fluid thickener in the first aspect, described method uses acrylamide as raw material, and comprises the following steps:

[0033] (1) Preparation of internal water-based phase

[0034] Using acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, strength monomers, self-assembly monomers, stabilizers and water as raw materials, the inner water-based phase is prepared;

[0035] (2) Preparation of oil-based phase

[0036] Using white oil, emulsifier and film-forming aid as raw materials, the oil-based phase is prepared:

[0037] (3) Preparation of internal phase emulsion polymerization product

[0038] Add the internal water-based phase, oil-based phase and oxidizing agent in sequence to the mixing tank, stir and mix evenly, then transfer to the reaction tank, pass nitrogen gas to remove oxygen, and then add an initiating amount of the first reducing agent to initiate the polymerization reaction to ...

Embodiment 1

[0076] This embodiment prepares a fracturing fluid thickener, the amount of raw materials is in parts by weight, and the preparation method includes the following steps:

[0077] (1) Preparation of the inner water-based phase:

[0078] The internal water-based phase is prepared from the following raw materials in parts by weight: 10 parts by weight of acrylamide, 100 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid, and 200 parts by weight of sodium 4-acryloylbenzenesulfonate as a strength monomer Parts, 1 part by weight of perfluorooctyl ethyl methacrylate (purchased from Shangfluorine Technology, the same below) as self-assembled monomer, 5 parts by weight of citric acid as stabilizer, used to regulate the hydrogenation of pH value 19 parts by weight of sodium, and 200 parts by weight of water. The preparation process is as follows: Add acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, sodium 4-acryloylbenzenesulfonate, perfluorooctylethyl methacrylate, cit...

Embodiment 2

[0090] This embodiment prepares a fracturing fluid thickener, the amount of raw materials is in parts by weight, and the preparation method includes the following steps:

[0091] (1) Preparation of the inner water-based phase:

[0092] The internal water-based phase is prepared from the following raw materials in parts by weight: 25 parts by weight of acrylamide, 150 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid, 250 parts by weight of methacrylamide ethyl ethylene urea as a strength monomer Parts by weight, 2 parts by weight of 2-(perfluorohexyl) ethyl methacrylate as a self-assembled monomer, 7 parts by weight of citric acid as a stabilizer, 28 parts by weight of sodium hydroxide for adjusting the pH value, water 250 parts by weight. The preparation process is as follows: Add acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, methacrylamide ethyl ethylene urea, 2-(perfluorohexyl) ethyl methacrylic acid in sequence in the mixing tank Esters, citric acid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com