Chemical liquid stirring and mixing device and method

A technology for stirring and mixing liquids, which is applied to mixers, chemical instruments and methods, and mixers with rotary stirring devices. The effect is good and the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

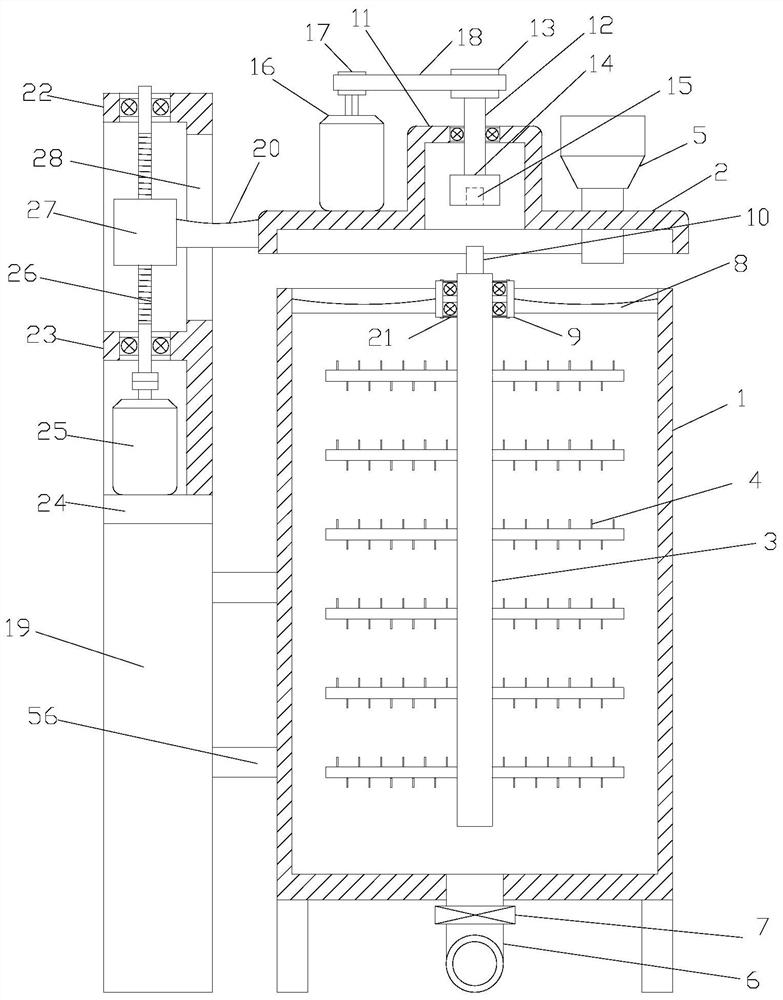

[0037]Such asfigure 1 As shown, the chemical liquid agitation mixing device described in this example, comprising a stirring tub 1 and a barrel cover 2, and a rotatable stirring rod 3 is provided in the stirring tub, a stirring structure 4, a barrel cover is provided on the stirring rod 3. 2 is provided with a feed tube 5; a discharge tube 6 is provided at the bottom of the stirring tub, and a valve 7 is provided on the discharge tube 6; characterized in:

[0038]The upper portion of the stirring tub is provided with a crossbar 8, and the center of the crossbar 8 is provided with a bearing housing 9, and the upper portion of the stirring rod 3 is in the bearing of the bearing housing 9; the top of the stirring rod 3 is provided with a cross section. Shaped bumps 10;

[0039]The tank cover 2 is provided with a lifting chamber 11, and a rod 12 is provided in the bearing of the top surface of the lifting chamber 11, and the top portion of the rotor 12 is provided with a driven wheel 13, and ...

Embodiment 2

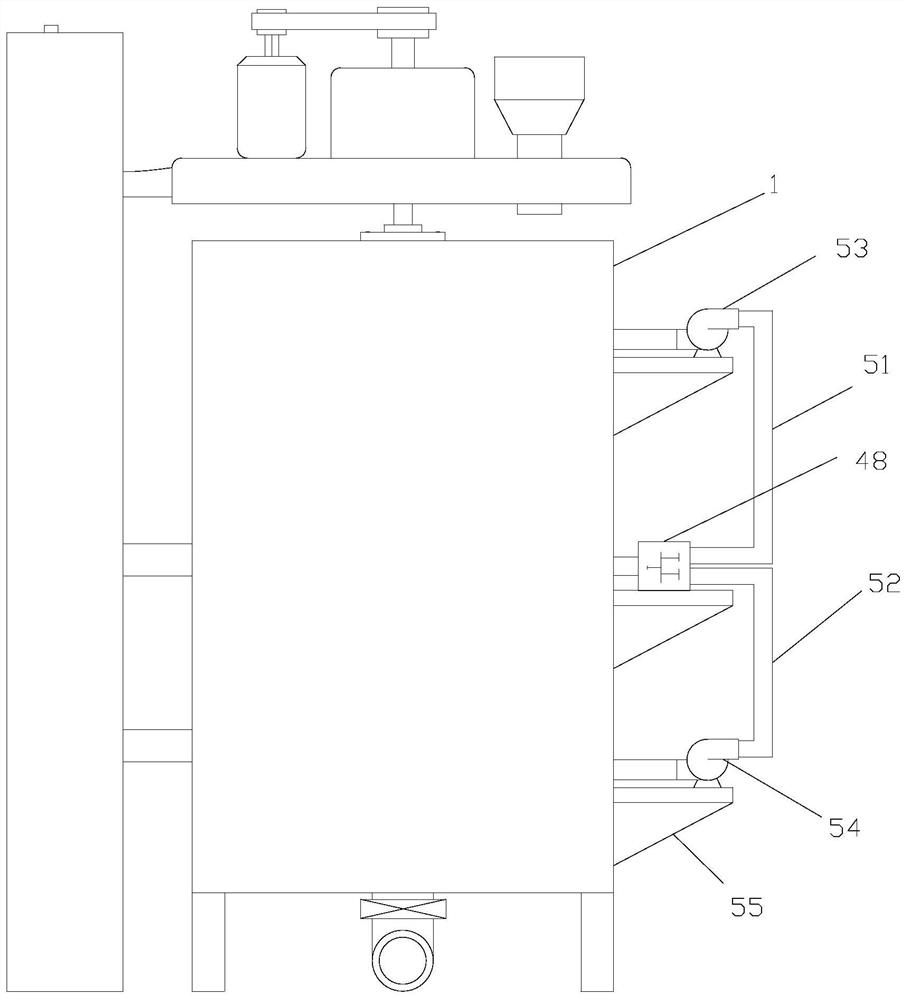

[0047]Such asimage 3 ,4As shown, the chemical liquid agitation mixing device described in this example, comprising a stirring tub 1 and a barrel cover 2, and a rotatable stirring rod 3 is provided in the stirring tub, a stirring structure 4, a barrel cover is provided on the stirring rod 3. 2 is provided with a feed tube 5; a discharge tube 6 is provided at the bottom of the stirring tub, and a valve 7 is provided on the discharge tube 6; characterized in:

[0048]Such asFigure 5 The upper portion of the mixing tank 1 is provided with a crossbar 8, and a bearing housing 9 is provided in the center of the crossbar 3, and the upper portion of the stirring rod 3 is in the bearing of the bearing housing 9; the top of the stirring rod 3 is provided with a cross section Circular bumps 10;

[0049]The tank cover 2 is provided with a lifting chamber 11, and a rod 12 is provided in the bearing of the top surface of the lifting chamber 11, and the top portion of the rotor 12 is provided with a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com