Residual oil dispersion degree characterization method

A dispersion degree and remaining oil technology, which is applied in earthwork drilling, special data processing applications, wellbore/well components, etc., can solve problems such as the lack of characterization methods for remaining oil dispersion degree, so as to improve the scope of application, ensure versatility, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

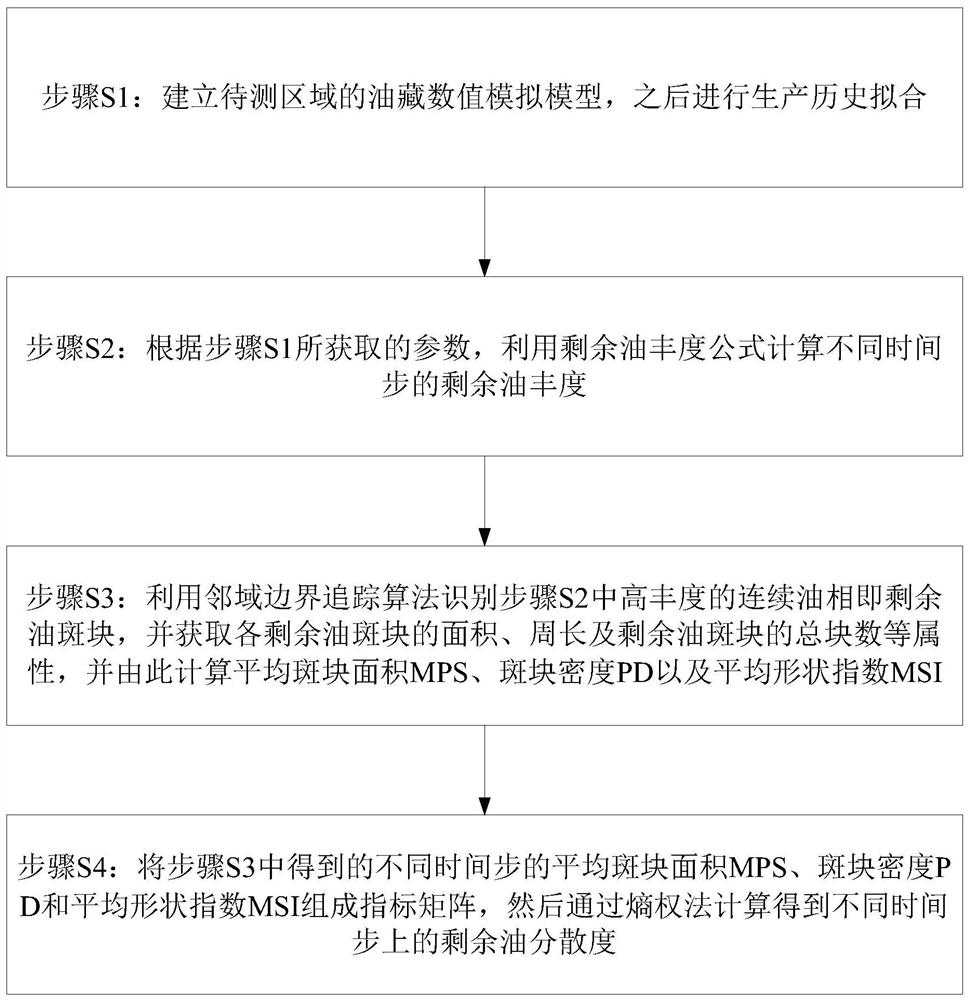

[0060] Such as Figure 2 to Figure 9 As shown, implement step S1: establish the numerical simulation model of the reservoir in the area to be tested, where Table 1 shows the specific parameters of the numerical simulation model of the reservoir.

[0061]

[0062] Table 1

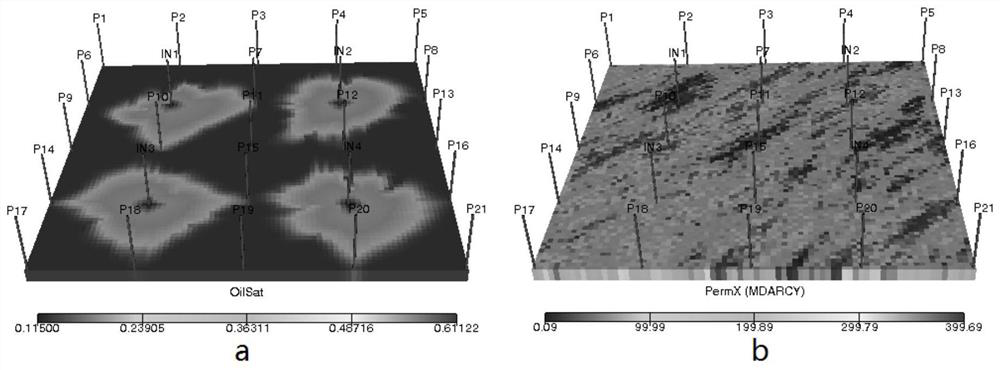

[0063] Such as figure 2 Shown is the reservoir numerical simulation model of the area to be tested, where a represents the distribution of oil wells, and b represents the heterogeneous distribution of permeability.

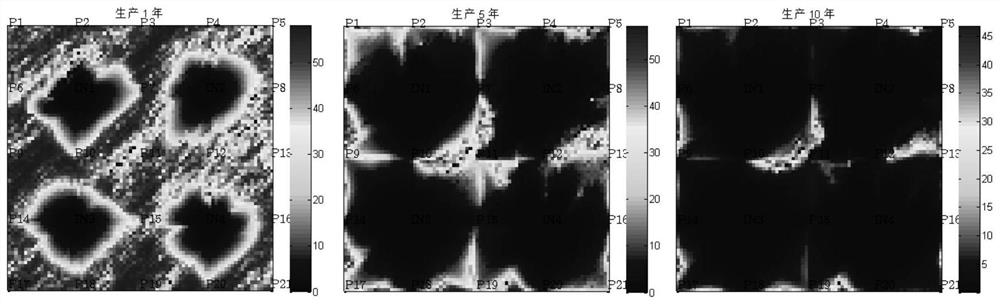

[0064] Such as image 3 As shown, implement step S2: according to the parameters obtained in step S1, use the remaining oil abundance formula to calculate the remaining oil abundance at different time steps, where, from left to right, they are 1 year of production, 5 years of production and 10 years of production remaining oil abundance.

[0065] Such as Figure 4 As shown, implement step S3: use the neighborhood boundary tracking algorithm to identify image 3 The high-abundance conti...

Embodiment 2

[0072] Such as Figure 10 to Figure 13 Shown is the characterization of remaining oil dispersion of the reservoir numerical simulation model in the area to be tested.

[0073] Such as Figure 10 As shown, the area to be tested is located at the southwest end of the oilfield, which is a semi-anticline structure cut by faults, and the terrain of the whole area is high in the north and low in the south. The structure of the area to be tested is relatively complete, and it belongs to a block with a relatively simple structure among complex fault blocks. The Mapengkou fault develops in the north, extending about 10km. The area to be tested contains four sand layers I, II, III and IV. The average porosity of the reservoir is 28%, which belongs to high porosity reservoir. The average effective permeability of the reservoir is 341mD, which belongs to medium-high permeability reservoir. The average surface crude oil density is 0.85-0.92g / cm 3 , the underground viscosity is 1.2-19.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com