Cutting scrap iron multi-angle collecting device for machining

A technology of mechanical processing and collection devices, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of iron scrap leakage in collection capacity, increase in collection capacity, and inability to strengthen fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

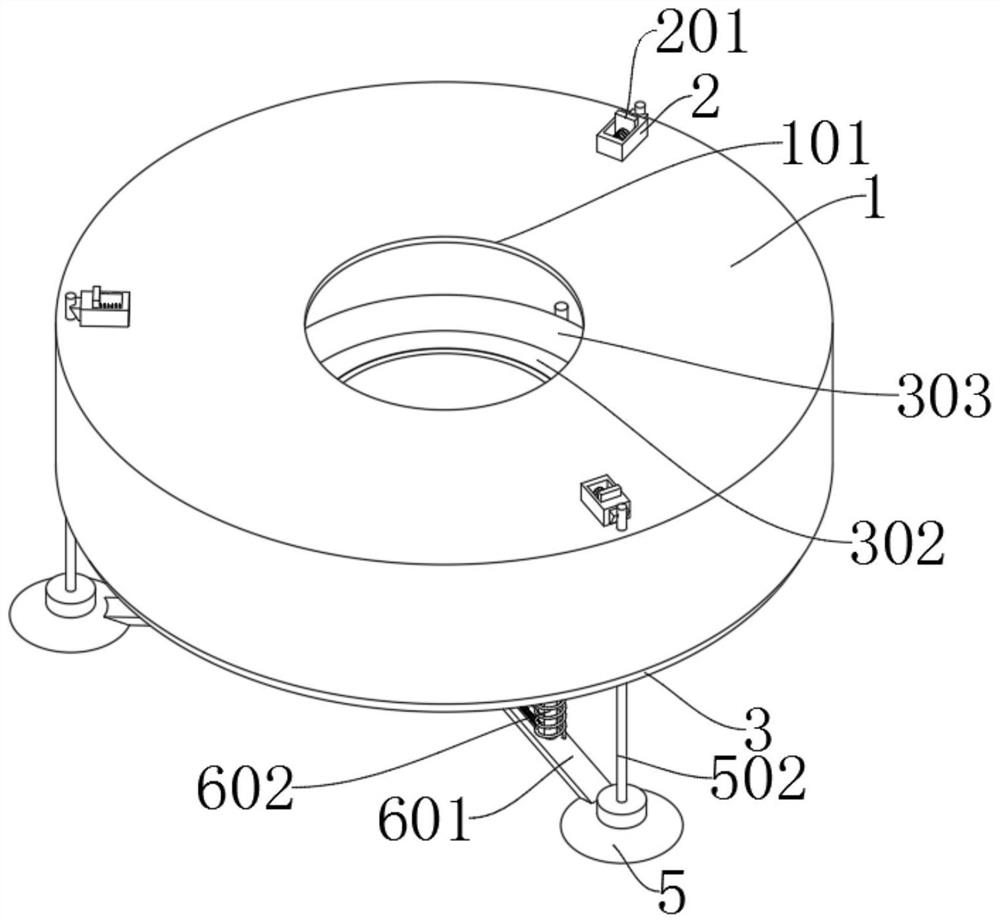

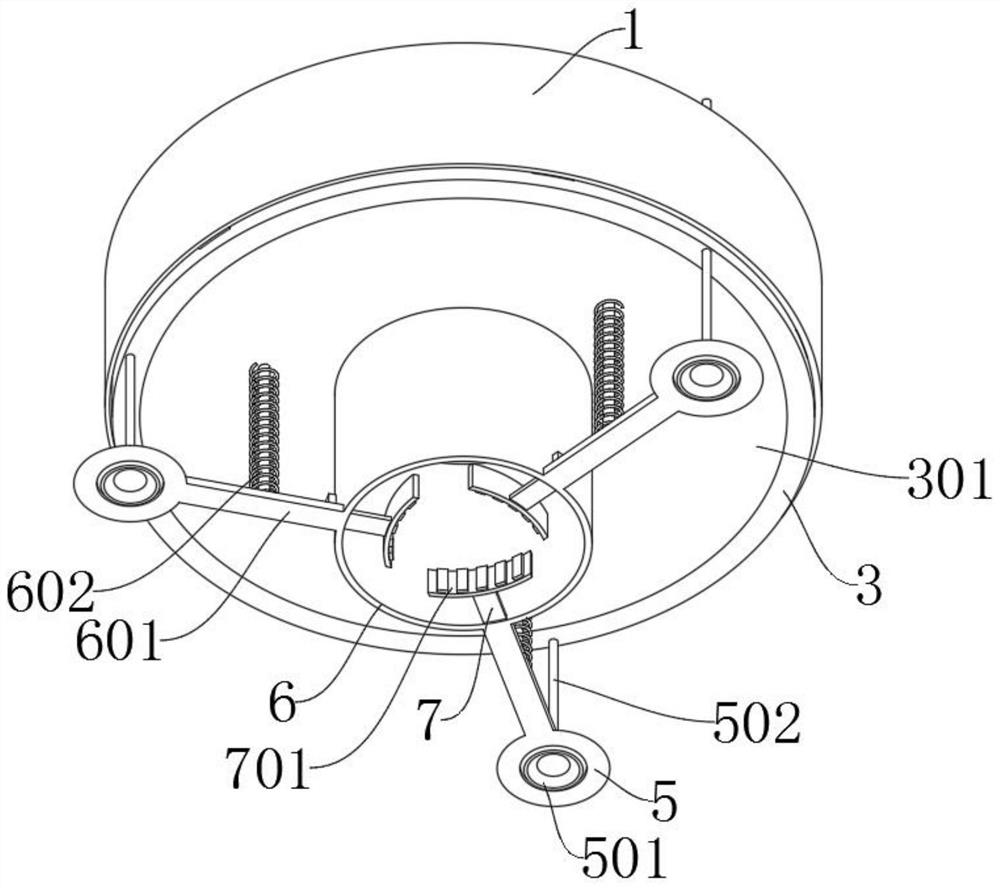

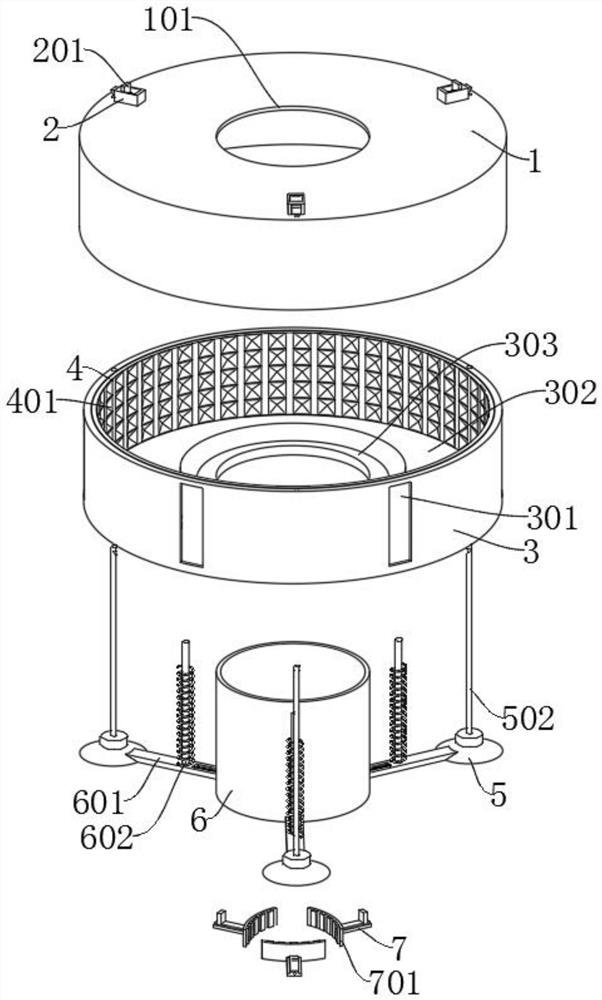

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a multi-angle collection device for cutting iron scraps for mechanical processing, which includes a main body 1, a mounting part 2, a moving part 3, an inner part 4, a supporting part 5, a lower part 6 and a pushing part 7; the main body 1 has a circular structure, And the bottom of the main body 1 is provided with a round groove, and the top of the main body 1 is provided with a round hole; the mounting part 2 is installed on the top of the main body 1, and the mounting parts 2 are arranged in a ring; the inner part 4 is embedded and installed inside the moving part 3 , and the bottom of the inner part 4 is in contact with the top of the bottom plate 302; the support 5 is at the bottom of the main body 1 and the moving part 3, and the support 5 is arranged in a ring shape, and the guide rod 502 at the top of the support 5 is inserted through the main body 1 And the inside of the round hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com