A Grading Method for Cold Recycled Mixture

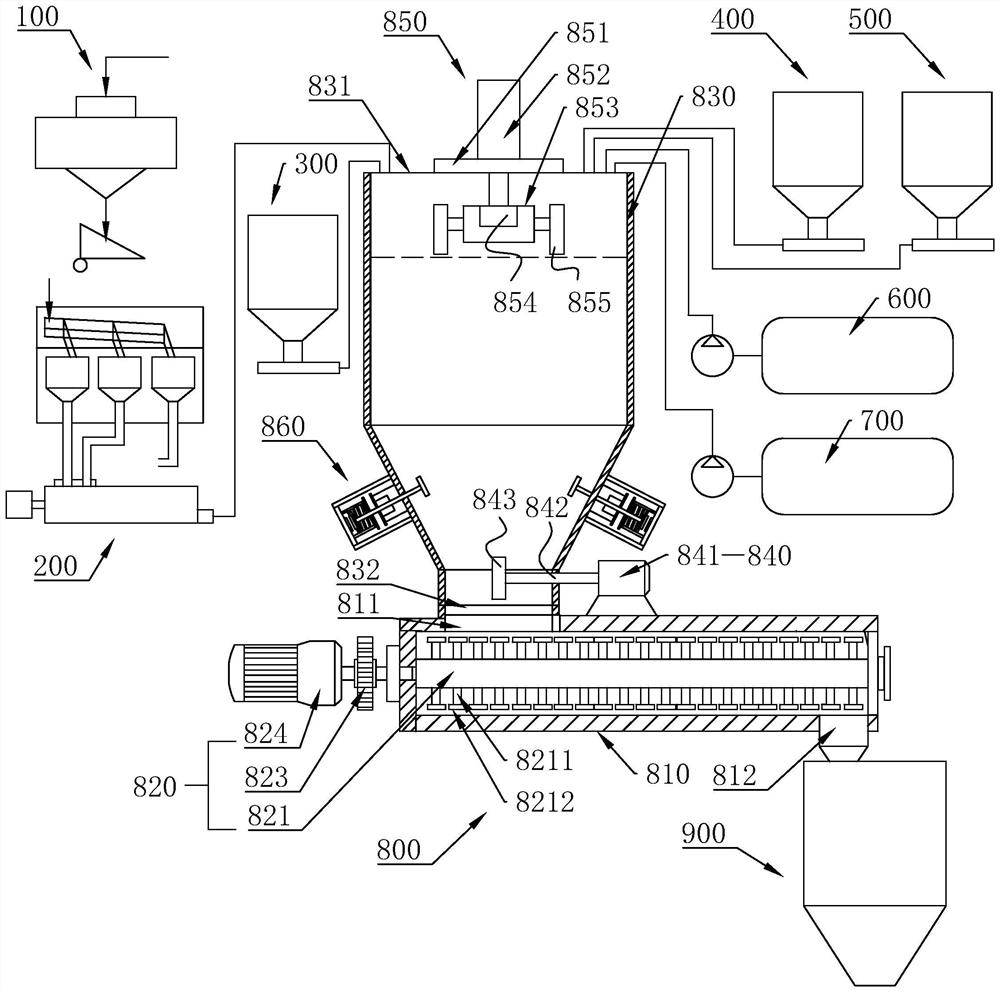

A technology of cold recycled mixture and grading, which is applied in roads, road repairs, construction, etc., can solve the problems of low strength, achieve the effect of improving strength, improving utilization rate, and realizing high-efficiency work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

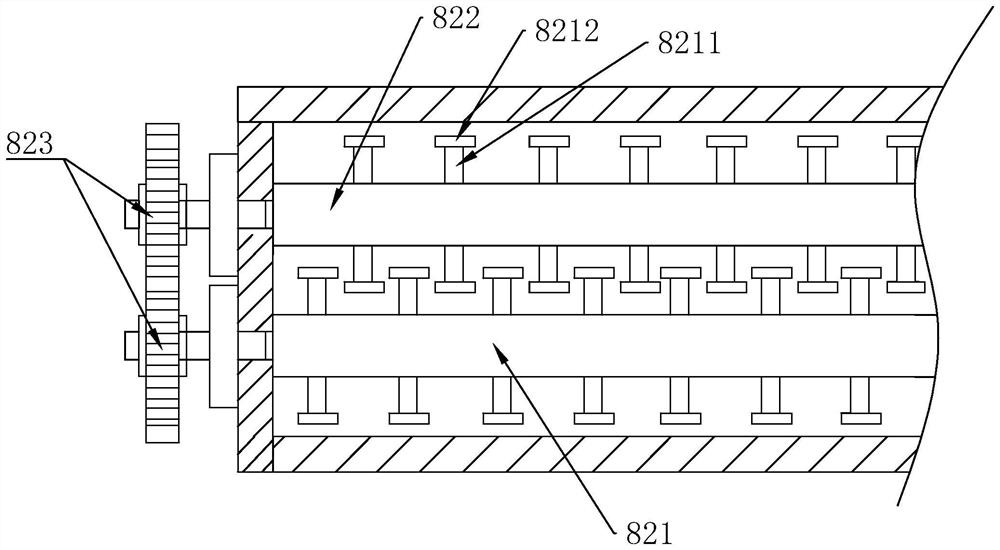

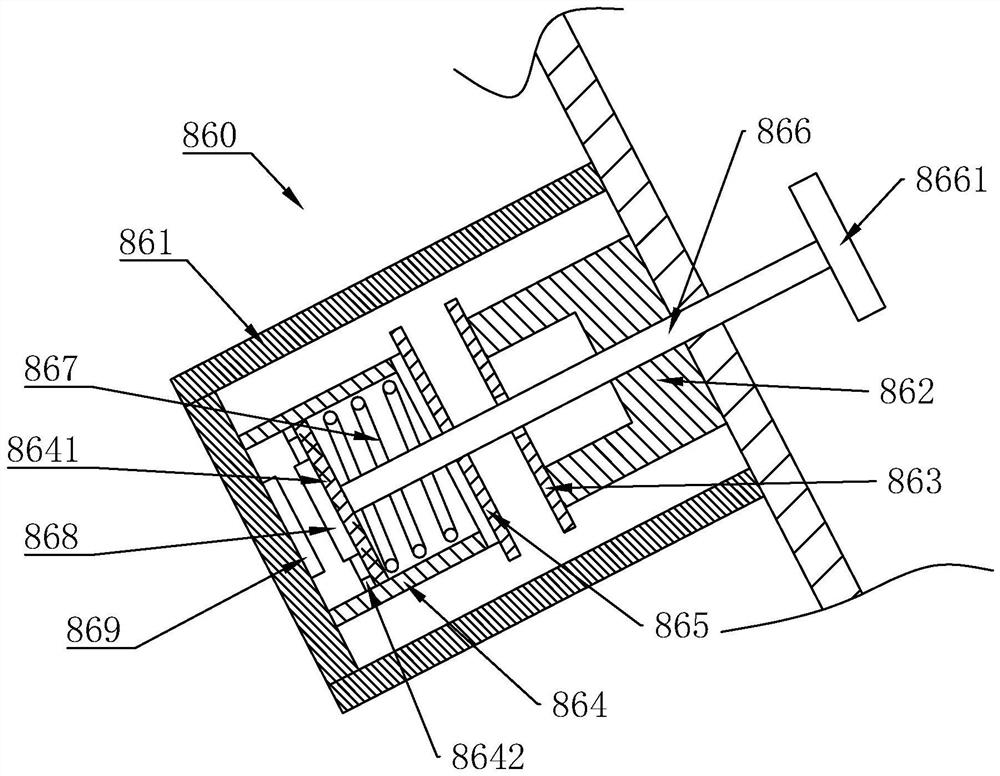

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: A method for grading cold recycled mixtures, wherein the cold recycled mixtures include: 16 parts of basalt stones with a particle size of 20mm-30mm, 50 parts of road milling with a particle size of 0-10mm, granules 30 parts of road milling with a diameter of 10mm-30mm, 2 parts of cement, 2 parts of mineral powder, 3.5 parts of emulsified asphalt, and 3-5 parts of water. The above materials are mixed for asphalt mixture grading, and geotechnical impact tests are carried out for different water contents. The tests are as follows:

[0049] test count Moisture content (%) Maximum dry density (g / cm 3 )

[0050] It can be seen from the above that the optimal water content of the molded cold recycled specimen is 3.8%, and the corresponding maximum dry density is 2.287g / cm 3 .

Embodiment 2

[0051] Embodiment 2: A method for grading cold recycled mixtures, wherein the cold recycled mixtures include: 16 parts of basalt stones with a particle size of 20mm-30mm, 50 parts of road milling with a particle size of 0-10mm, granules 30 parts of road milling with a diameter of 10mm-30mm, 2 parts of cement, 2 parts of mineral powder, 2.5-4.5 parts of emulsified asphalt, and 3.8 parts of water. Mix the above materials for asphalt mixture grading, and conduct splitting experiments for different amounts of emulsified asphalt. The test is as follows:

[0052] test count Amount of emulsified asphalt (%) Dry splitting strength (MPa) Wet splitting strength (MPa) 1 2.5 0.66 0.61 2 3 0.75 0.67 3 3.5 0.76 0.68 4 4 0.72 0.62 5 4.5 0.68 0.63

[0053] It can be seen from the above that the maximum dry splitting strength can be obtained when the mass fraction of the optimum emulsified asphalt is 3.5 phr in the molded cold recycled spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com