Urban underground pipeline repairing device

A technology for underground pipelines and cities. It is applied in the direction of spraying devices, devices for coating liquid on the surface, and cleaning hollow objects. It can solve problems such as long repair time, easy fall off of repair glue, and easy re-breakage of damaged pipes, etc., to speed up repairs. Drying efficiency, accelerated drying effect, and uniform effect of repair glue application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

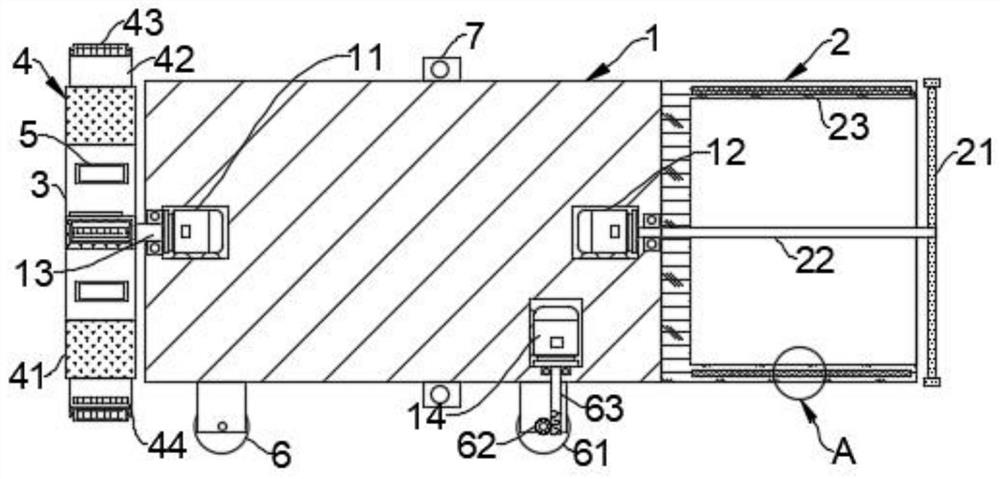

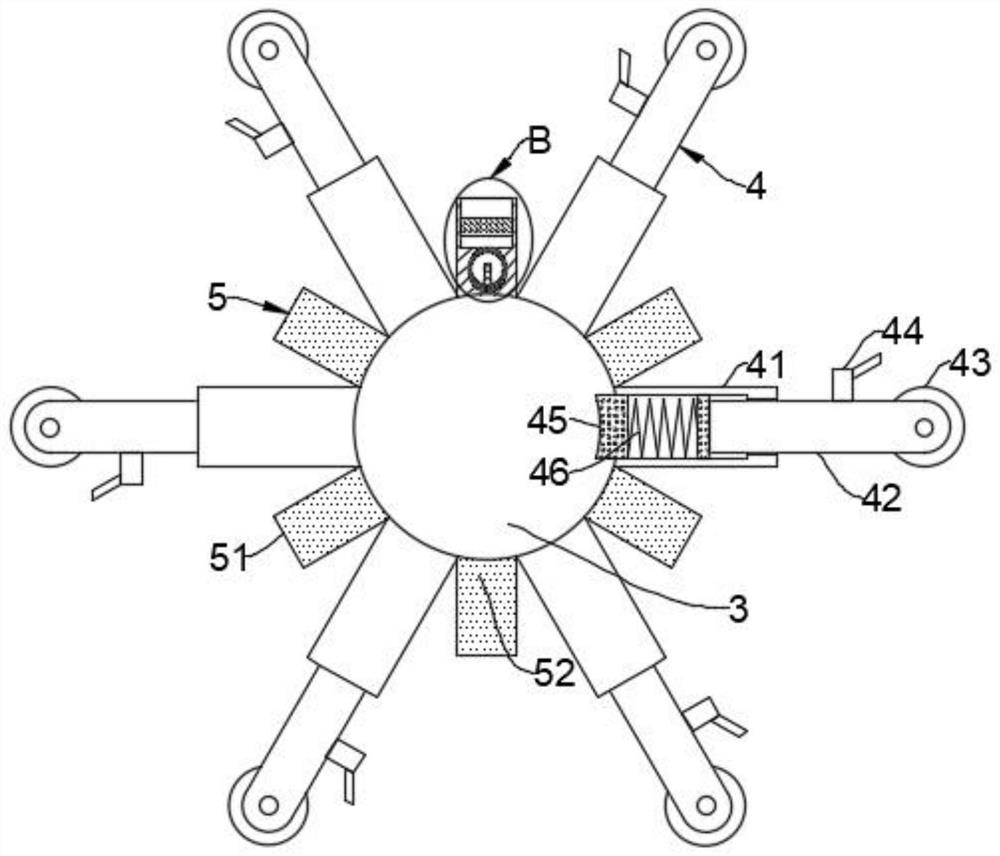

[0024] Such as Figure 1-6 As shown, an urban underground pipeline repair device includes a car body 1 on which a cleaning mechanism 2 is arranged.

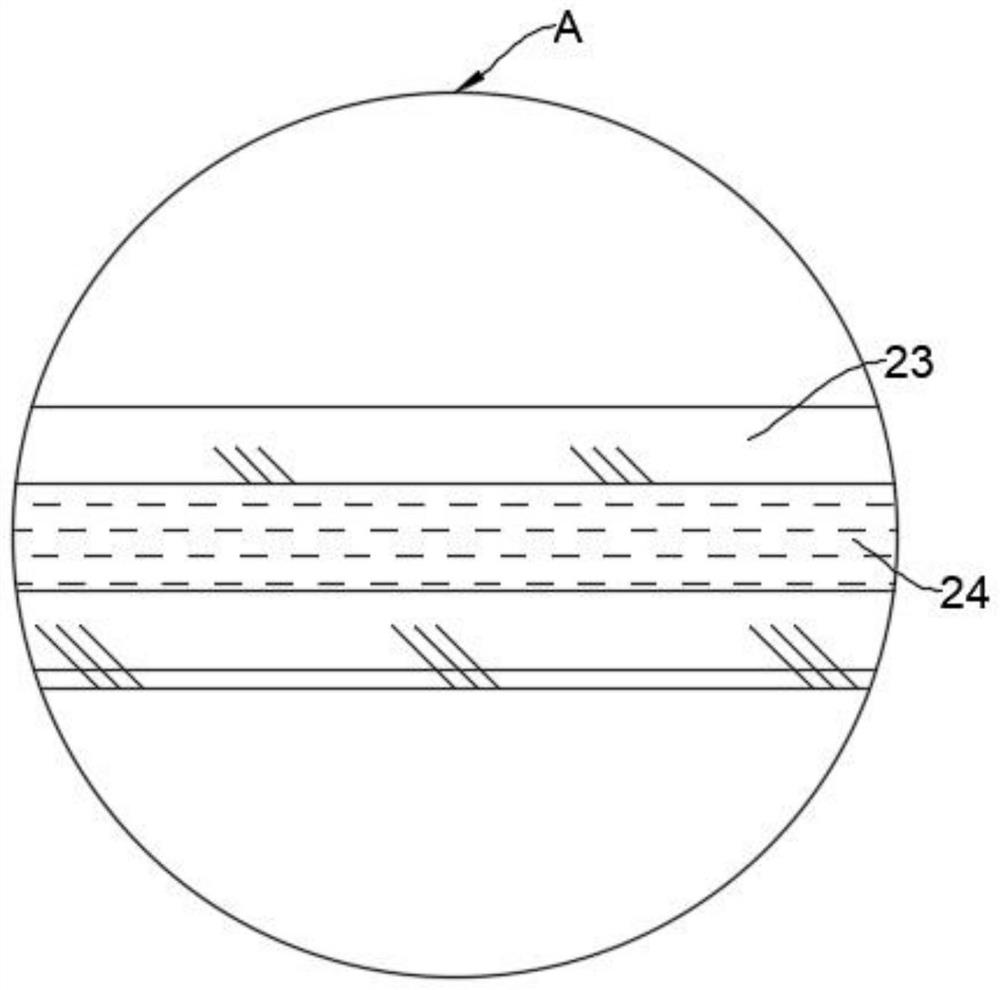

[0025] Such as figure 1 , Figure 6 As shown, the cleaning mechanism 2 is composed of a cleaning member 21 , a transmission shaft 22 and a receiving sleeve 23 .

[0026] Such as figure 1 As shown, the receiving sleeve 23 is fixedly connected to the car body 1, the second motor 12 is fixedly connected in the car body 1, the output end of the second motor 12 is fixedly connected to the transmission shaft 22, and the cleaning parts 21 are provided with multiple and fixed It is connected to the end of the transmission shaft 22 away from the second motor 12 .

[0027] When the second motor 12 works, the second motor 12 will drive the transmission shaft 22 fixedly connected with it to rotate, and the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com