Steel structure metal profiled plate roof leakage on-site detection device

A technology of metal profiling and on-site inspection, applied to measuring devices, roofs, roof coverings, etc., can solve the problems of large friction loss of the shell, increase of equipment running resistance, repeated inspections, etc., to avoid friction loss and reduce work burden , Keep the effect of equipment balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

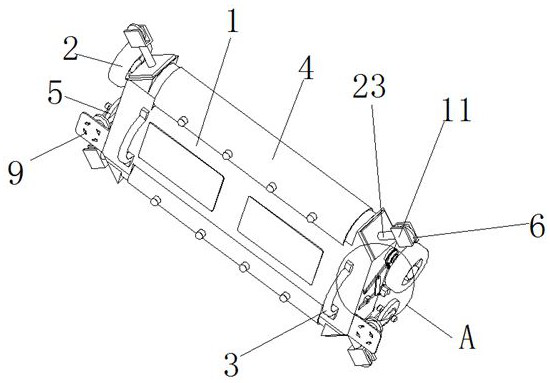

Embodiment 1

[0032] Embodiment 1 introduces an on-site detection device for steel structure metal profiled roof leakage. The invention can realize the rotation of the equipment at any angle by setting the universal wheel 5, and does not require the measurer to move the equipment to the target direction, which is convenient for operation. It can also reduce the workload of the operator; by setting the protective wheel 6, the protective wheel 6 is in direct contact with the wall and has a small rolling friction with the wall. When the equipment is turned against the wall for a short time, the protective wheel 6 has a guide The role is to coordinate the universal wheel 5 to turn; when the equipment needs to keep walking against the wall when measuring the contact between the roof and the wall, the protective wheel 6 can not only maintain the balance of the equipment, but also avoid the direct contact between the device shell 1 and the wall. Friction loss. details as follows:

[0033] A kind ...

Embodiment 2

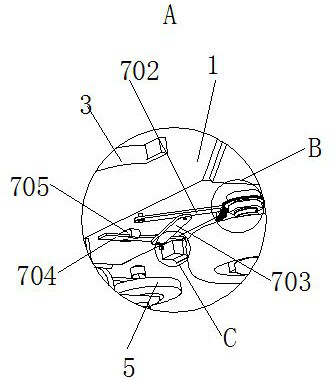

[0037] Embodiment 2 is an improvement on the basis of Embodiment 1. The main improvement is reflected in the addition of a marker component 8 and a marker connection component 7, wherein when the marker component 8 and the marker connector component 7 work together, a dotted line can be marked on the boundary of the detection area , which is convenient for the operator to determine a new detection area after turning, to ensure that there will be no missed inspection or repeated inspection. By setting the driving wheel 701 on the roller shaft 10, when the equipment is suspended, the marking sponge brush 802 will immediately No ink will be wasted when the work is stopped. In addition, the driving wheel 701 is sleeved on the roller shaft 10 and the adjacent mark traces are distributed at equal intervals, which has nothing to do with the operating speed of the equipment. The specific improvements are as follows:

[0038] A kind of on-the-spot detection device for steel structure m...

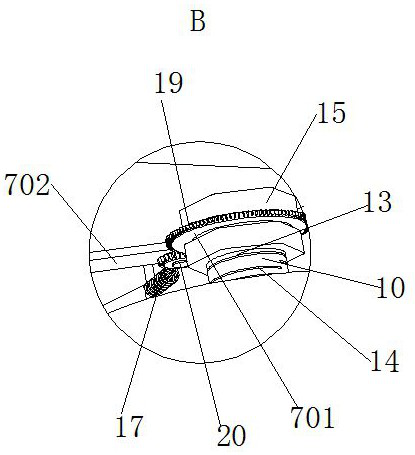

Embodiment 3

[0044] Embodiment 3 is an improvement on the basis of Embodiment 4. The main improvement is reflected in the addition of the roller 2 and the tooth plate 19, which can avoid the sliding loss caused by the direct contact between the driving wheel 701 and the first rotating rod 702. The first thread 12, the second thread 13 and the third thread 14, together with a pair of nuts 15 and a backing plate, can realize the adjustment of the drive runner 701 to the state where it does not engage with the roller 2, and at this time, the equipment will not Marking is suitable for detection occasions that are not suitable for marking. details as follows.

[0045] A kind of on-the-spot detection device for steel structure metal profiled roof leakage, such as Figure 1-9 As shown, the detection device includes a device housing 1, a roller 2, a handle 3 and a flexible electrode 4, and the detection device includes a universal wheel 5, a protective wheel 6, a marker connection component 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com