Adhesive tape pressing mechanism

A technology for pressing tapes and racks, which is applied in metal processing and other directions, and can solve problems such as warped tapes, insufficient vacuum suction force of suction nozzles, and affecting tape replacement efficiency, and achieve the effect of improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

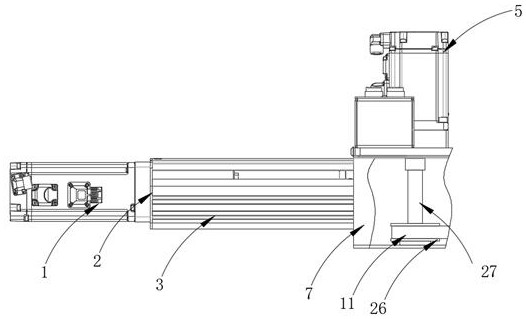

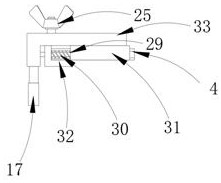

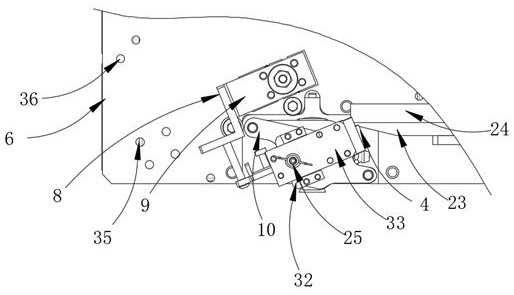

[0029] See Figure 1-5 The present invention provides a technical solution: a compact tape mechanism comprising a frame 7, a top surface of the frame 7 having a first plate body 6, a servo motor 5, servo motor 5, servo motor 5, servo motor 5 The output terminal penetrates the upper surface of the first plate body 6 and fixedly connected to the third rod 27, and the outer wall welded of the third rod 27 has a second rotary wheel 26, and one end of the bottom portion of the third rod 27 is rotated through the bearing to the rack. The bottom of the inner wall of the frame 7, the bottom of the frame 7 is rotated by the bearing, and the outer side wall of the first rotary wheel and the outer wall of the first rotary wheel and the outer wall of the second rotary wheel are transferred thereon, and the belt 11, the first The inner side wall of the runner 12 welded the roller 13, and the outer wall of the roller 13 is welded with a first turntable 14, and the upper surface of the first turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com