Barrel beehive chamfering equipment for animal husbandry

A technology for animal husbandry and beehives, which is applied in the field of beehive chamfering equipment for animal husbandry. It can solve the problems of speeding up the chamfering efficiency, uneven corners poured from the inner wall of the beehive barrel, and large energy consumption, so as to improve the chamfering efficiency. Angular efficiency, effect of shortening placement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

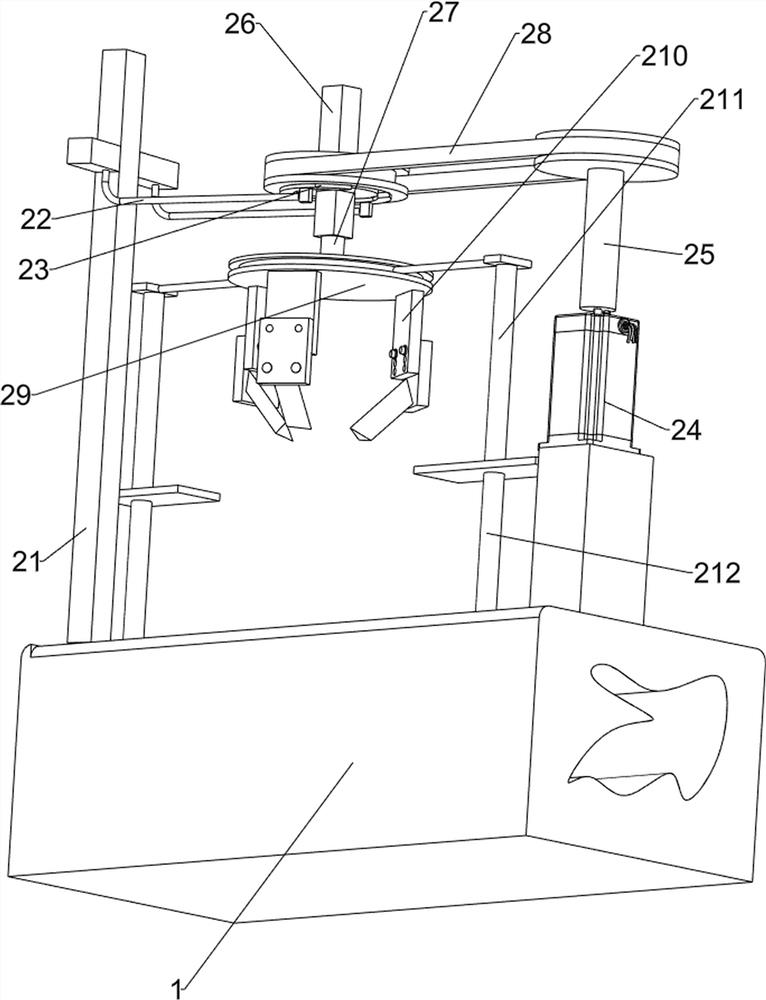

[0064] A drum beehive chamfering equipment for animal husbandry, such as figure 1 As shown, it includes a base plate 1 , a cutting mechanism 2 and a clamping and positioning mechanism 3 , the cutting mechanism 2 is provided on the top of the base plate 1 , and the clamping and positioning mechanism 3 is installed on the top of the base plate 1 .

[0065] When the worker needs to chamfer the drum beehive, the worker first needs to place the drum beehive in the middle of the top of the bottom plate 1, the drum beehive will push the clamping positioning mechanism 3 to move outward, and the clamping positioning mechanism 3 will reset. The clamping and positioning mechanism 3 will clamp and fix the drum beehive, and then the worker starts the cutting mechanism 2 to rotate, and then manually presses the cutting mechanism 2 downwards, and the cutting mechanism 2 moves downward to chamfer the drum beehive. After the mechanism 2 completes the chamfering work of the drum beehive, the wo...

Embodiment 2

[0067] In a preferred embodiment of the present invention, as figure 2 As shown, the cutting mechanism 2 includes a first support frame 21, a connecting rod 22, a support arc block assembly 23, a first motor 24, a first rotating shaft 25, a rotating block 26, a second rotating shaft 27, a first transmission assembly 28, and a turntable 29. Cutter assembly 210, support assembly 211 and first extension rod 212. A first support frame 21 is provided on the middle right side of the top of the bottom plate 1. The upper part of the first support frame 21 is symmetrically provided with a connecting rod 22. The inner end of the connecting rod 22 rotates at the top There is a supporting arc block assembly 23, the left side of the top of the bottom plate 1 is connected with a first motor 24 by bolts, the output shaft of the first motor 24 is connected with a first rotating shaft 25, and the sliding type in the middle of the supporting arc block assembly 23 is provided with a rotating sha...

Embodiment 3

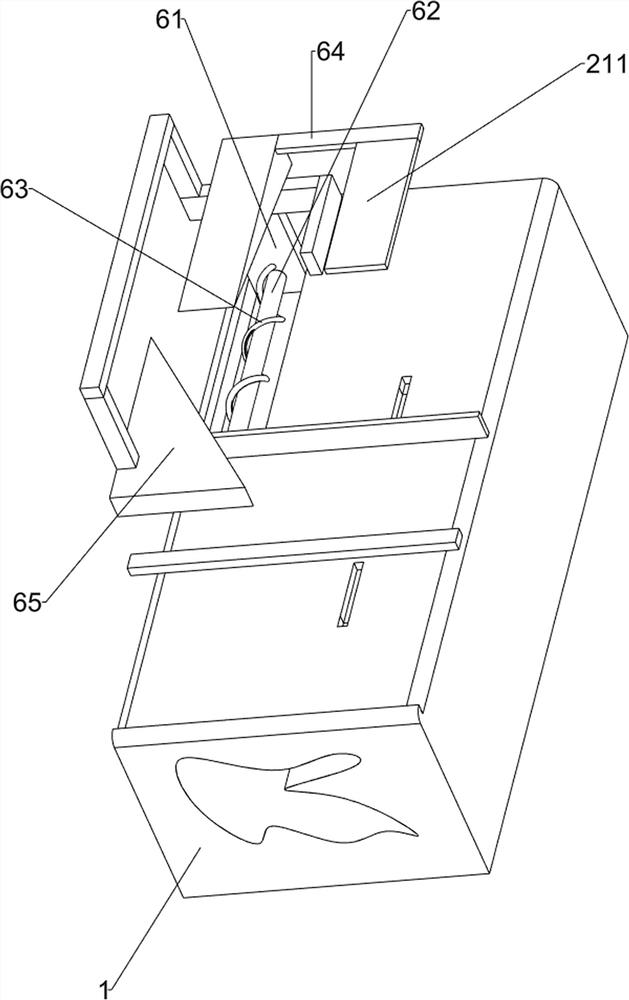

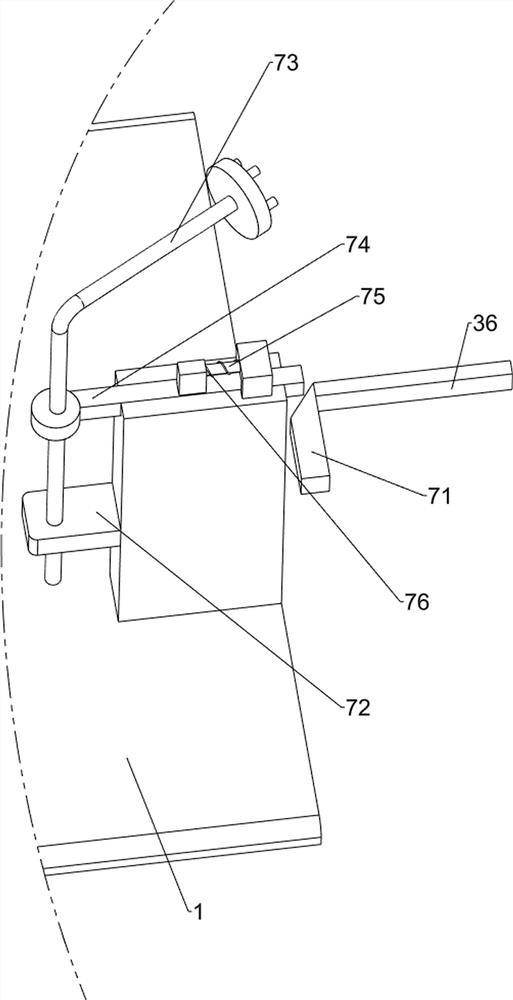

[0070] In a preferred embodiment of the present invention, as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the clamping positioning mechanism 3 includes a first wedge fast 31, a second telescopic rod 32, a clamp block assembly 33, a first spring 34, a third telescopic rod 35, a first baffle plate 36 and a second spring 37, both The inner side of the bottom end of the first extension rod 212 is fixedly connected with the first wedge-shaped fastening 31, and the middle of the top of the bottom plate 1 is symmetrically provided with the second telescopic rod 32, and the outer end of the second telescopic rod 32 is slidably provided with a clamping block assembly 33. The two telescopic rods 32 are equipped with a first spring 34, and the two ends of the first spring 34 are connected to the clamping block assembly 33 and the second telescopic rod 32 respectively, and the outside of the clamping block assembly 33 is provided with a third telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com