Surface anti-corrosion treatment process for 45-degree handle-free door plate

A kind of anti-corrosion treatment, handle-free technology, applied in the direction of the surface coating liquid device, coating, etc., can solve the problems of cracking of anti-corrosion layer, long-term effective protection of difficult door panels, deterioration of anti-corrosion effect, etc., and achieve good elastic buffer performance. , prolong the anti-corrosion effect and slow down the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

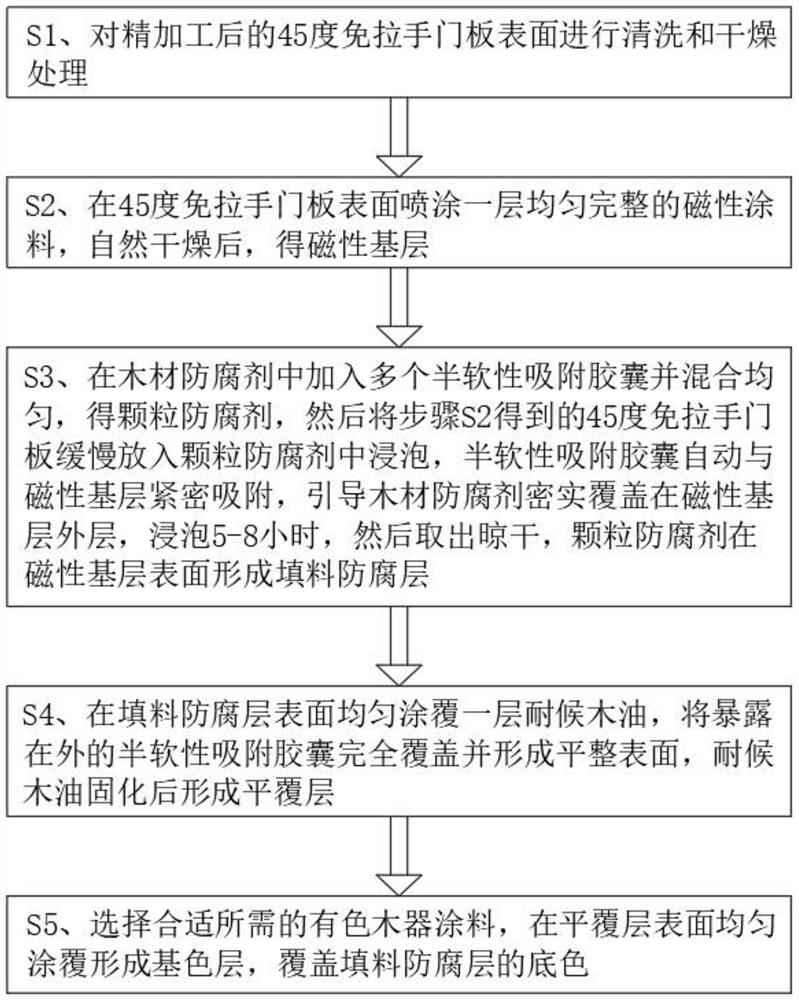

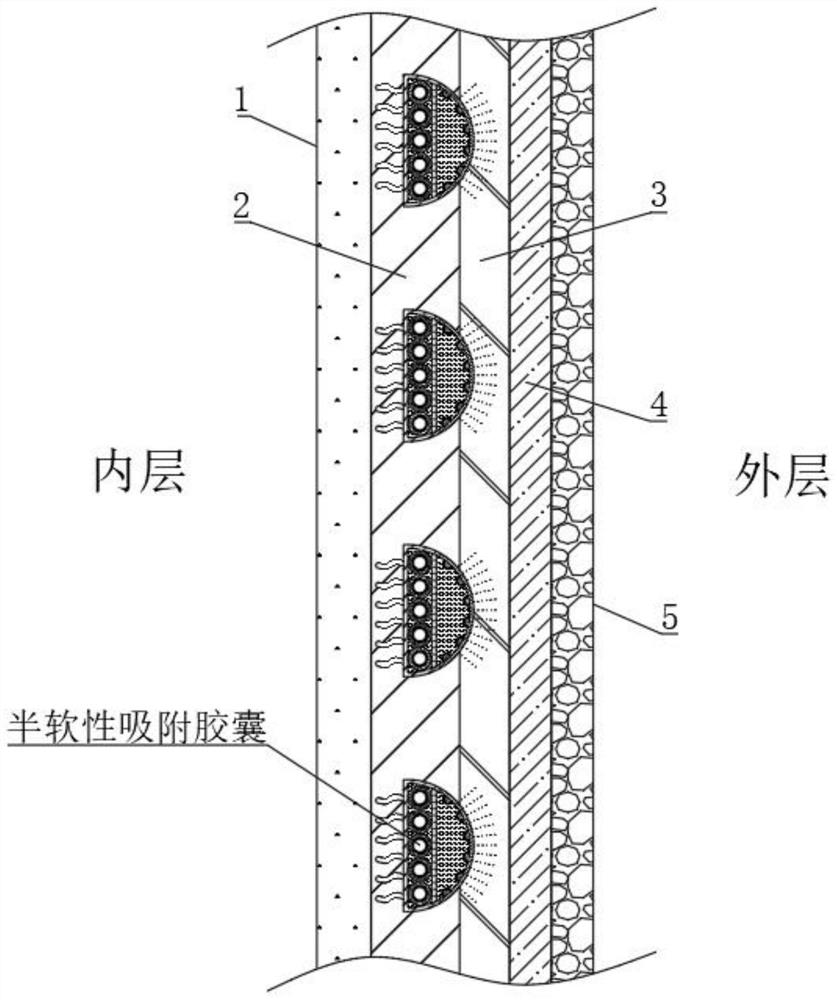

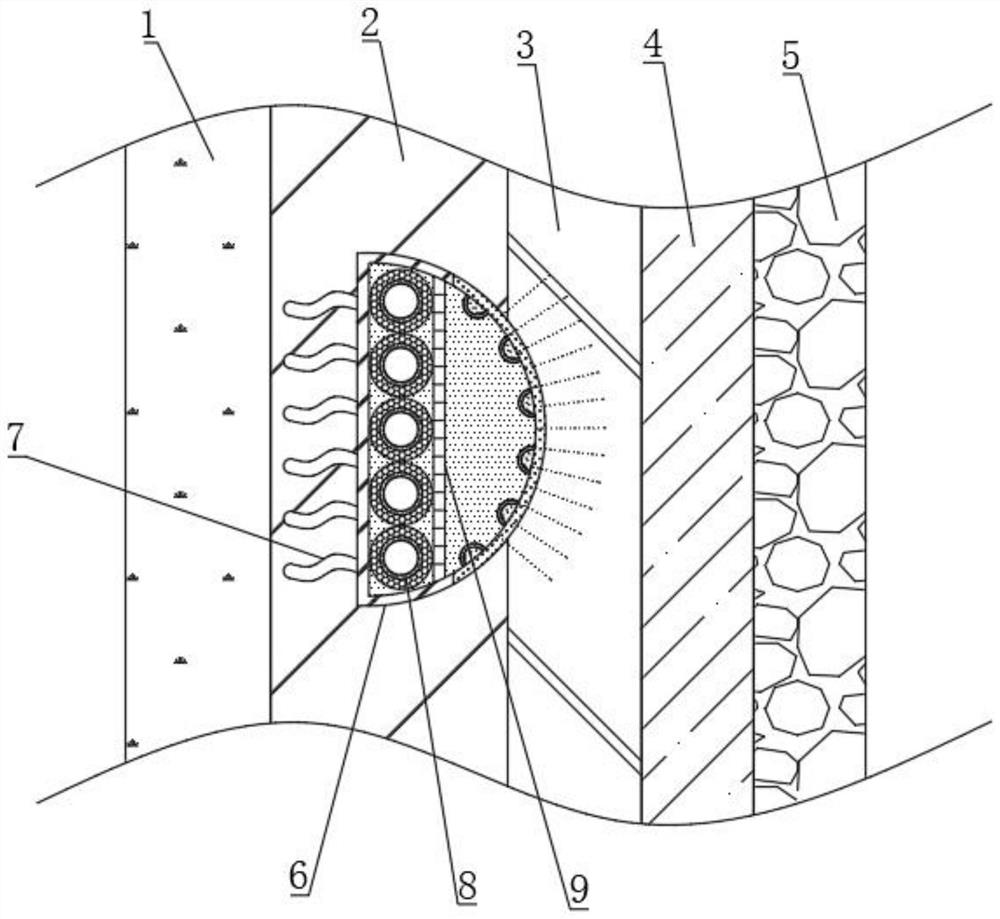

[0045] see figure 1 and figure 2 , a 45-degree handle-free door panel surface anti-corrosion treatment process, including the following steps:

[0046] S1. Clean and dry the surface of the 45-degree handle-free door panel after finishing to make the surface clean and free of dust and impurities;

[0047] S2. Spray a layer of uniform and complete magnetic paint on the surface of the 45-degree handle-free door panel, and after natural drying, the magnetic base layer 1 is obtained;

[0048] S3. Add a plurality of semi-soft adsorption capsules to the wood preservative and mix them evenly to obtain granular preservatives, and then slowly put the 45-degree handle-free door panel obtained in step S2 into the granular preservatives for soaking, and the semi-soft adsorption capsules automatically Adsorb closely with the magnetic base layer 1, guide the wood preservative to cover the outer layer of the magnetic base layer 1 densely, soak for 6 hours, and then take it out to dry, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com