Manufacturing and using method of anti-overflow mold for silica gel encapsulation

A technology of anti-overflow and silicone gel, which is applied in the field of anti-overflow mold production, can solve the problems of large size error of potting body, large error of plate material thickness, viscous glue, etc., so as to solve the problem of sealing and overflow , saving production costs, making simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the accompanying drawings and examples, and the protection scope of the present invention cannot be limited by this. The purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

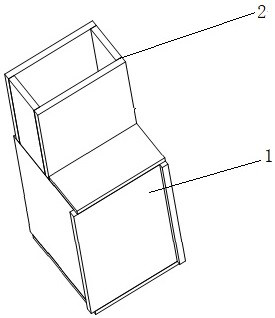

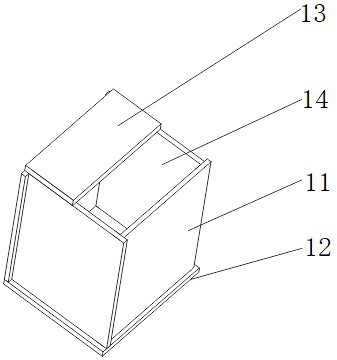

[0027] combined with Figure 1-3 A method for making and using an anti-spill mold for silicone gel potting, taking the production of a potting body with a length×width×height of 50mm×50mm×60mm as an example, the specific steps are:

[0028] Step 1: According to the required length and width of the potting body, select a hexahedron forming mold tooling with a length × width of 50mm × 50mm and unlimited height; select a transparent acrylic sheet of non-metallic material as the forming mold 1 and the overflow prevention mold 2's crafting materials.

[0029] Step 2: Making the forming mold 1: According to the required height of the potting body, select f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com