Multi-focus child glasses processing device

A processing device and multi-focus technology, which is applied in the direction of grinding drive device, metal processing equipment, lens, etc., can solve the problems of easy wear of the lens, large difference in clamping strength, and affecting the efficiency of grinding, so as not to slip off and improve Convenience, the effect of reducing the chance of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

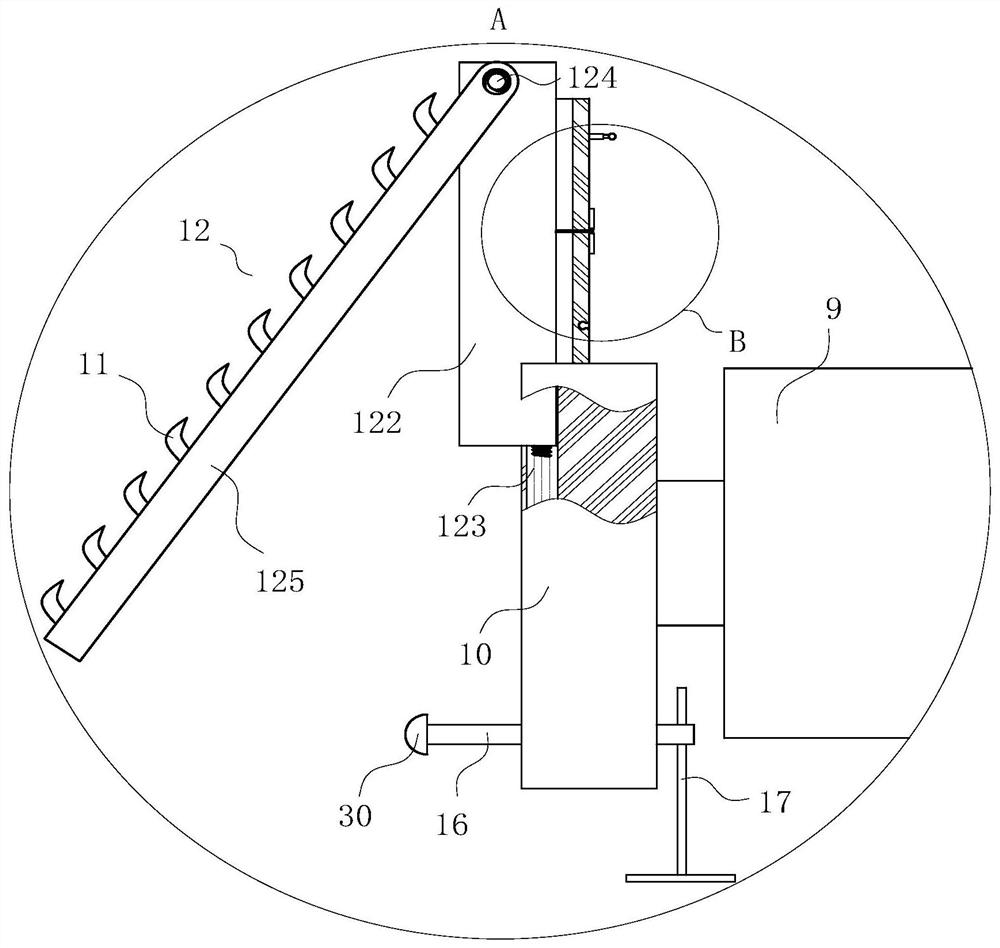

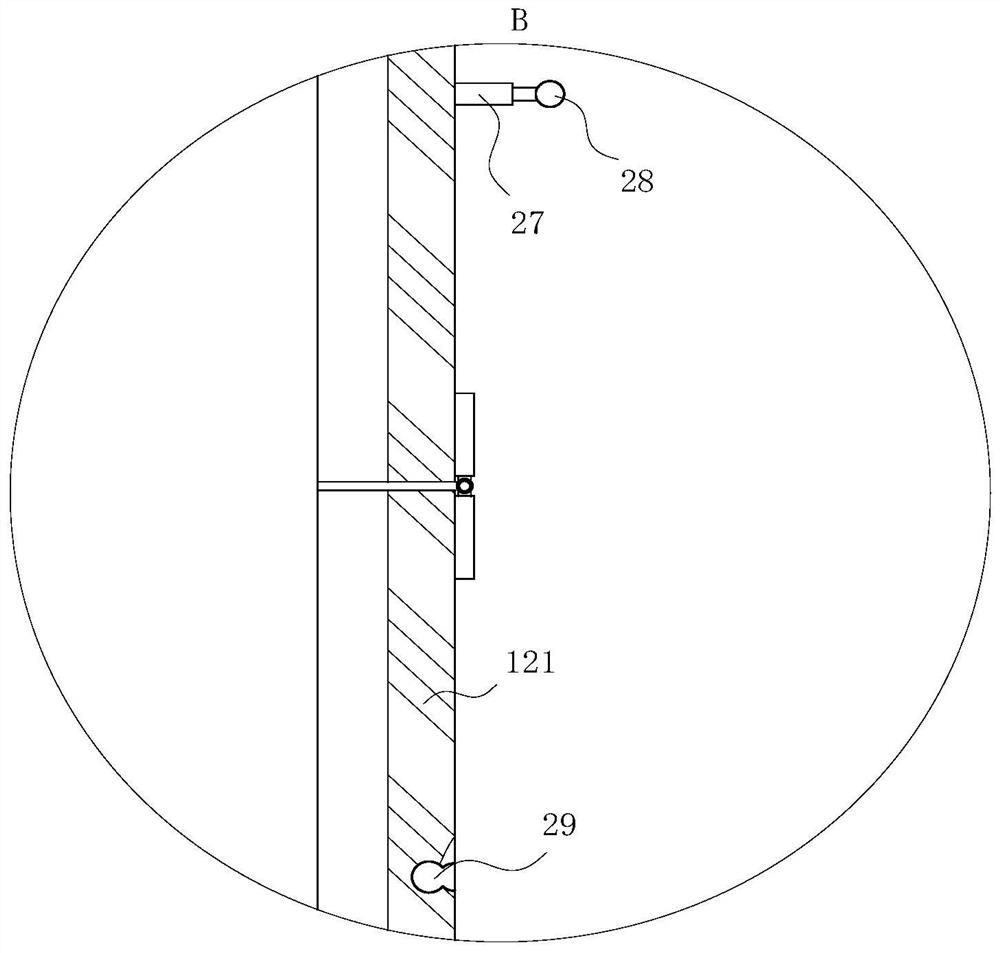

[0033] As a specific embodiment of the present invention, the limit card slot 121 includes a plurality of sub-slots 18, a hinge is arranged between two adjacent sub-slots 18, and the plurality of sub-slots 18 are in sequential contact with each other in the vertical direction. , and the bottom of the slot 18 is provided with a horizontal slot 19 and a vertical slot 20, the horizontal slot 19 communicates with the vertical slot 20, one end of the horizontal slot 19 is located on the inner side of the slot 18, and the bottom end of the vertical slot 20 is located at the bottom of the slot 18 On the bottom groove wall, a horizontal plate 21 is provided in the horizontal groove 19, and a vertical plate 22 is inserted on the horizontal plate 21. The vertical plate 22 is positioned in the vertical groove 20, and the top of the horizontal plate 21 is provided with a triangular groove 23, and The inside of the straight plate 22 is provided with a triangular plate 24, one end of the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com