Building reinforcing steel bar cut-off device

A cutting device and a technology for building steel bars, which are applied in the field of building steel bar cutting devices, can solve the problems of inconvenient adjustment of the places where steel bars are to be cut off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

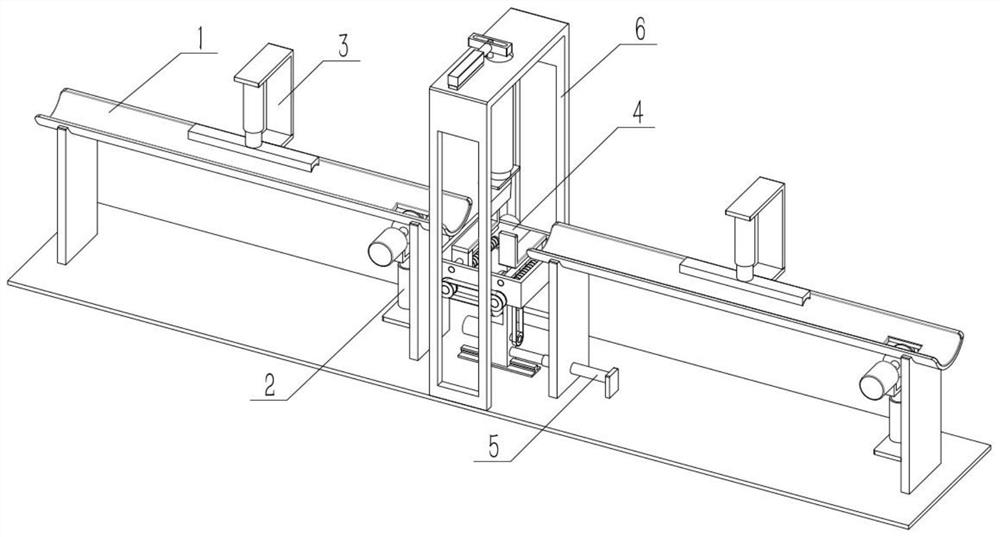

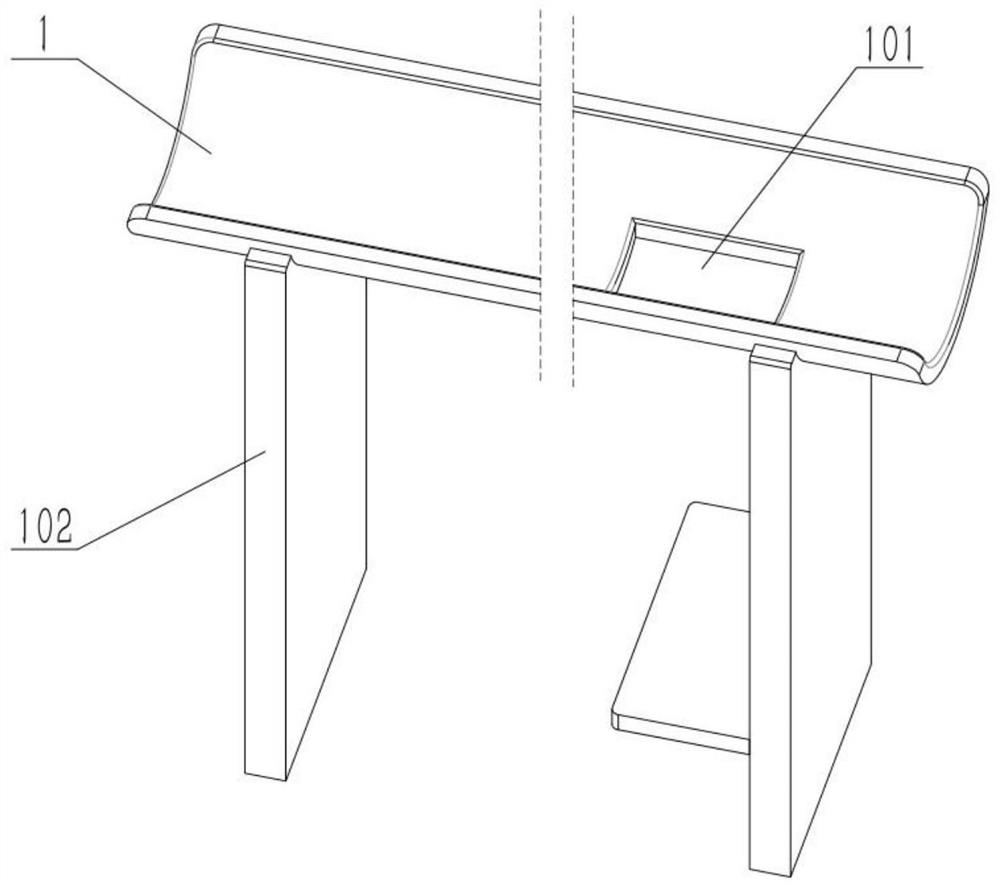

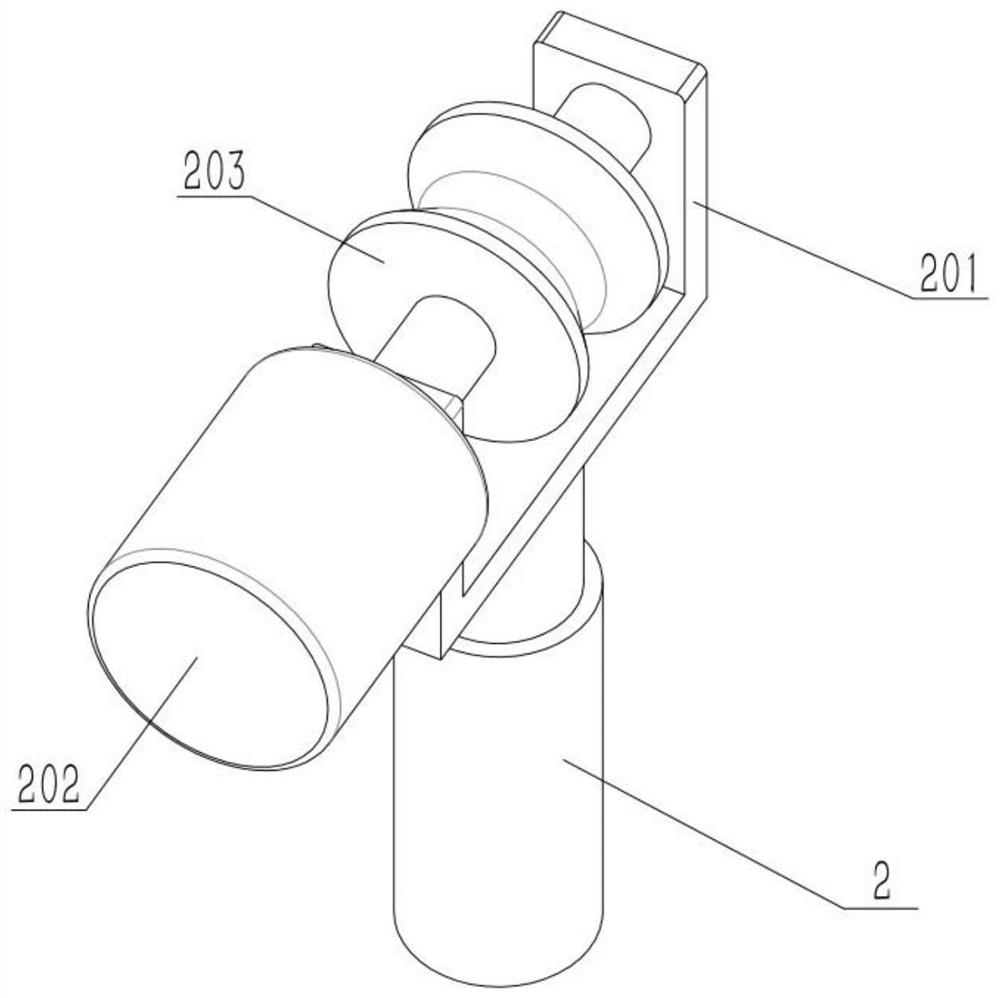

[0030] As shown in the figure, a building reinforcement cutting device includes an auxiliary mechanism, the auxiliary mechanism includes a half-arc guide bracket 1, a passage port 101, a support plate 102, an electric push rod 2, a half-wrapped seat 201, a motor I 202 and a guide wheel 203, the right side of the half-arc guide bracket 1 is provided with a passage opening 101, the left and right sides of the lower end of the half-arc guide bracket 1 are fixedly connected to the support plate 102, and the movable end of the electric push rod 2 is fixedly connected to the half-wrapped seat 201, and the half-wrapped seat 201 The rear end of the motor I202 is fixedly connected, and the output shaft of the motor I202 is connected to the front and rear ends of the half-pack seat 201. The guide wheel 203 is fixedly connected to the middle of the output shaft of the motor I202. The guide wheel 203 is located directly below the passage port 101. The push rod 2 is fixedly connected to the...

specific Embodiment approach 2

[0033] As shown in the figure, the auxiliary mechanism also includes a mounting frame 3, an electric push rod II 301 and a bead 302. The front end of the half-arc guide bracket 1 is fixed to the mounting frame 3, and the upper end of the mounting frame 3 is fixed to the electric push rod II 301. The movable end of the electric push rod II 301 is fixedly connected to the bead 302, which is located directly above the semi-arc guide bracket 1, and the lower end of the bead 302 is provided with a bar-shaped arc. When cutting the steel bar, it is necessary to fix the steel bar, start the electric push rod II 301, the electric push rod II 301 drives the bead 302 to descend, and utilize the bead 302 to hold the steel bar on the semi-arc guide bracket 1, so that the steel bar cannot move.

specific Embodiment approach 3

[0035] As shown in the figure, there are two auxiliary mechanisms in a linear array, and the distance between the inner end surfaces of the two semi-arc guide brackets 1 is 10 to 30 cm.

[0036] Place the left and right sides of the steel bars on the two semi-arc guide brackets 1 correspondingly, and then after the cross-cutting position is suspended, the left and right sides of the cutting-off position are supported and fixed, so that the steel bars will not be cut when the cutting force is applied to the cutting-off position. Lifting or movement occurs to ensure the cutting quality. The truncated right end utilizes the guide wheel 203 located on the right side to convey this section of steel bar away, thereby facilitating the formation of an assembly line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com