Crescent-shaped and deformed ceramic microparticles, its preparation method, application and preparation device

A technology for preparing devices and ceramic micro-particles, applied in chemical instruments and methods, liquid separation into bead droplets and granulation, chemical/physical/physical-chemical processes of applying energy, etc. Uniform size and precise and controllable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

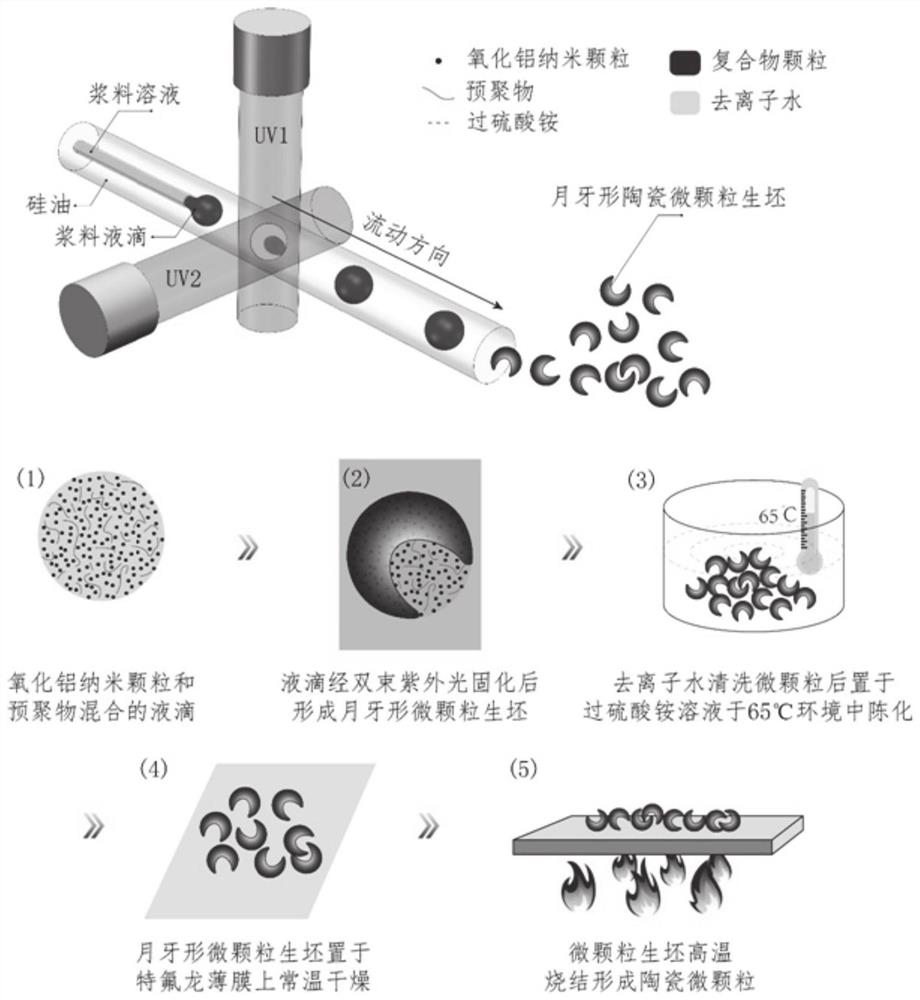

[0036] In a second aspect, the present invention provides a method for preparing crescent-shaped and deformed ceramic microparticles, comprising the steps of:

[0037] Pass the internal phase fluid into the external phase fluid in the external phase glass tube through the internal phase glass tube;

[0038] Under the shear action of the external phase fluid, the internal phase fluid forms water-in-oil emulsified droplets at the outlet of the internal phase glass tube, and the droplets flow through the cross exposure area of the two beams of ultraviolet light with the liquid flow;

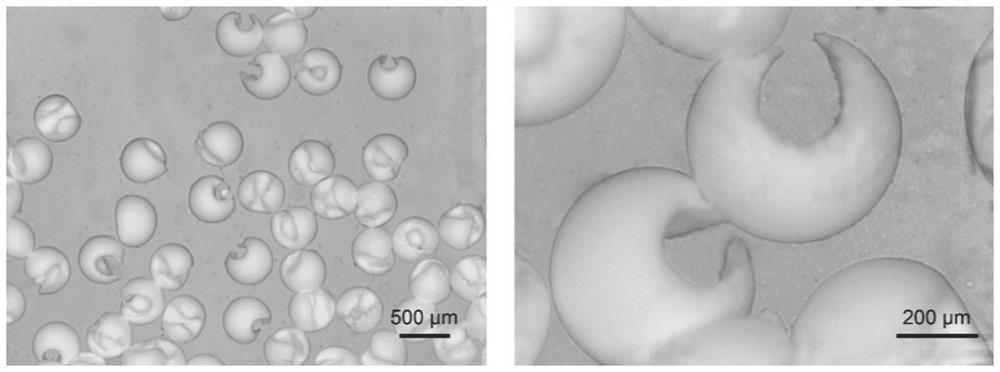

[0039] The inner phase fluid droplets are collected through exposure and solidification, and then cleaned, dried, cross-linked, aged, and sintered to obtain crescent-shaped and deformed ceramic microparticles.

[0040] The present invention is one of the key technologies for double-beam UV curing of opaque droplets. At present, in the method of preparing microparticles based on microfluidic UV cur...

Embodiment 1

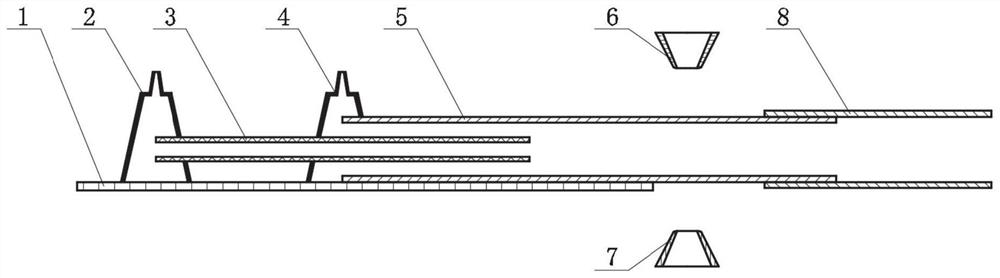

[0061] refer to figure 1 , an example of a device for preparing crescent-shaped and deformed ceramic microparticle green bodies based on the microfluidic chip design of the present invention, including: a bottom plate 1, a first dispensing needle 2, an internal phase glass tube 3, and a second point Glue needle 4, external phase glass tube 5, first ultraviolet lamp head 6, second ultraviolet lamp head 7 and collection hose 8; The first dispensing needle 2 and the second dispensing needle 4 are fixed side by side on the base plate 1, and the One port of the inner glass tube 3 communicates with the cavity of the first dispensing needle 2, one port of the outer glass tube 5 communicates with the cavity of the second dispensing needle 4, and the other of the inner glass tube 3 One port extends into the outer phase glass tube 5 after passing through the cavity of the second dispensing needle 4; the first ultraviolet lamp head 6 is placed directly above the outer phase glass tube 5;...

Embodiment 2

[0067] A device for preparing crescent-shaped and deformed ceramic microparticle green bodies based on a microfluidic chip, the difference is that it also includes injectors for injecting the inner phase fluid and the outer phase fluid respectively, and the first dispensing The needle 2 and the second dispensing needle 4 are respectively connected with a syringe, and the respective syringes are driven by a flow pump, so as to inject the internal phase fluid and the external phase fluid into the first dispensing needle 2 and the second dispensing needle 4 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com