Manipulator tool clamping mechanism

A clamping mechanism and manipulator technology, applied in the field of manipulators, can solve problems such as low fault tolerance rate, tool drop, tool damage, etc., to achieve the effect of increasing fault tolerance rate, preventing tool drop, and avoiding damage to tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific embodiments. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

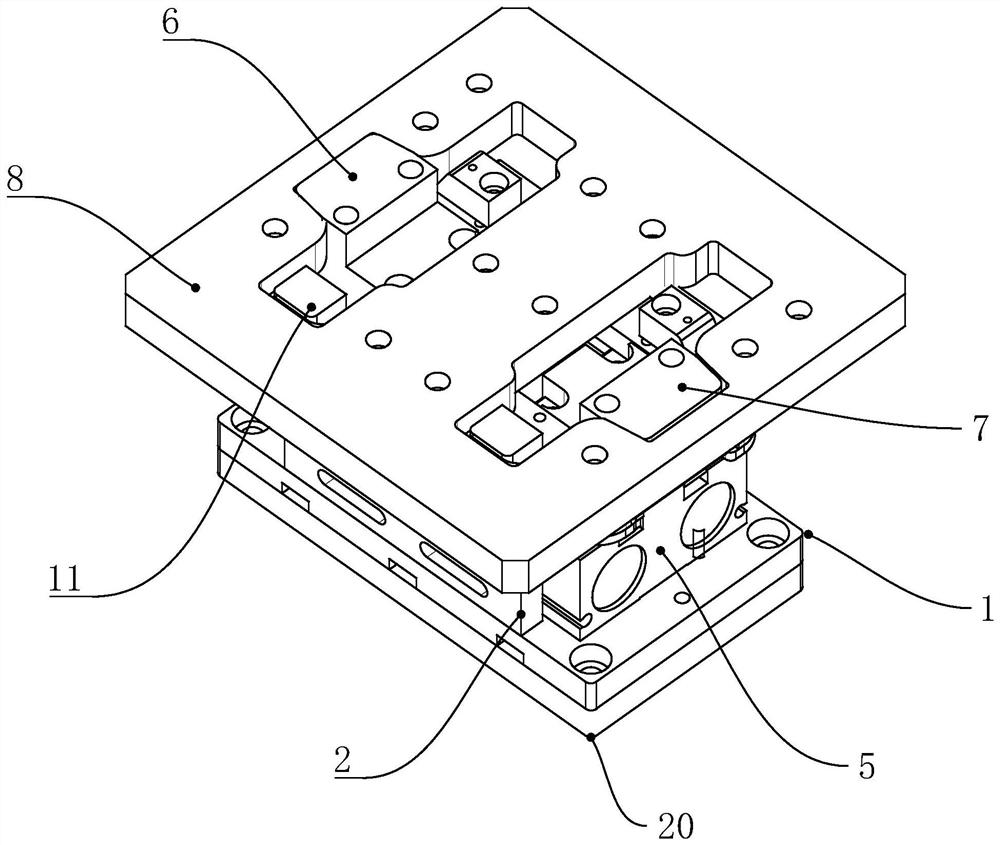

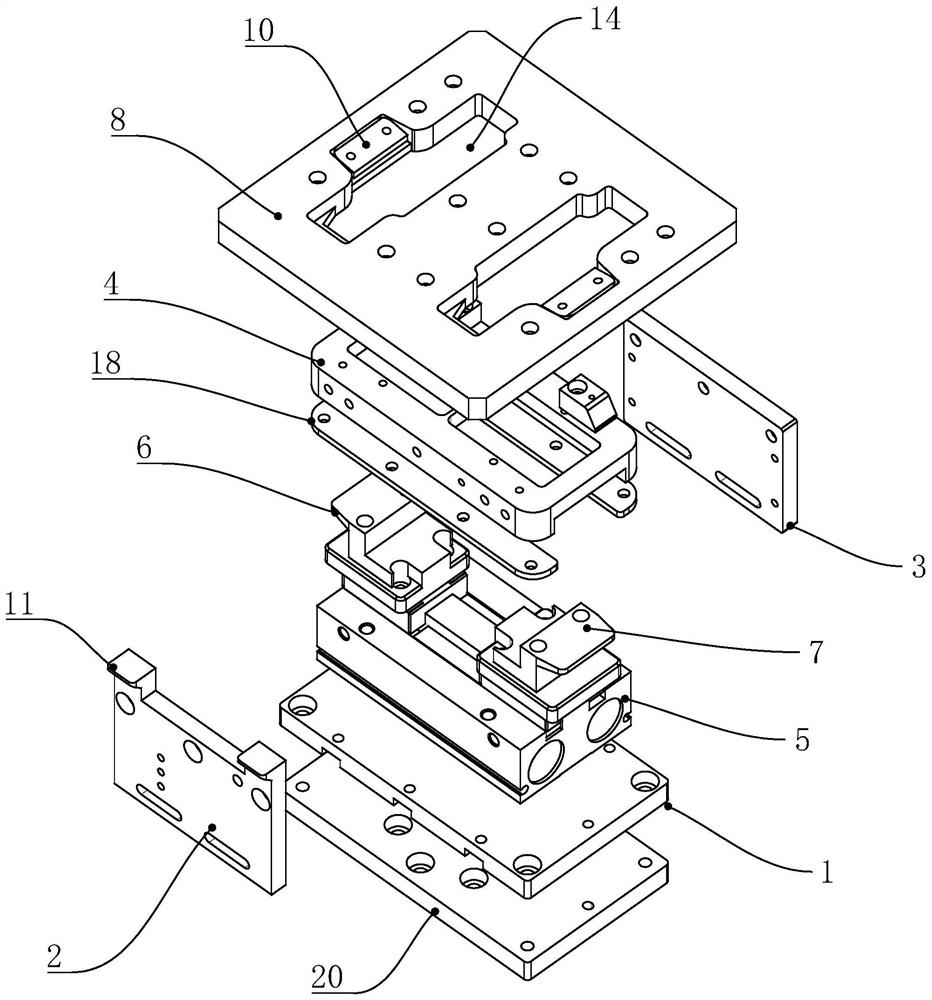

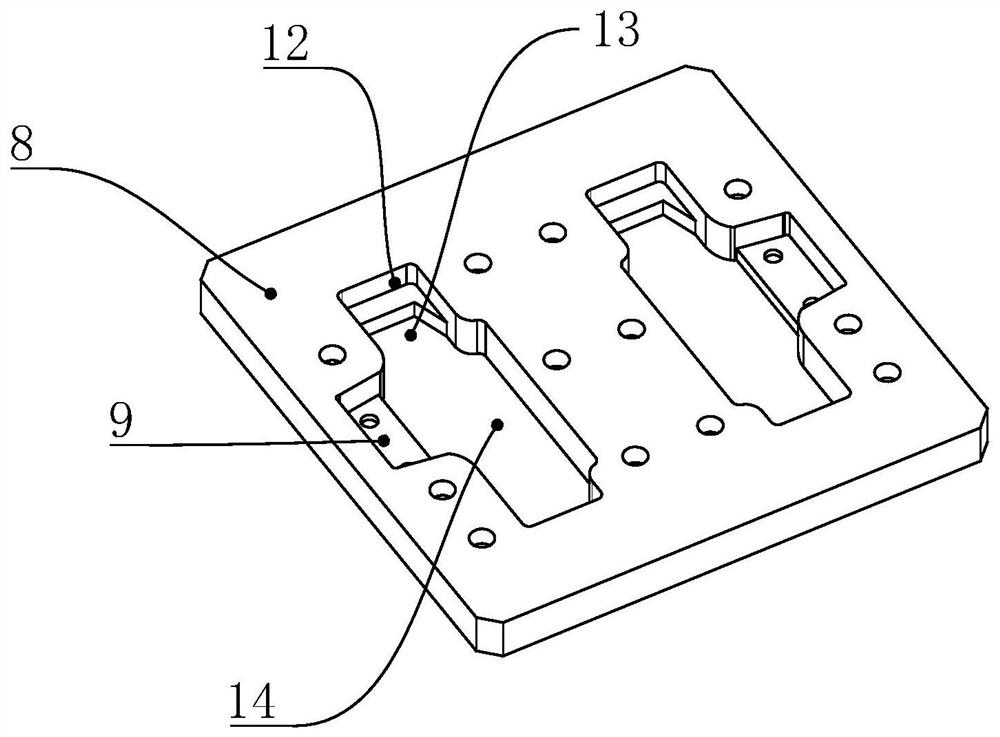

[0026] Such as Figure 1-5 As shown, the manipulator tool clamping mechanism is shown, including a fixed seat 1, a hook plate 2, a first fixed block 3, a second fixed block 4, a clamping cylinder 5, a first clamping block 6, a second clamping block 7 and tools plate 8, the hook plate 2 and the first fixing block 3 are arranged on both sides of the fixing seat 1, and the second fixing block 4 is arranged between the hook plate 2 and the first fixing block 3 Between, the clamping cylinder 5 is arranged between the fixing base 1 and the second fixing block 4, the first clamping block 6 and the second clamping block 7 are connected to the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com