Explosion-proof combination valve, top cover and battery

A combined valve and top cover technology, which is applied in the direction of secondary batteries, battery pack components, secondary battery gas removal, etc., can solve the problems of inability to slow down or eliminate thermal runaway and single function, so as to slow down thermal runaway and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

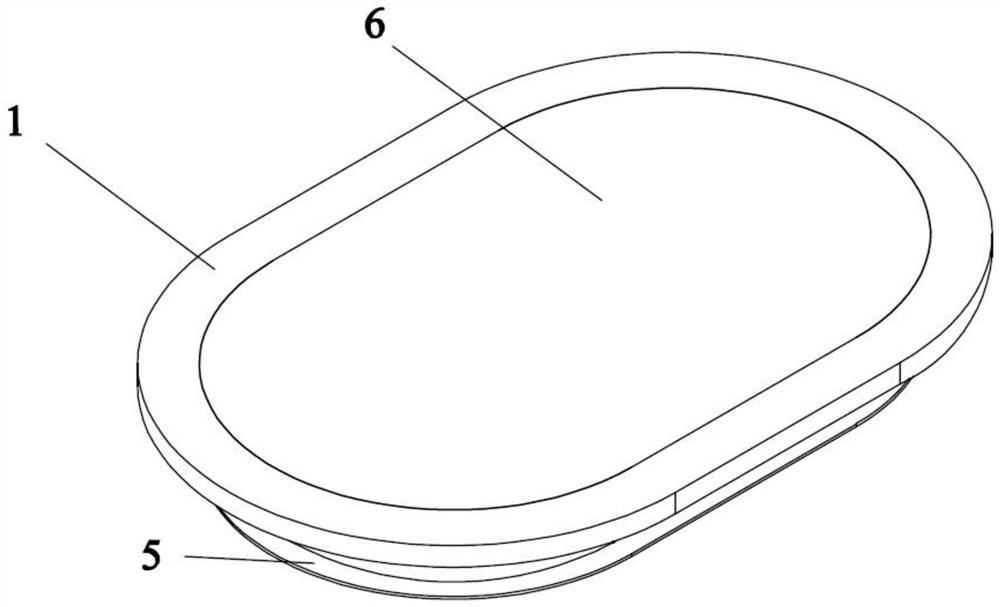

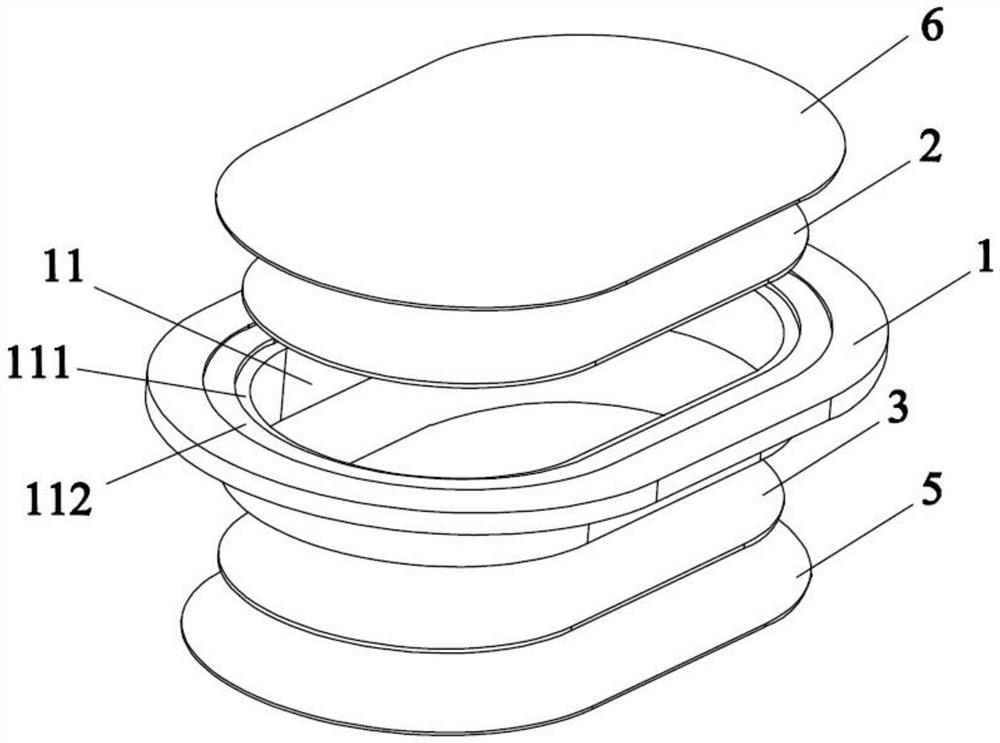

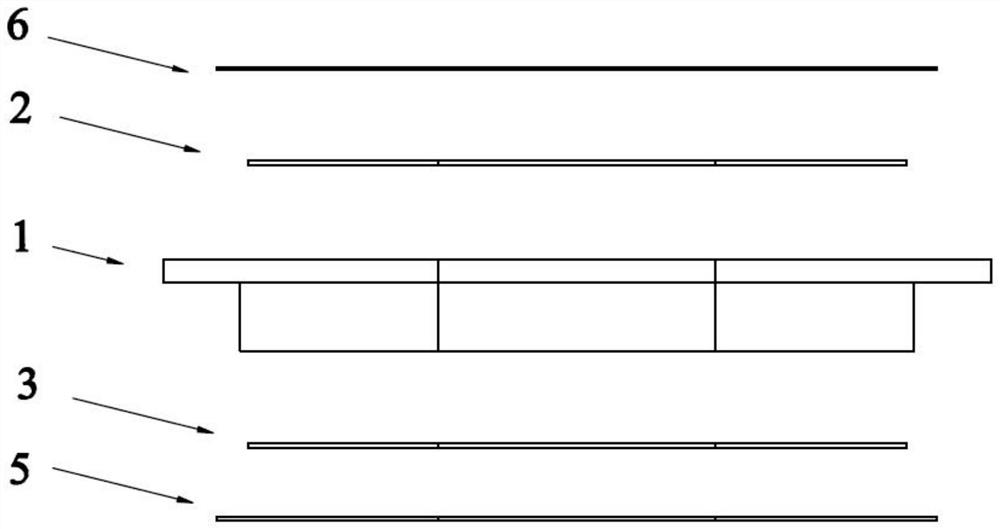

[0053] An explosion-proof combined valve, comprising an explosion-proof chamber 1, which is provided with a through hole 11; an outer explosion-proof plate 2, which is arranged above the through hole 11; an inner explosion-proof plate 3, which is arranged below the through hole 11; an explosion-proof chamber 1, an outer explosion-proof plate 2 and the inner explosion-proof plate 3 form a closed space for containing explosion-proof materials, the enclosed space contains explosion-proof materials, and the inner explosion-proof plate 3 ruptures under the set conditions to release the explosion-proof materials into the battery.

[0054] Because the existing explosion-proof valve has the following defects: it adopts a single-layer membrane structure, the explosion-proof structure is relatively simple and has a single function, and only one membrane covers the reserved hole; it can only exhaust in one direction, and cannot slow down or prevent the occurrence of thermal runaway. There...

Embodiment approach 2

[0065] see Figure 5 to Figure 8 As shown, the difference from the first embodiment is that the explosion-proof chamber 1 of this embodiment is provided with a breakthrough structure 4, which can pierce the inner explosion-proof plate 3 at a set temperature and / or pressure, and the breakthrough structure 4 includes a fixed frame and at least one punching knife 42 / punching needle, the fixed frame is installed in the explosion-proof chamber 1 / integrated with the explosion-proof chamber 1, the fixed frame is a frame 41, and the frame 41 includes a horizontal bar 411, a longitudinal bar 412 and an outer frame 413, at least one Punching knife 42 is arranged on cross bar 411, vertical bar 412 or cross bar 42 and longitudinal bar 412 intersections, and punching knife 42 is arranged on the middle part of cross bar 411, and the covered area of outer protective sheet 6 is equal to the covered area of outer explosion-proof sheet 2. area, the thickness of the inner explosion-proof dis...

Embodiment approach 3

[0068] see Figure 9As shown, the difference from Embodiment 1 is that the fixed frame of this embodiment is a supporting beam 401, and at least one punching knife 42 is arranged on the supporting beam 401. Preferably, the punching knife 42 is arranged in the middle of the supporting beam 401, and the inner explosion-proof disc The thickness of 3 and the thickness of outer explosion-proof disk 2 are both 0.25mm. Before the battery is abnormal or thermally out of control, the internal pressure or temperature of the battery is relatively high, so that the inner explosion-proof plate 3 is bulged, and the breakthrough structure 4 is in contact with the inner explosion-proof plate 3, and the punching knife 42 on the breakthrough structure 4 can pierce the inner explosion-proof Sheet 3 allows the explosion-proof material to enter the inside of the battery, which helps to slow down the thermal runaway of the battery. The support beam 401 cooperates with the clamping plates 403 at bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com