A Printing Method of Functional Micro-Nano Heterostructure

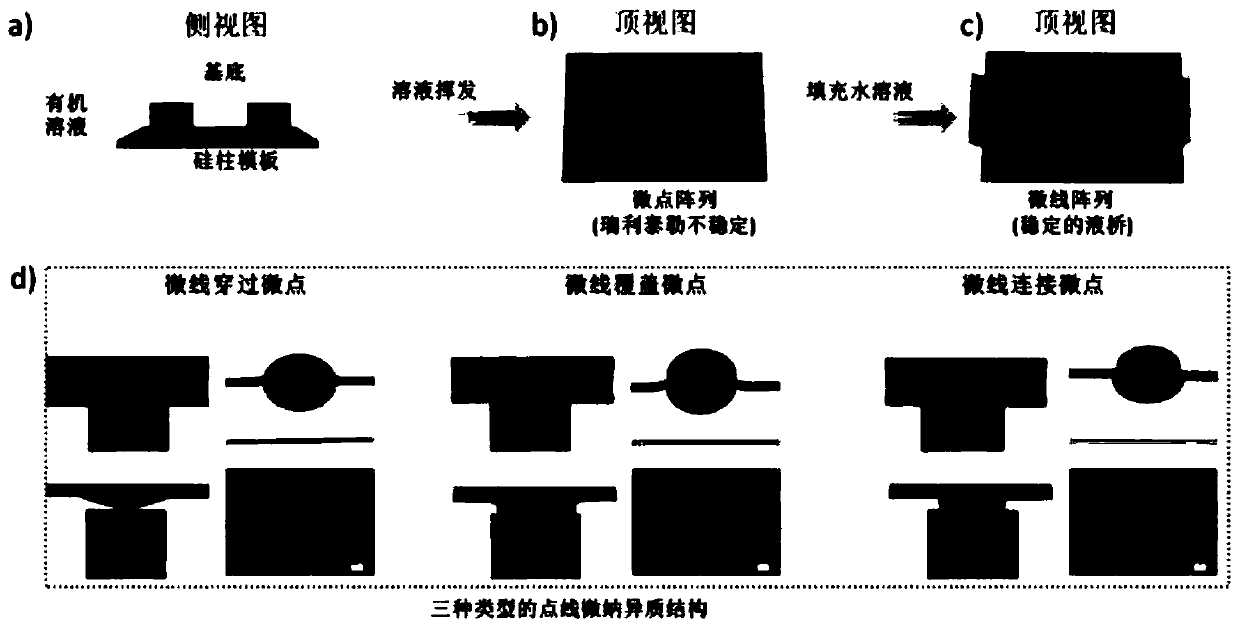

A printing method and heterostructure technology, which is applied in the printing field of functional micro-nano heterostructures, can solve the problems of chaotic connection methods of heterogeneous structures, difficulty in controlling solutions, etc., and achieve the effect of precise and controllable interface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

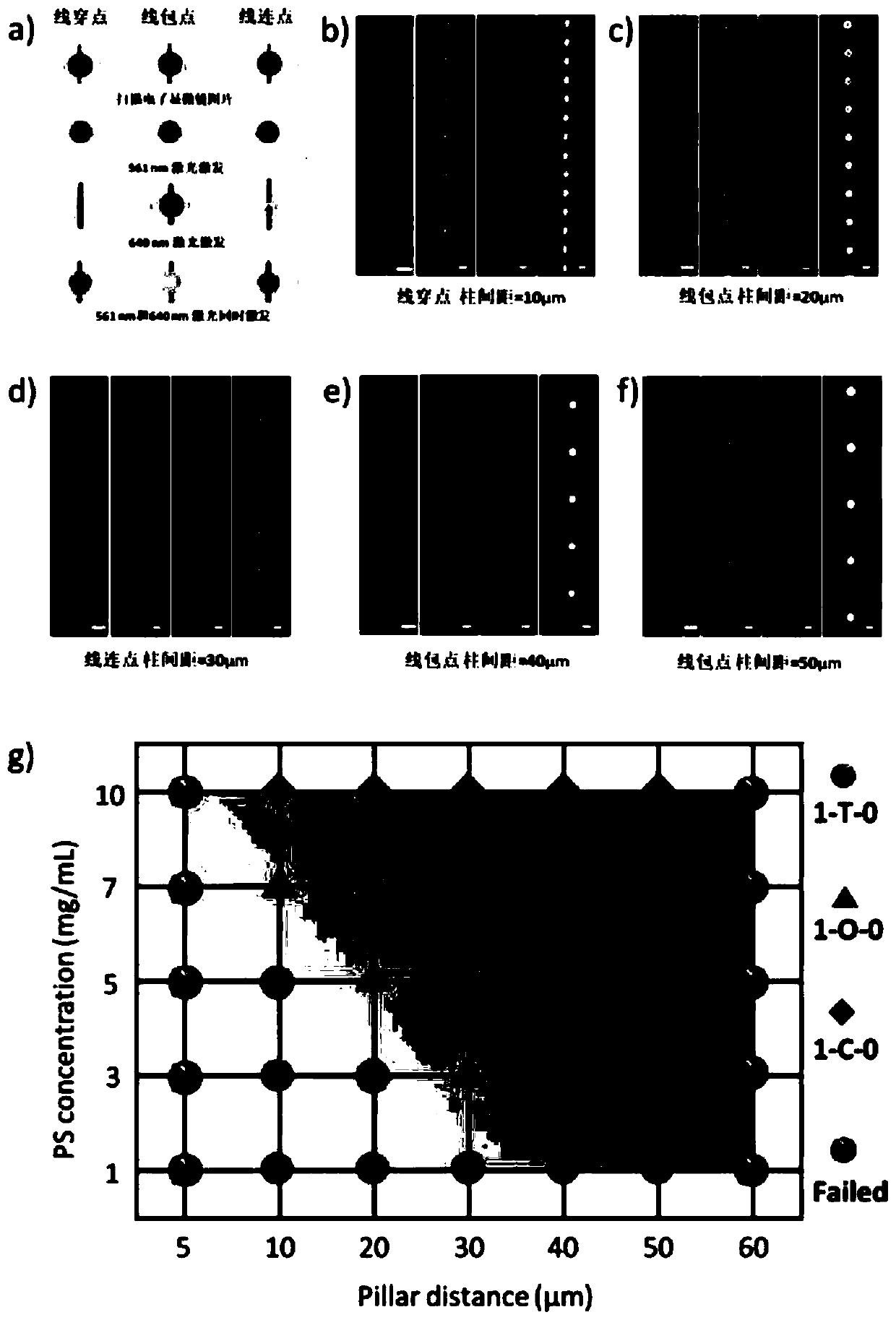

Embodiment 1

[0039] The mass content of CdS prepared by CdS quantum dots with a particle size of 5nm, polystyrene and o-dichlorobenzene is 0.2%, the mass content of polystyrene is 0.1%, and the balance is o-dichlorobenzene. Take 10 microliters from the liquid gun and spread it evenly on the photolithographic circular silicon column template; cover the silicon substrate on the silicon column template covered with the assembly solution, and let the solvent evaporate evenly at 80°C; take out the device and let it cool at room temperature, and again Inject 10 microliters of the assembly solution prepared by CdS quantum dots with a particle size of 5nm, polyvinyl alcohol, sodium lauryl sulfate and water, wherein the mass content of CdS is 0.2%, and the mass content of polyvinyl alcohol is 0.5%. The mass content of sodium alkyl sulfate is 0.2%, and the balance is water, so that the solvent is uniformly volatilized at 50° C., and after the water in the assembly solution volatilizes, a silicon wafe...

Embodiment 2

[0041] The mass content of CdS prepared by CdS quantum dots with a particle size of 5nm, polystyrene and o-dichlorobenzene is 0.2%, the mass content of polystyrene is 0.5%, and the balance is o-dichlorobenzene. Take 10 microliters from the liquid gun and spread it evenly on the photolithographic circular silicon column template; cover the silicon substrate on the silicon column template covered with the assembly solution, and let the solvent evaporate evenly at 80°C; take out the device and let it cool at room temperature, and again Inject 10 microliters of the assembly solution prepared by CdS quantum dots with a particle size of 5nm, polyvinyl alcohol, sodium lauryl sulfate and water, wherein the mass content of CdS is 0.2%, and the mass content of polyvinyl alcohol is 0.5%. The mass content of sodium alkyl sulfate is 0.2%, and the balance is water, so that the solvent is uniformly volatilized at 50° C., and after the water in the assembly solution volatilizes, the silicon ch...

Embodiment 3

[0043] The mass content of CdS prepared by CdS quantum dots with a particle size of 5nm, polystyrene and o-dichlorobenzene is 0.2%, the mass content of polystyrene is 1%, and the balance is o-dichlorobenzene. Take 10 microliters from the liquid gun and spread it evenly on the photolithographic circular silicon column template; cover the silicon substrate on the silicon column template covered with the assembly solution, and let the solvent evaporate evenly at 80°C; take out the device and let it cool at room temperature, and again Inject 10 microliters of the assembly solution prepared by CdS quantum dots with a particle size of 5nm, polyvinyl alcohol, sodium lauryl sulfate and water, wherein the mass content of CdS is 0.2%, and the mass content of polyvinyl alcohol is 0.5%. The mass content of sodium alkyl sulfate is 0.2%, and the balance is water, so that the solvent is uniformly volatilized at 50°C, and after the water in the assembly solution is volatilized, a micro-nano st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com