Aero-engine blade defect detection method based on convolutional neural network

A convolutional neural network and aero-engine technology, applied in the field of defect detection, can solve the problems of sensitivity to light changes in the detection site, affecting the improvement space, and being susceptible to interference, etc., so as to improve the recall rate, improve the detection accuracy, and enhance the universality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

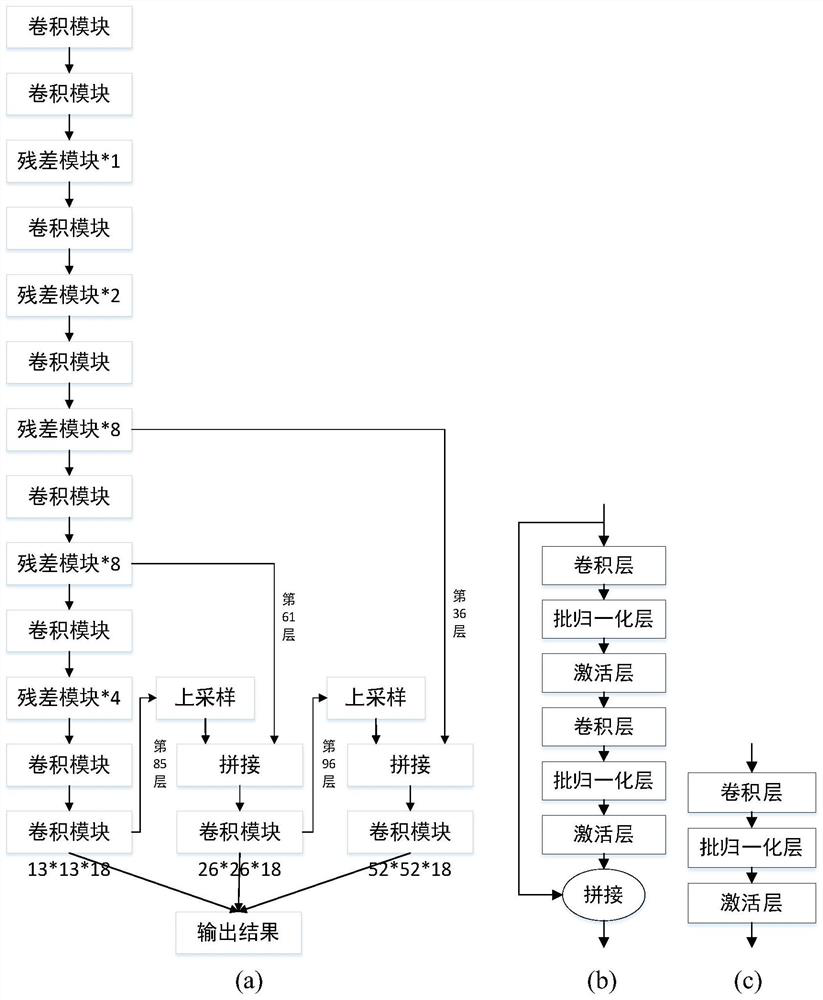

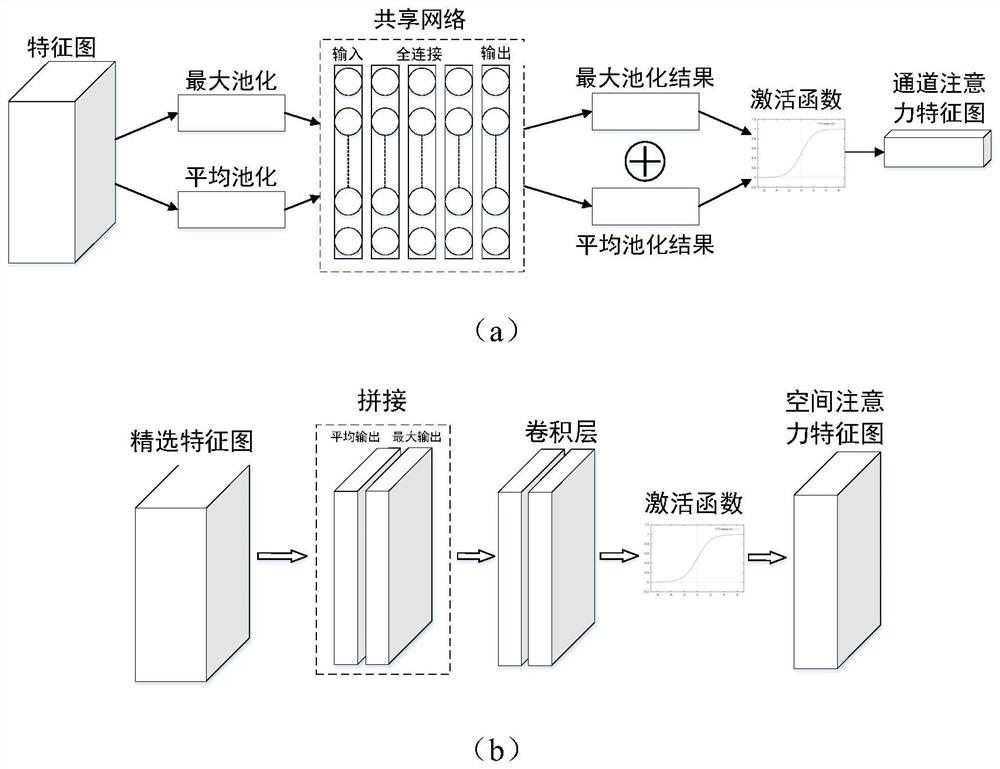

[0047] Theoretical research shows that the convolutional neural network is more inclined to areas with large pixel changes in the process of automatic feature extraction. Usually, shallow convolution kernels are used to detect low-level features, such as edges, corners, curves, etc., while deep convolutions The accumulation kernel can combine shallow low-level features, such as semicircles, quadrilaterals, etc. However, the layer-by-layer iterative operation of the network makes the model learn the outline information of the object and gradually ignore the texture details. Therefore, the perception ability of the detection model for texture details is bound to have a certain impact on the detection results.

[0048] In addition, the pre-experimental results show that the recall rate of the detection model is usually low, and the visual detection results show that the defect area cannot be effectively determined, the model usually cannot achieve normal detection or there are mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com