A vertical long cantilever truss structure for spiral ascending curtain wall support and its application

A truss structure and cantilever technology, which is applied to walls, building components, building structures, etc., can solve problems such as complex joint connection structure, complex mechanical performance of the system, and complex assembly of components, achieving clear force transmission, high rigidity, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

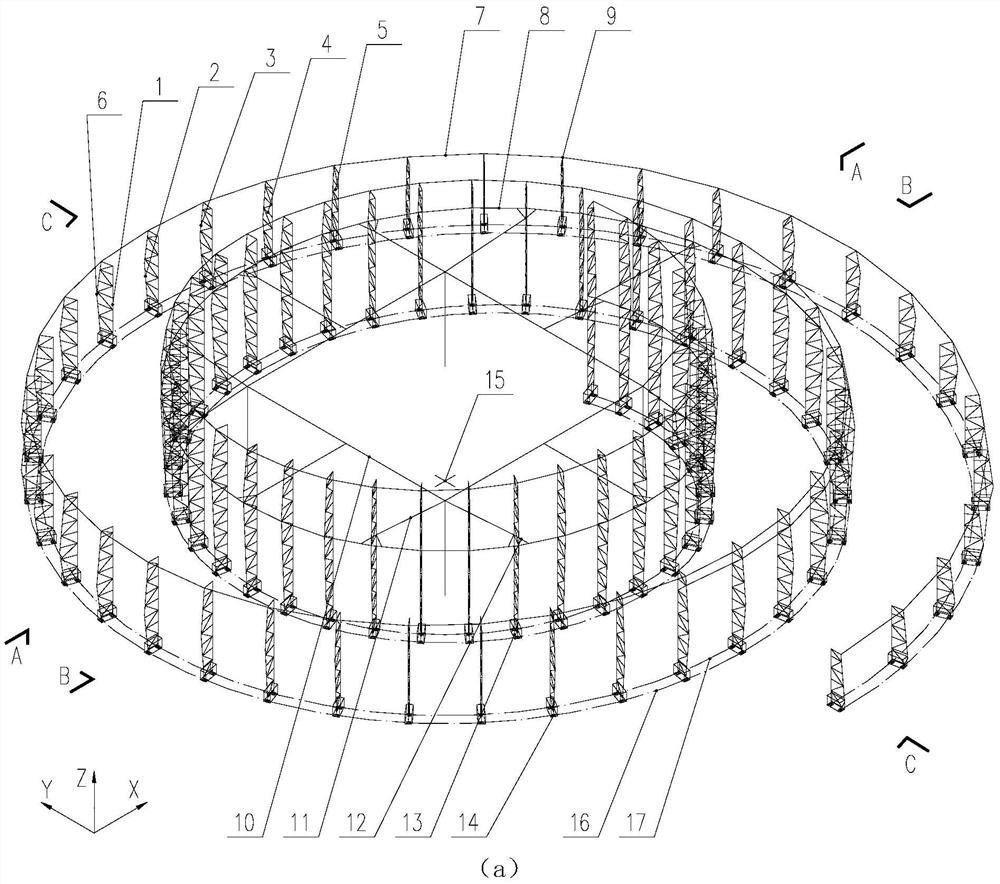

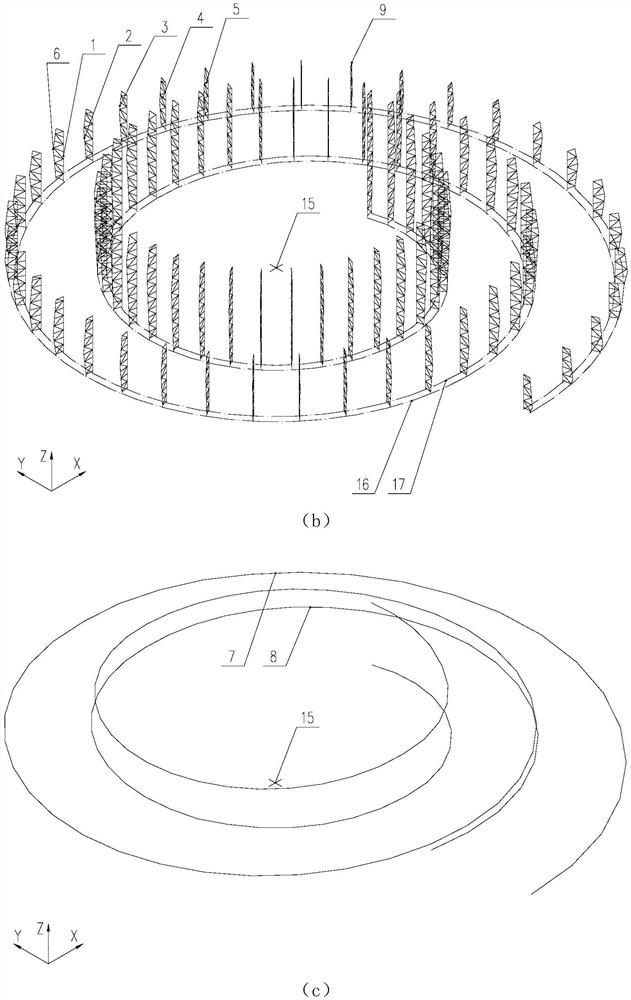

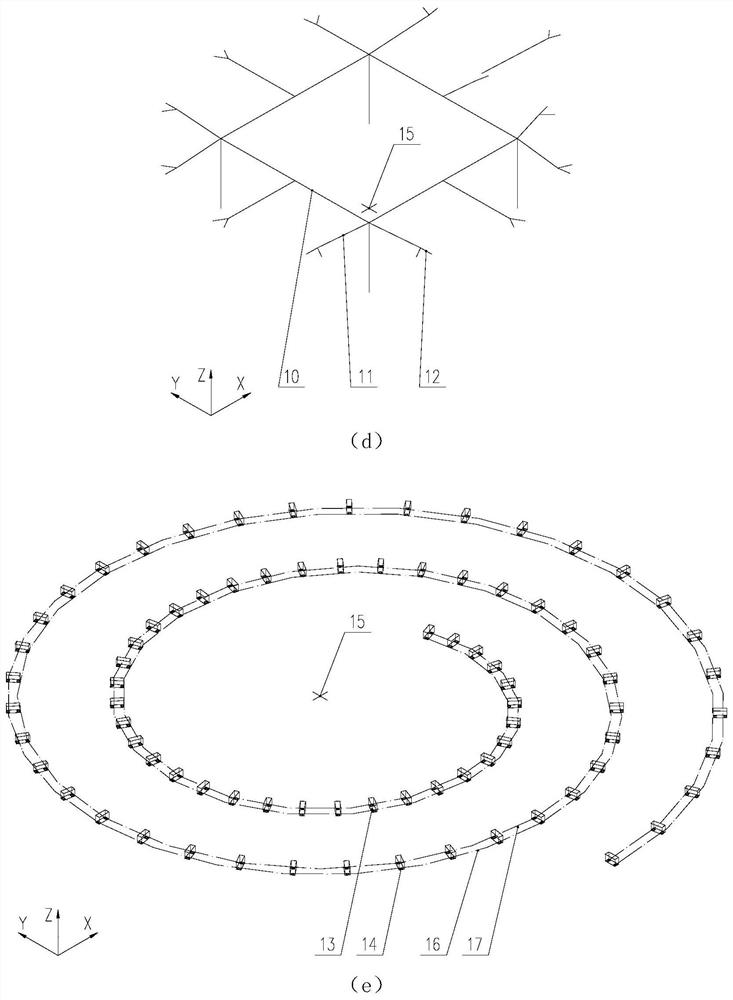

[0048] Such as figure 1 a-1e and Figure 2-Figure 4 As shown, the vertical long cantilever truss structure used for the support of the spiral ascending curtain wall includes a vertical long cantilever truss, a ring connecting steel beam, a lateral support structure, and a bottom rigid support. The vertical long cantilever truss ( figure 1 b) Consists of a series of single vertical long cantilevered trusses arranged in a multi-circle spiral, adopting the grid structure of planar tube trusses, and the top elevation of the vertical long cantilevered trusses are arranged according to spiral ascending gradients, forming a vertical anti-lateral force support core structure; the hoop connecting steel beams ( figure 1 c) It consists of two hoop-connected steel beams located at the top of all vertical long cantilever trusses and the middle of the superelevation vertical long cantilever trusses in the inner circle. The steel beam connection setting at the middle elevation position be...

Embodiment 2

[0063] Such as Figure 9 As shown, the specific component assembly process of the vertical long cantilever truss structure used for spiral ascending curtain wall support is as follows:

[0064] (1) The vertical main chord 1 of the vertical long cantilever truss, the first inclined main chord of the lower section, the second main chord of the upper section 3, the horizontal branch of the vertical long cantilever truss 4, the vertical long overhang The oblique branch tubes 5 of the cantilever truss form the basic unit of a single vertical long cantilever truss in the form of a "single oblique bar" planar tube truss; knuckle point 6;

[0065] (2) The single vertical long cantilever truss is arranged along the normal direction of the vertical curtain wall surface, with the central positioning point 15 as the center of the spiral, and multiple vertical long cantilever trusses are arranged to form a vertical long cantilever with multi-turn spiral arrangement In the truss structure...

Embodiment 3

[0072] This patent also provides an application of a vertical long cantilever truss structure supported by a spiral ascending curtain wall in the design and bearing of a steel structure frame system supported by a vertical superhigh cantilever curtain wall supported by multi-circle spiral ascending arrangements on the roof. The above-mentioned vertical long cantilever refers to a vertical long cantilever truss with a vertical single cantilever height not less than 10 meters.

[0073] Compared with the deficiencies of the prior art, the vertical long cantilever truss structure provided by the present invention for spiral ascending curtain wall support is based on the central support frame combining the vertical long cantilever The support structure provides middle support for the super-high truss, and forms a single-cantilever vertical truss form through rigid supports, which can realize the shape and function of vertical super-high cantilevered curtain walls and curved building...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com