An overvoltage clamp circuit

A clamping circuit and overvoltage technology, applied in electrical components, output power conversion devices, etc., can solve the problems of limited circuit application range and difficulty in frequency compensation, and achieve high stability, easy frequency compensation, and low load regulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

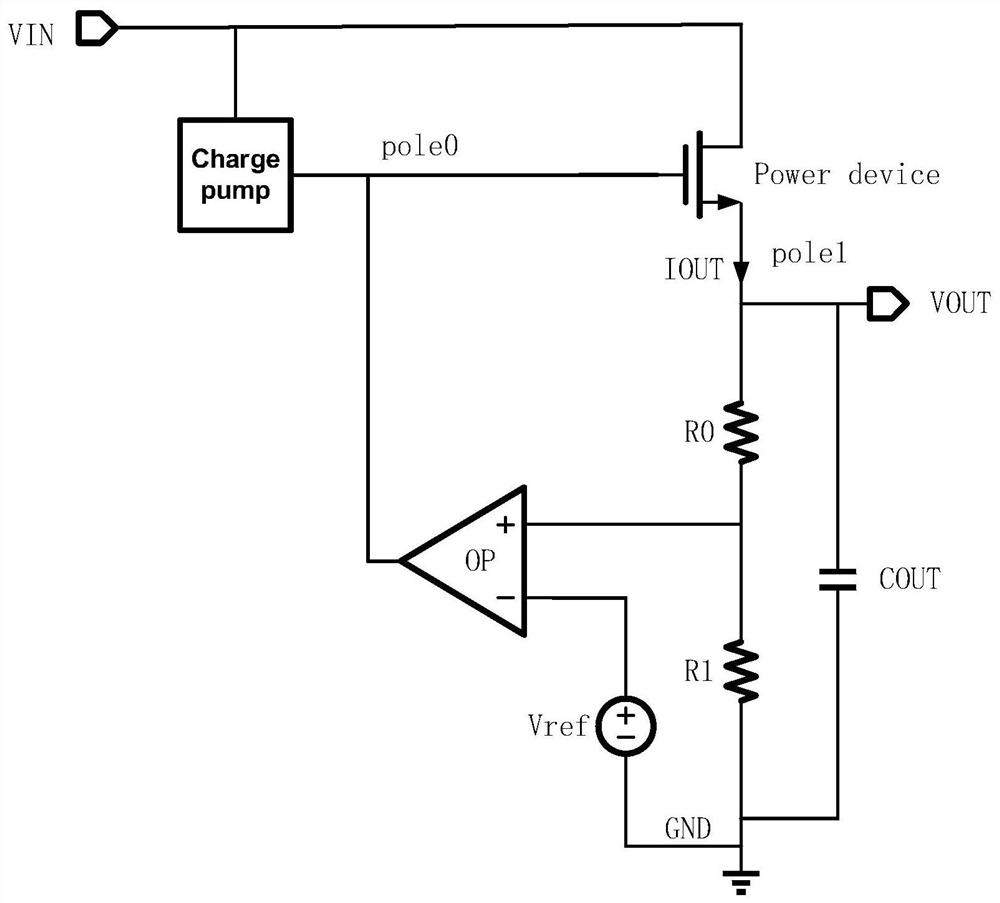

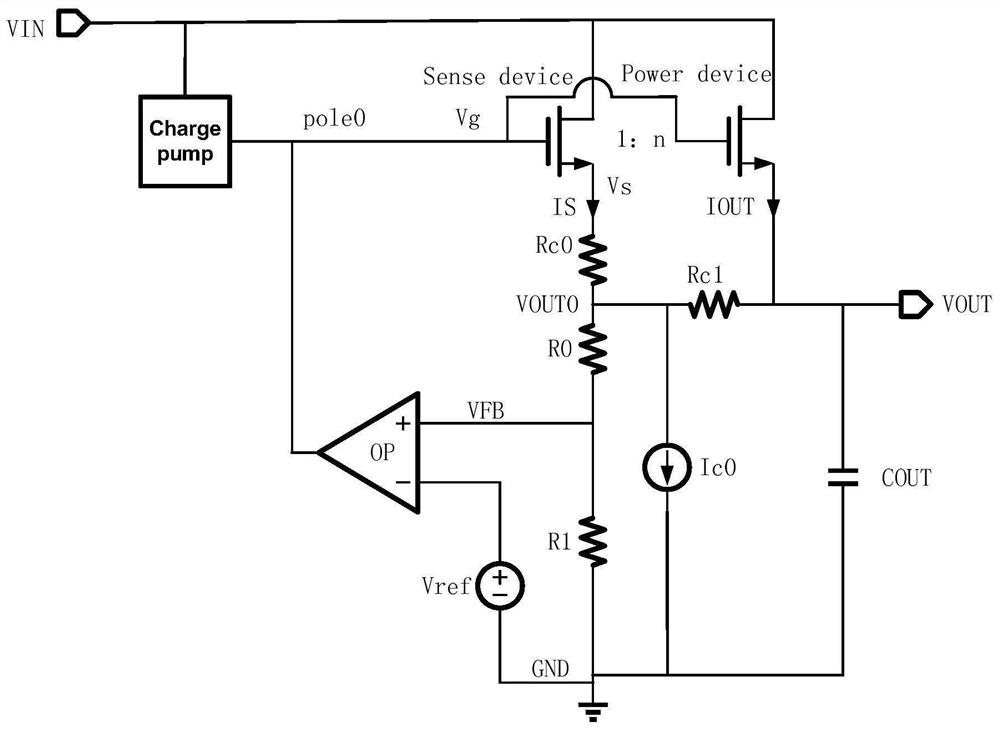

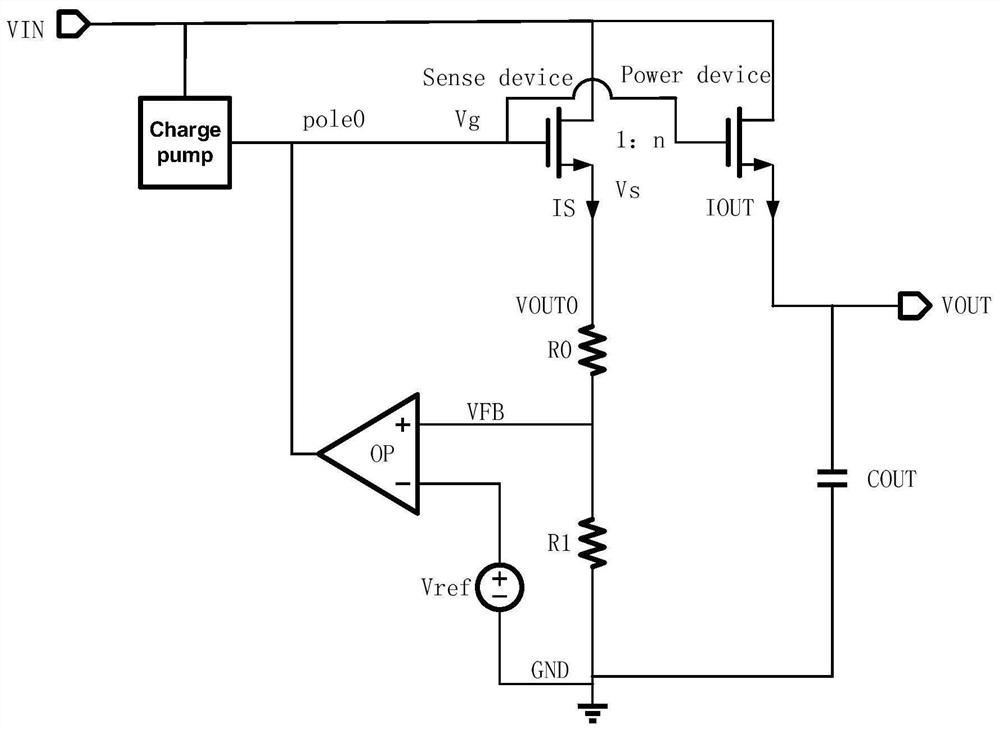

[0020] Below with the accompanying drawings ( Figure 2-Figure 5 ) to illustrate the present invention.

[0021] figure 2 It is a structural schematic diagram of an overvoltage clamping circuit implementing the present invention. image 3It is another structural schematic diagram of an overvoltage clamping circuit implementing the present invention. Figure 4 yes image 3 Schematic diagram of waveforms of medium voltage nodes Vg, Vs, VOUT0, VOUT, Vgs0, Vgs1 changing with output current IOUT. Figure 5 It is a structural schematic diagram of the third example of implementing an overvoltage clamping circuit of the present invention. Such as Figure 2 to Figure 5 As shown, an overvoltage clamping circuit includes an input voltage terminal VIN connected to the drain of the NMOS power transistor Power device and an output voltage terminal VOUT connected to the source of the NMOS power transistor Power device, and the output voltage terminal VOUT is output through the The cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com