Damping device for electromechanical equipment maintenance

A technology of shock absorbing devices and electromechanical equipment, which is applied in the direction of mechanical equipment, manual conveying devices, springs/shock absorbers, etc., can solve problems such as performance degradation, easy wear, and shock absorbing devices that cannot be fixed by electromechanical equipment, so as to avoid offset Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

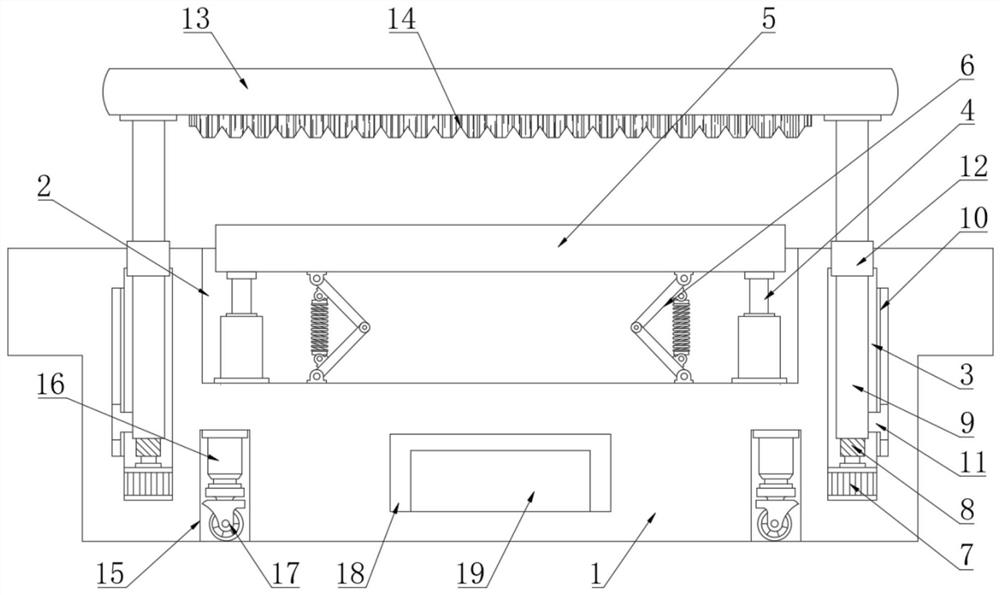

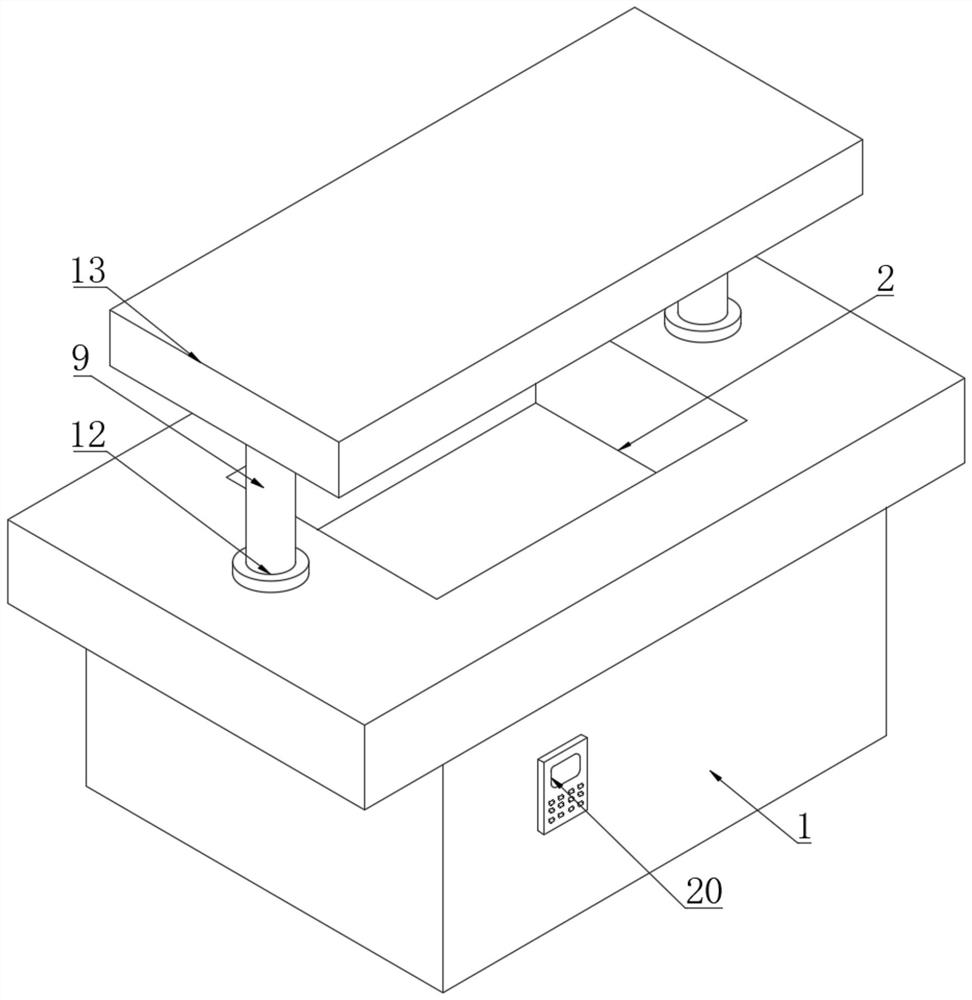

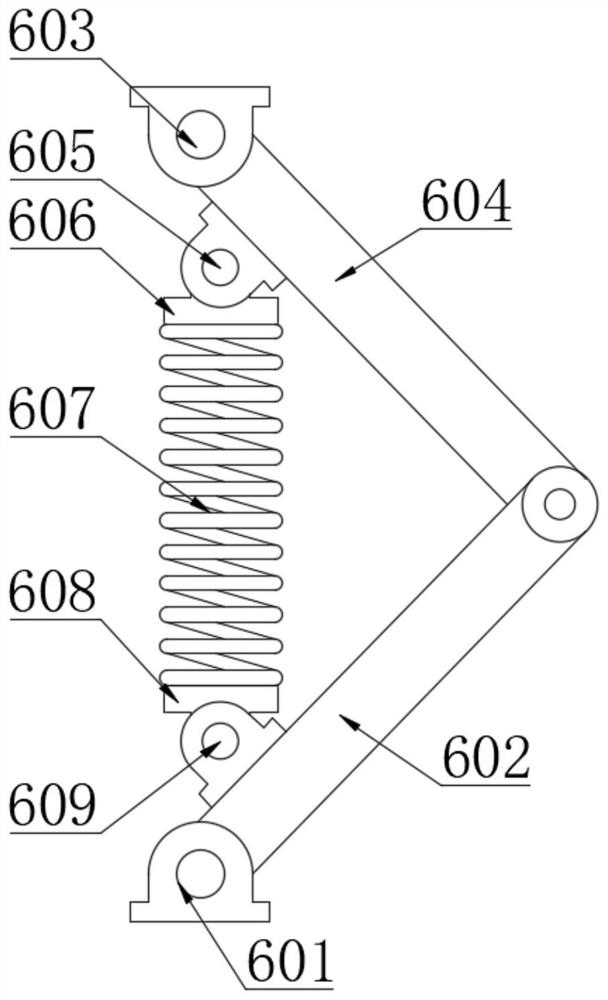

[0019] see Figure 1-3 , the present invention provides a technical solution: a shock absorbing device for electromechanical equipment maintenance, including a fixed platform 1, a shock absorber 2 is provided inside the fixed platform 1, and a damper 4 is fixedly connected to the inside of the shock absorber 2. The top of the device 4 is fixedly connected with a placement plate 5, the interior of the shock absorber 2 is fixedly connected with a shock absorber 6, the top of the shock absorber 6 is fixedly connected with the lower surface of the placement plate 5, and the inside of the fixed table 1 is provided with an adjustment chamber 3. The interior of the adjustment chamber 3 is fixedly connected with the positive and negative motor 7. By setting the positive and negative motor 7, when the staff uses the device to transport the electromechanical equipment, the staff only needs to start the positive and negative motor 7 through the control switch 20 , under the cooperation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com