Track linkage type automatic production testing mechanism

A production testing and linkage technology, applied in electronic circuit testing, printed circuit testing, electrical measurement, etc., to solve the problem of compatibility and flexible production, fast positioning and pressing, and obvious mechanism effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

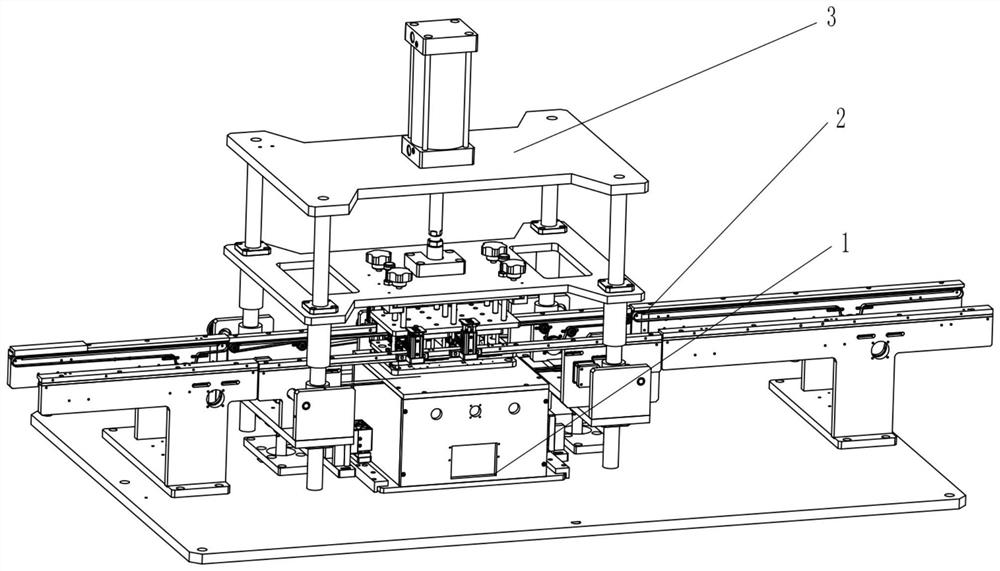

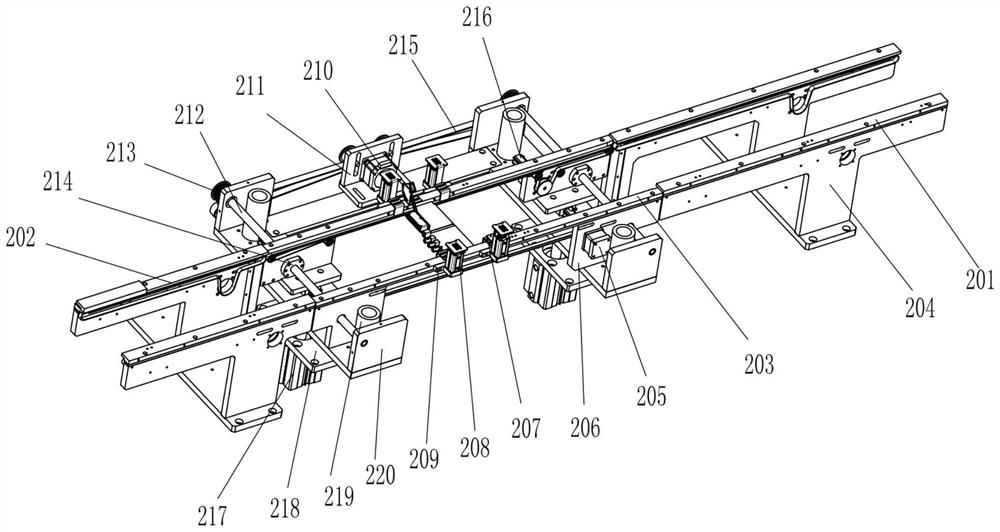

[0027] combine Figure 1~4 , 6, 7 illustrate that the automated production testing mechanism of the present embodiment includes a needle bed assembly 1, an assembly line assembly 2 and a press-down cylinder assembly 3;

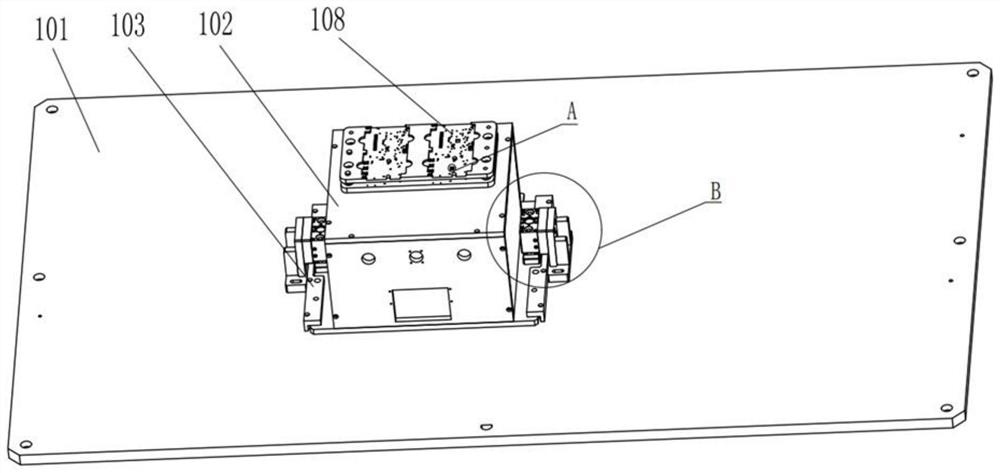

[0028] The needle bed assembly 1 includes a tooling base plate 101, a needle bed box 102, two sets of needle bed box installation blocks 103, two sets of needle bed fixed cylinders 104, two sets of first cylinder installation fixing plates 105, and two sets of cylinder adapter plates 106 , two groups of needle bed boxes fixed pressing block 107, circuit board profiling block 108, micro switch 109 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com