Non-woven fabric shunt winding and cutting device

A non-woven fabric cutting technology, which is applied in the cutting of textile materials, textiles and papermaking, fabric surface trimming, etc., can solve the problem that the cutting distance cannot be adjusted, achieve a good tension state, reduce looseness, and improve versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

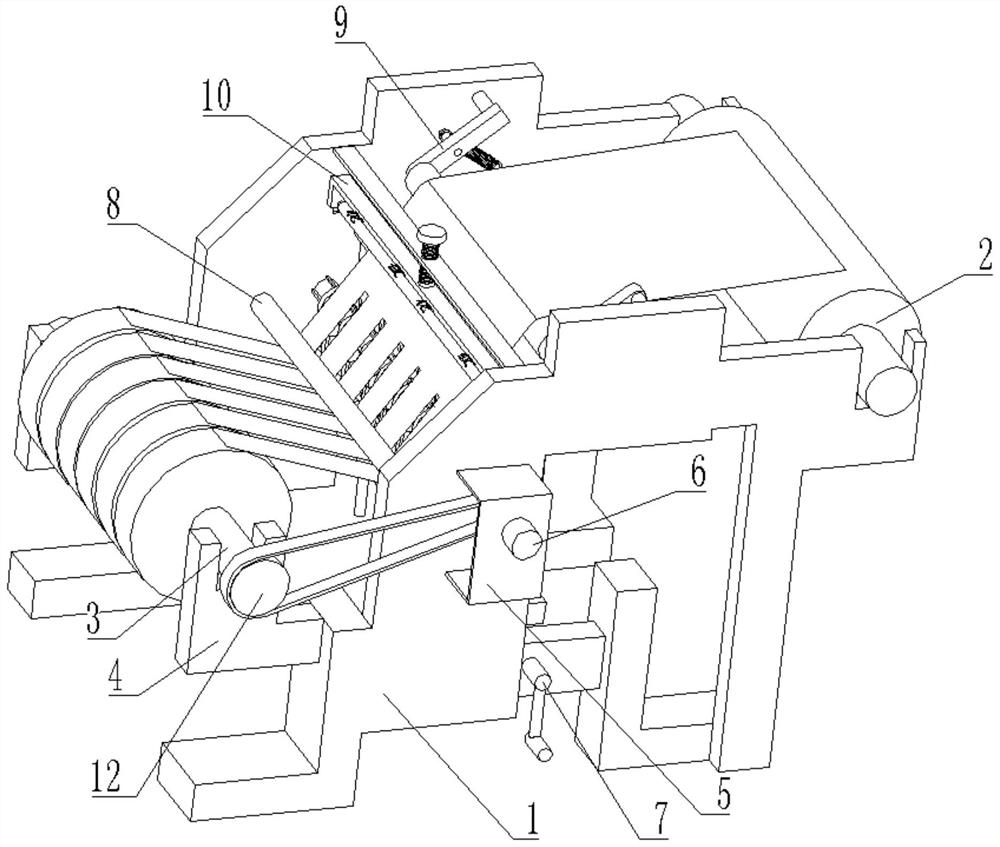

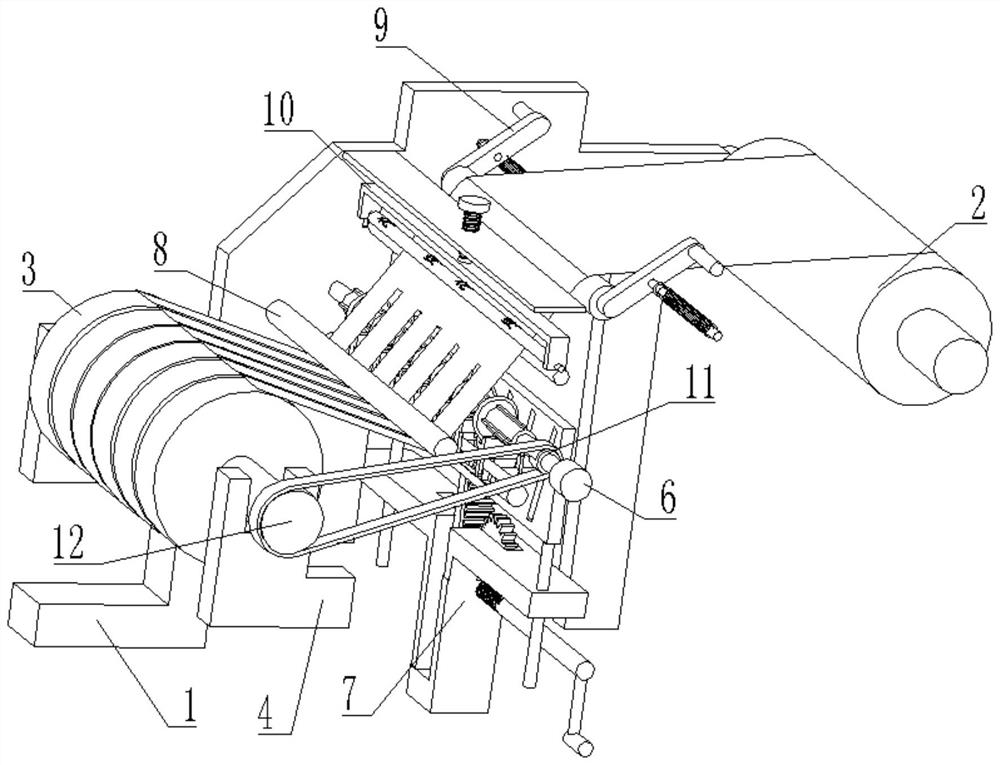

[0031] see Figure 1-5 , a non-woven roll cutting device, comprising a frame 1, the left side of the frame 1 is welded with a support plate 4, the upper surface of the support plate 4 is movably connected with an input roller 3, and the upper surface of the frame 1 is movable The output roller 2 is connected, the front part of the frame 1 is connected with the organic case 5 by bolts, the front part of the case 5 is connected with the motor 6 by bolts, and the inside of the frame 1 is respectively provided with an adjustment mechanism 7, an embossing mechanism 10 and a tensioning mechanism. The mechanism 9 and the tensioning mechanism 9 are located on the right side of the embossing mechanism 10 , the adjusting mechanism 7 is located below the embossing mechanism 10 , and the inner wall of the frame 1 is rotatably connected with a pressing roller 8 .

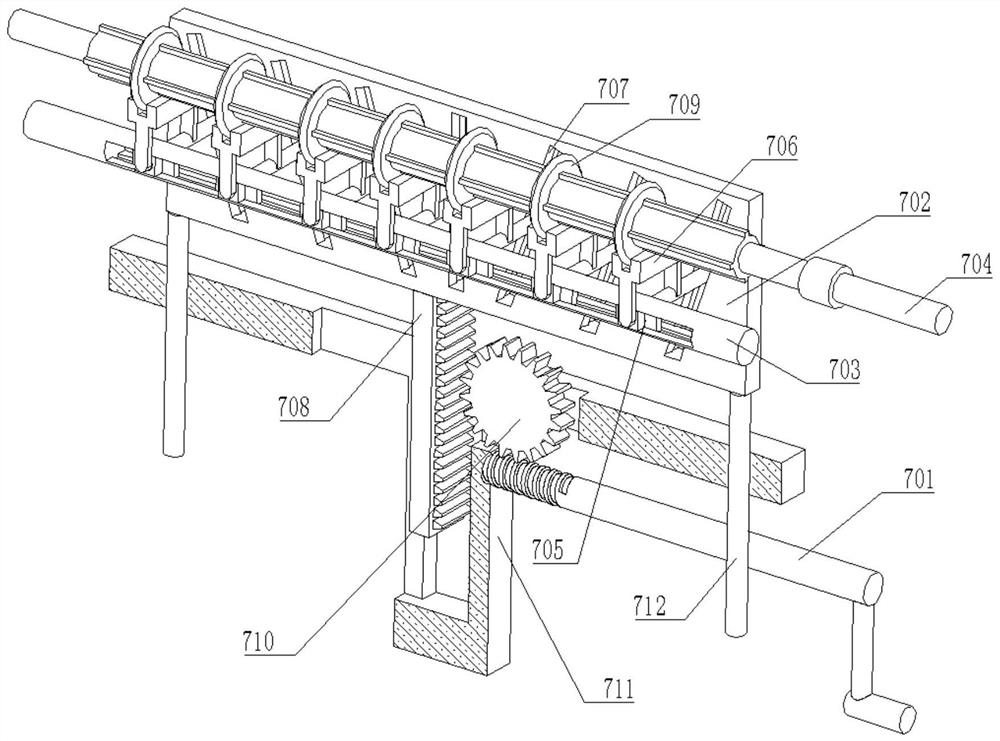

[0032] In this embodiment, the adjustment mechanism 7 includes an adjustment rod 701, the surface of the adjustment rod 701 is...

Embodiment 2

[0041] see Figure 6-7 On the basis of Embodiment 1, in this embodiment, the tensioning mechanism 9 includes a rotating bracket 91, the rear part of the rotating bracket 91 is rotatably connected with a tensioning roller 92, and the inside of the rotating bracket 91 is fixedly connected with a rotating shaft 93, The front end of the rotating shaft 93 is rotatably connected to the inner wall of the frame 1, the inner wall of the frame 1 and the front portion of the rotating bracket 91 are fixedly connected with a spring column 94, and a tension spring 95 is fixedly connected between the two spring columns 94, Through the action of two tension springs 95, the tension roller 92 is pushed up, so that the non-woven fabric is always close to the tension roller 92, so that the non-woven fabric can be well kept in tension during the process of conveying and cutting , to reduce looseness.

[0042] In this embodiment, there are two tension springs 95, and the two tension springs 95 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com