An experimental preparation device and method for frustum-shaped porous pegda microparticles

A technology for preparing a device and microparticles, which is applied in the field of experimental preparation devices for porous PEGDA microparticles, can solve problems such as limiting the development and application of microparticles, and achieve the effect of precise and controllable shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

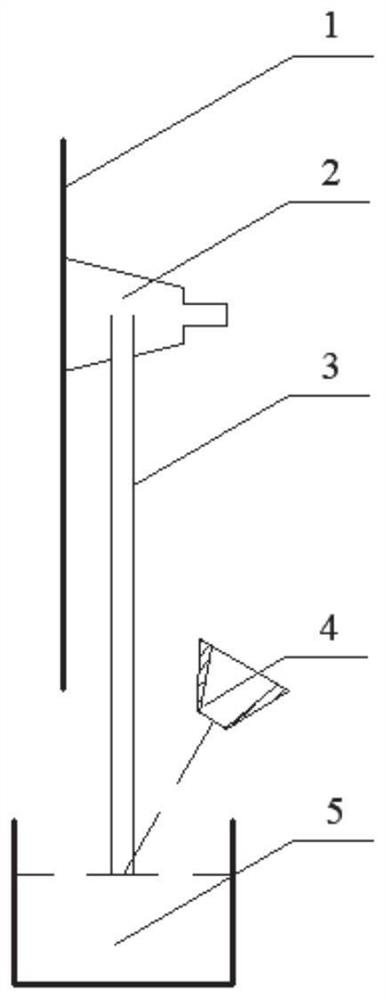

[0031] refer to figure 1 , an example of the present invention based on the phase separation technology to prepare the experimental device of conical porous PEGDA microparticles, comprising: comprising a base plate 1, a dispensing needle 2, a capillary glass tube 3, an ultraviolet lamp 4 and a collection dish 5; the dispensing needle 2 is fixed on the base plate 1, the bottom plate 1 hangs directly above the collection dish 5; the collection dish 5 is used to contain the oil phase; the upper port of the capillary glass tube 3 communicates with the cavity of the dispensing needle 2, and the lower port of the capillary glass tube 3 The port is in contact with the air-oil phase interface of the collecting vessel 5; the ultraviolet lamp head 4 is placed towards the lower port of the capillary glass tube 3, and the two intersect at a set angle.

[0032] Further, the device for preparing truncated conical porous PEGDA microparticles based on phase separation technology also includes...

Embodiment 2

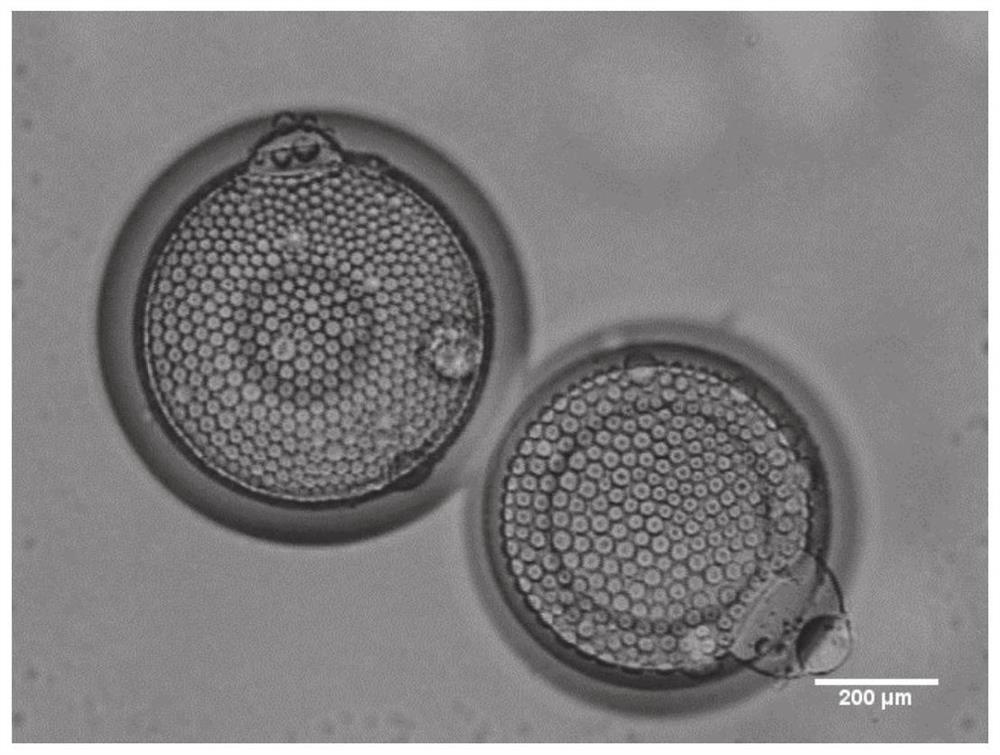

[0038] Such as figure 2 As shown, the present embodiment also provides a method for preparing truncated conical porous PEGDA microparticles based on phase separation technology, comprising the steps of:

[0039] 1. Preparation of eutectic liquid: at room temperature, mix 0.02ml hydroxyl-2-methylpropiophenone, 1ml PEGDA, and 3ml glycerin, add 1.5ml absolute ethanol dropwise to the resulting mixed solution, and vortex for 5 minutes to obtain eutectic liquid .

[0040] 2. Preparation of the oil phase: Measure 10ml of liquid paraffin and 0.2ml of Span80, mix and vortex for 5 minutes to obtain the oil phase.

[0041] 3. The preparation of frustum-shaped porous PEGDA microparticles is carried out using the device described in Example 1, specifically:

[0042](1) Inject the eutectic liquid prepared in this embodiment into the dispensing needle through a syringe, and when the eutectic liquid drips into the oil phase from the capillary glass tube and is suspended at the air-oil phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com