Dike for equipment of manufacturing and processing semiconductor and LCD

一种加工设备、半导体的技术,应用在半导体/固态器件制造、应用、家用元件等方向,能够解决熔融环氧树脂泄漏、堤防工作所需的时间变长、强度变弱等问题,达到确保坚固性、节省堤防设置费用、提高利用效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The embodiments described in the description of the present invention and the structures shown in the accompanying drawings belong to preferred embodiments of the present invention, and do not represent all technical ideas of the present invention. Therefore, it should be understood that various equivalents replacing them may be included at the time of this application.

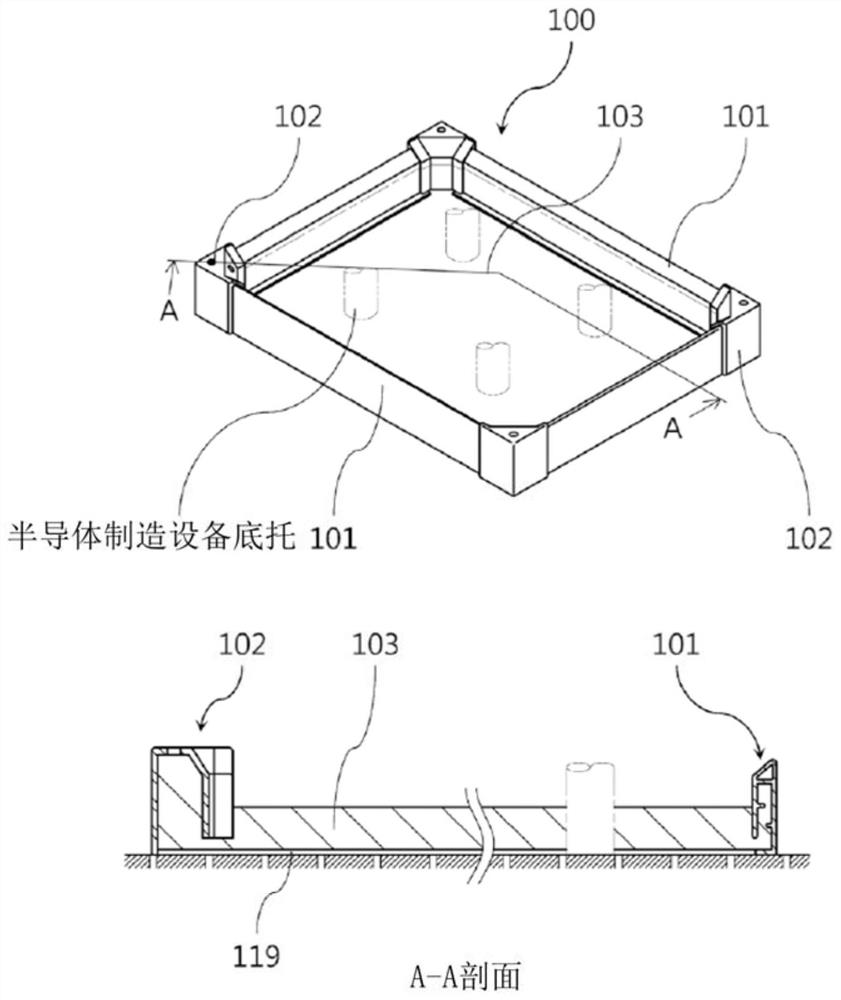

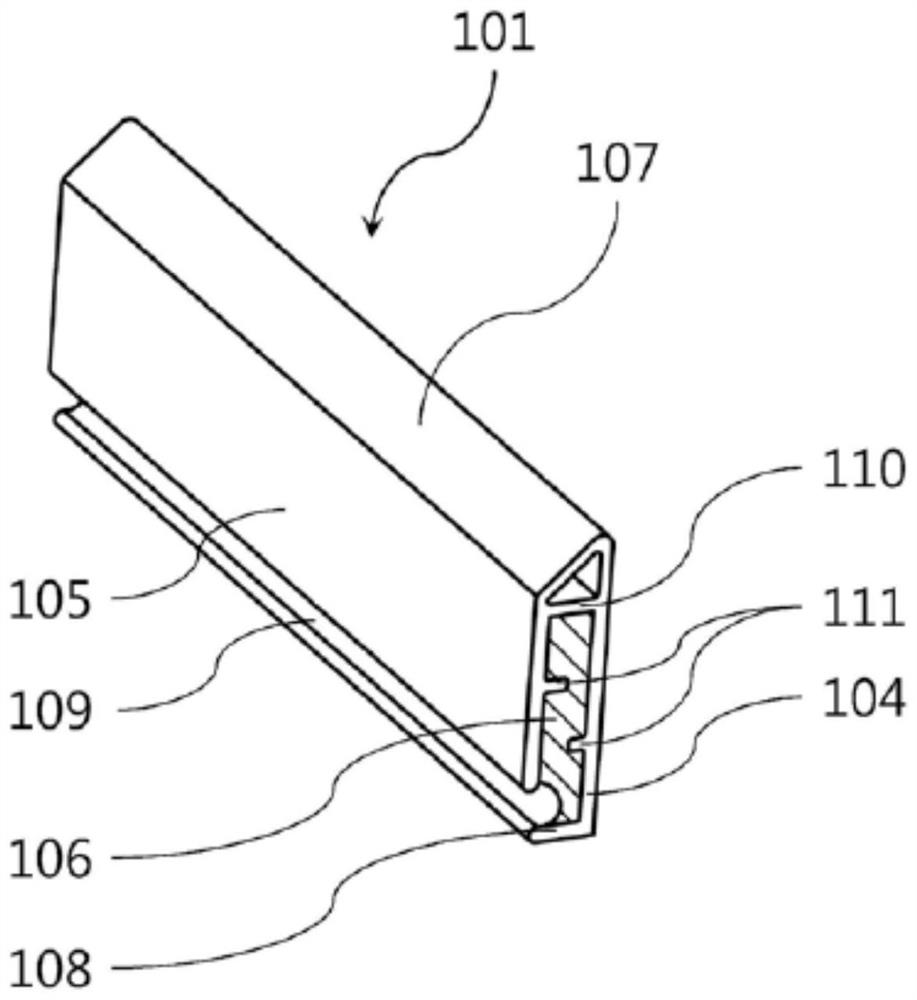

[0050] The embankment for semiconductor manufacturing equipment according to the present invention will be specifically described below with reference to the accompanying drawings. In describing the invention, the same names and symbols are used for components that perform the same functions as those in the prior art.

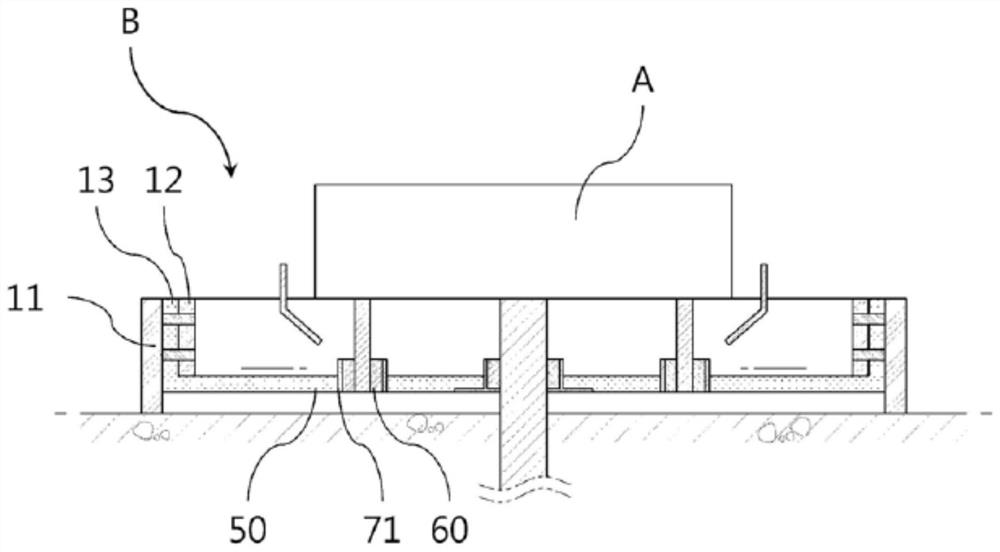

[0051] Such as figure 2 As shown, the present invention relates to an embankment that receives and collects leaked or scattered liquid from semiconductor manufacturing equipment installed at the bottom of a porous building and recycles it. The embankment 100 has a predetermined height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com