Adjustable rotary cutter device for plastic dripping machine

A technology of rotating cutters and drop molding machines, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problem of affecting the processing accuracy of drop molding machines on products, affecting work efficiency, and cleaning of embossing rollers And other problems, to achieve the effect of preventing angle misalignment, all-round multi-angle adjustment, and improving clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention is further clarified in conjunction with the accompanying drawings and embodiments, and it is to be understood that the invention is intended to illustrate the invention and is not intended to limit the scope of the invention. It should be noted that the words "front", "" "", "", ",", ",", ",", ",", ",", ",", ",", ",", "," inside "and" outside " "Forders referring to or away from the direction of the geometry center of the particular component.

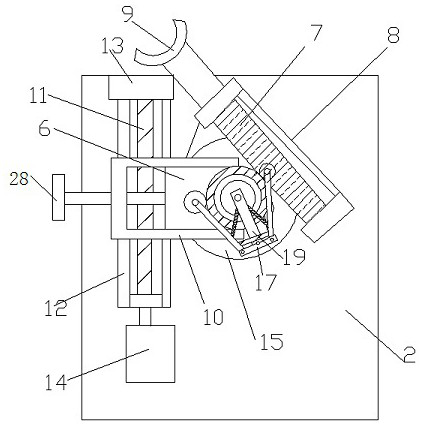

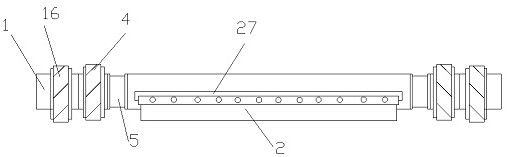

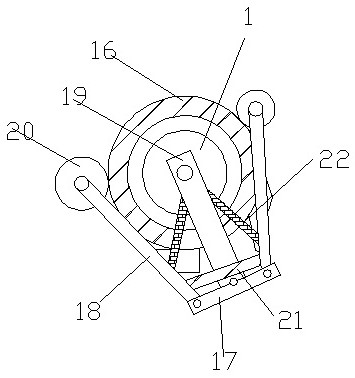

[0023] Such as Figure 1-5 As shown, the dripping machine of the present embodiment is adjusted to rotate the cutter, including a knife shaft 1, wherein the knife shaft 1 is disposed within the frame 2 of the dripper; the tool 3 is fixed by the lock plate 27 The knife shaft 1 is on.

[0024] Among them, both ends of the knife shaft 1 are sequentially provided with a first adjustment gear 4; wherein the lateral adjustment board 6 is engaged with the fitting groove 5; the worm 7 is engaged with the first adjustment gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com