Preparation method of chloroprene rubber asphalt waterproof paint

A kind of asphalt waterproof coating and neoprene technology, which is applied in the direction of grain processing, etc., can solve the problems of difficult feeding of cutters, high accumulation of asphalt blocks, and inability of asphalt blocks to be decomposed and unloaded, so as to improve the cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

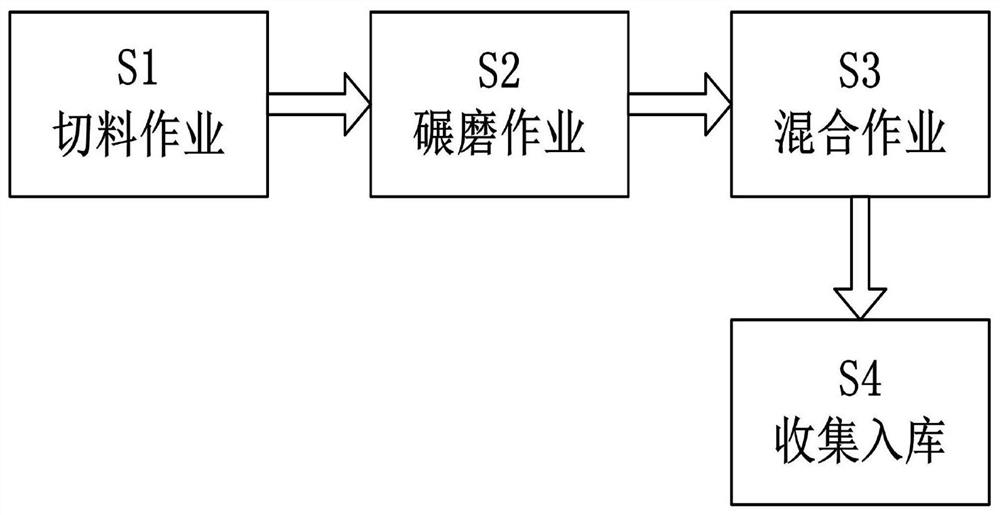

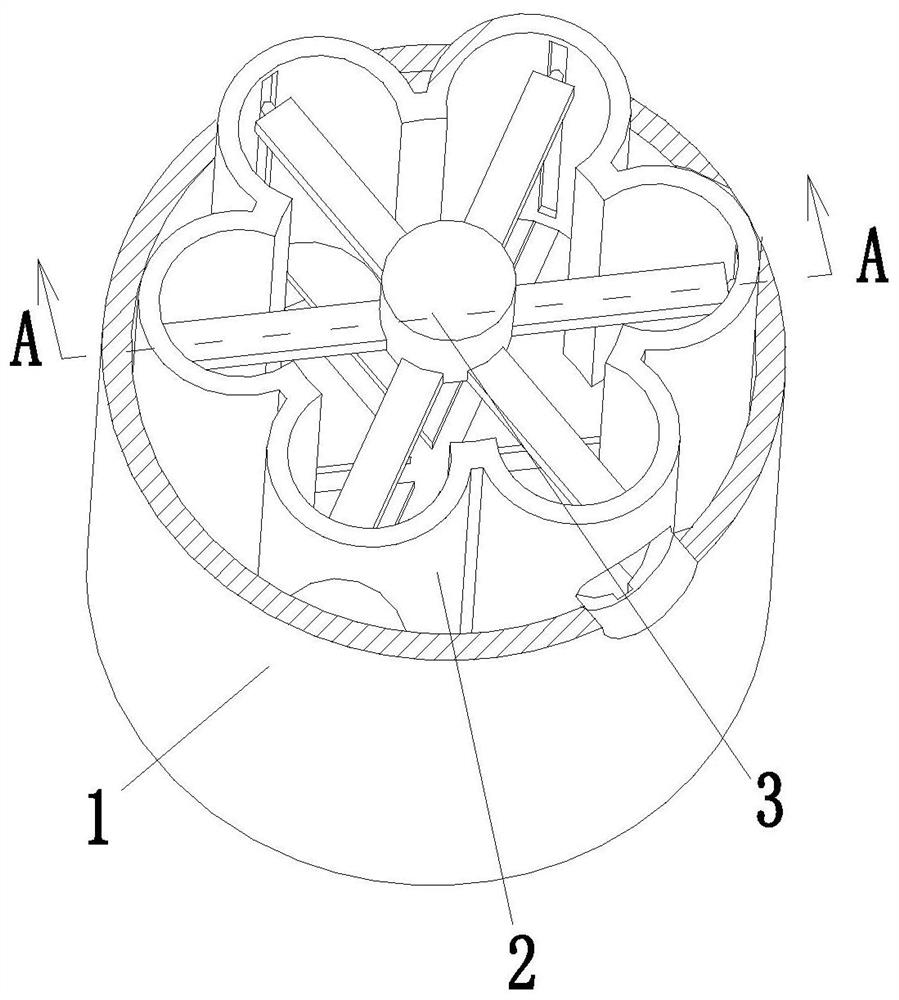

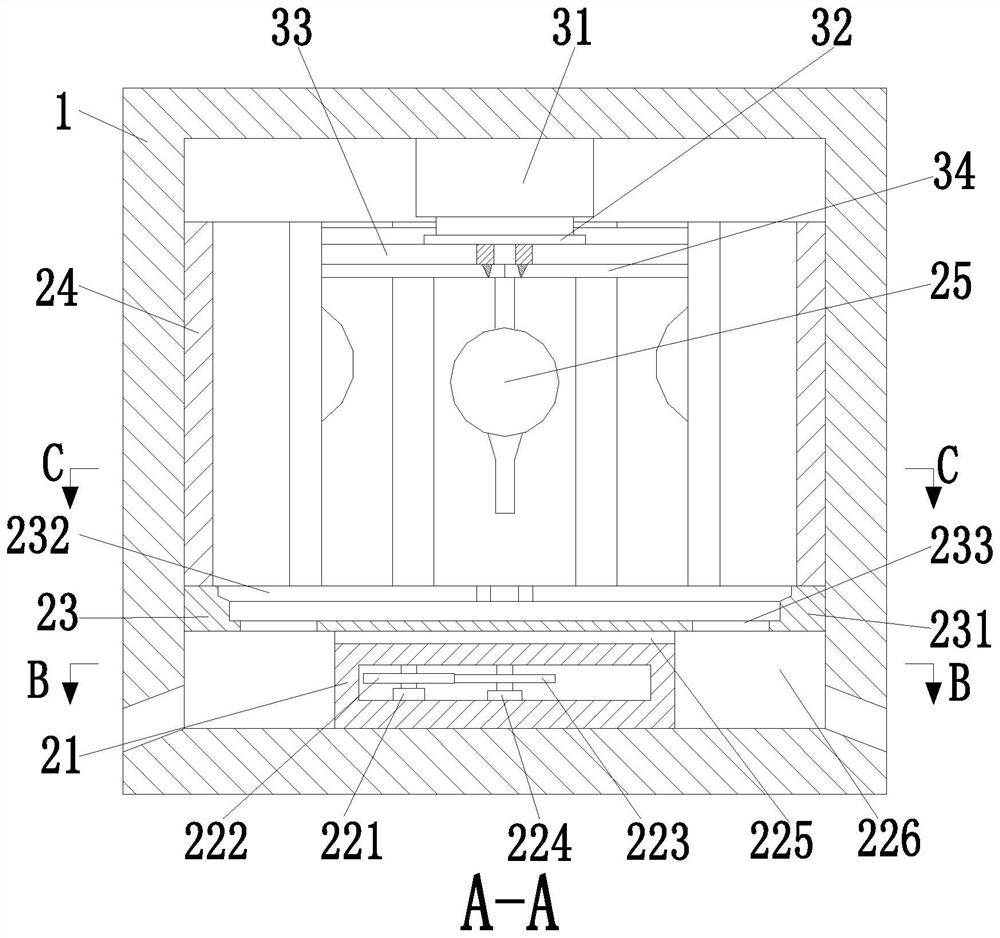

[0031] Such as Figure 1 to Figure 6 A kind of preparation method of neoprene asphalt waterproof coating shown, it has used asphalt material cutting equipment, and asphalt material cutting equipment comprises cutting cylinder 1, uniform feeding device 2 and pelletizing and unloading device 3 adopts this asphalt material cutting equipment to The production process of waterproof coating also includes the following steps:

[0032] S1. Cutting operation: use the asphalt cutting equipment to decompose the asphalt into small pieces of uniform size;

[0033] S2. Grinding operation: Grinding asphalt into fine powder manually or mechanically;

[0034] S3. Mixing operation: mix asphalt powder and neoprene powder and stir evenly;

[0035] S4, collection and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap