Flying dust treatment device for construction site

A construction site and output device technology, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of working environment and excessive dust that affect workers' construction, and achieve complete functions, reasonable and simple structure, Improve the effect of area and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

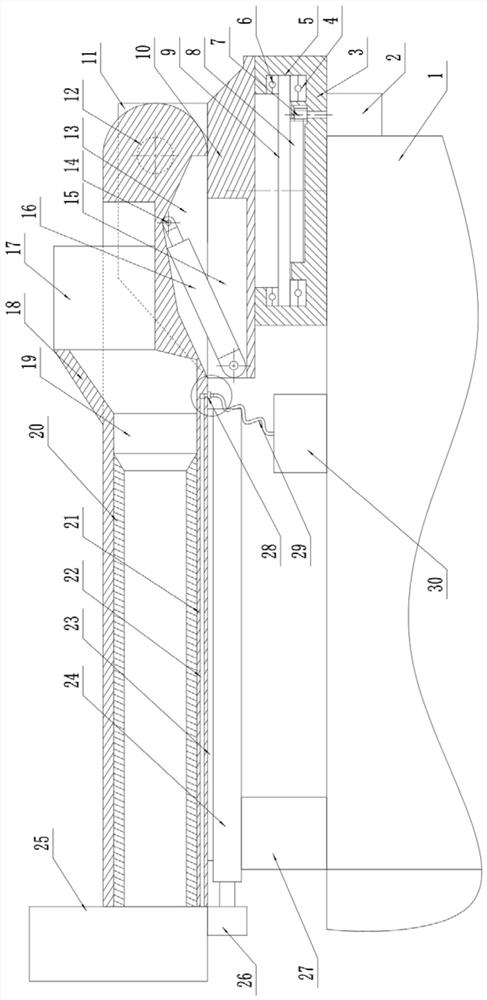

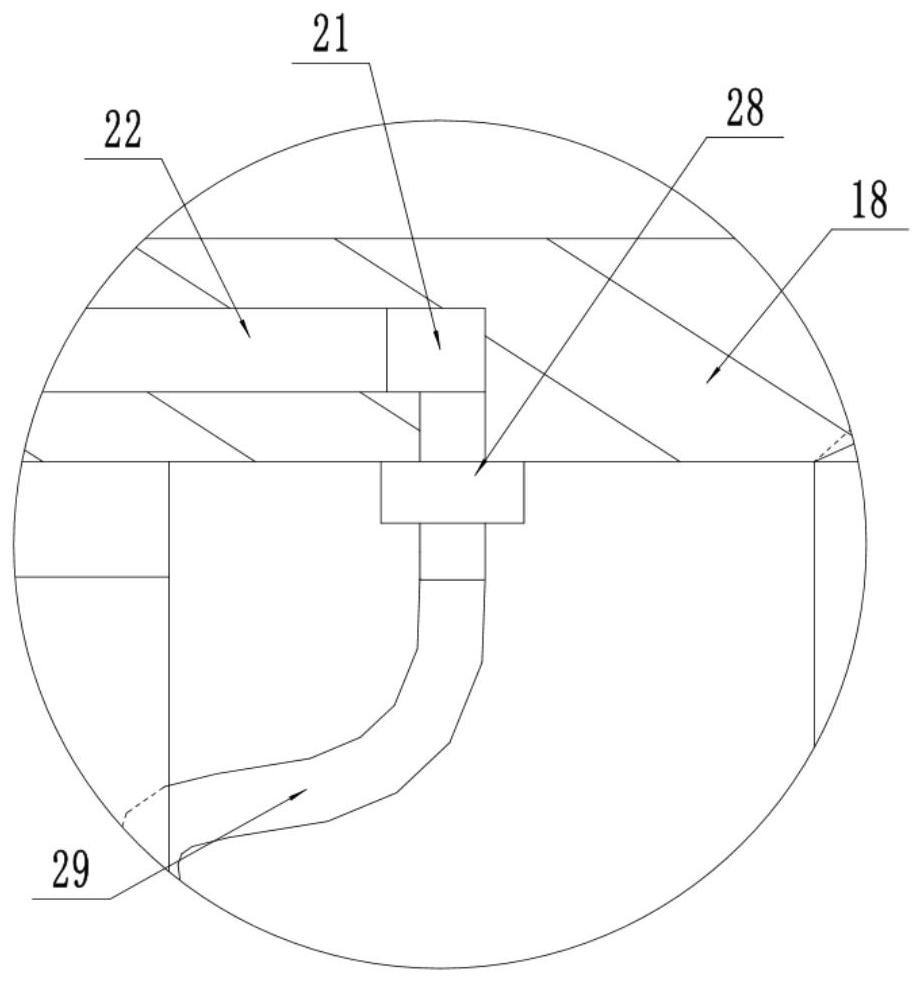

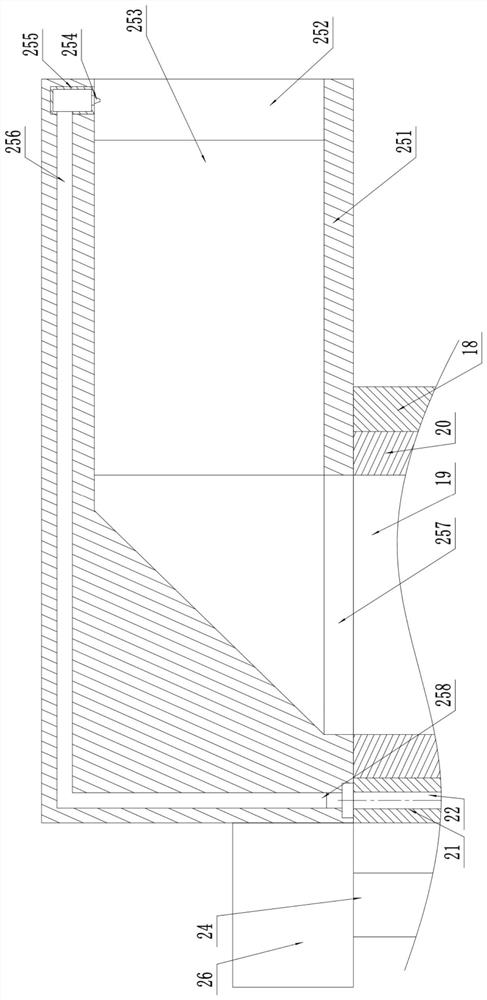

[0020] Such as figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: a dust control device for construction sites, including a mobile water tank 1, and also includes a motor 2, a fixed seat 3, a lower bearing 4, a connecting groove 5, an upper bearing 6, an active Gear 7, driven gear 8, rotating seat 9, connecting seat 10, mounting groove 11, fixed shaft 12, groove one 13, connecting shaft one 14, groove two 15, oil cylinder one 16, blower 17, outer shell 18, Air duct 19, inner casing 20, guide hole 21, movable pipe 22, connecting bar 23, oil cylinder 2 24, output device 25 and connecting block 26; the left side of the bottom of the fixed seat 3 is fixedly connected to the top surface of the mobile water tank 1 On the right side, a connection groove 5 is provided in the upper side of the fixed seat 3; a rotating seat 9 is movably connected inside the connecting groove 5; a driven gear 8 is fixedly connected to the center of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com