Method of automatic device for rapidly switching fixture modules

An automatic equipment and fast switching technology, which is applied in metal processing and other directions, can solve problems such as time-consuming and labor-intensive, and achieve the effects of reducing production costs, compact structure, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

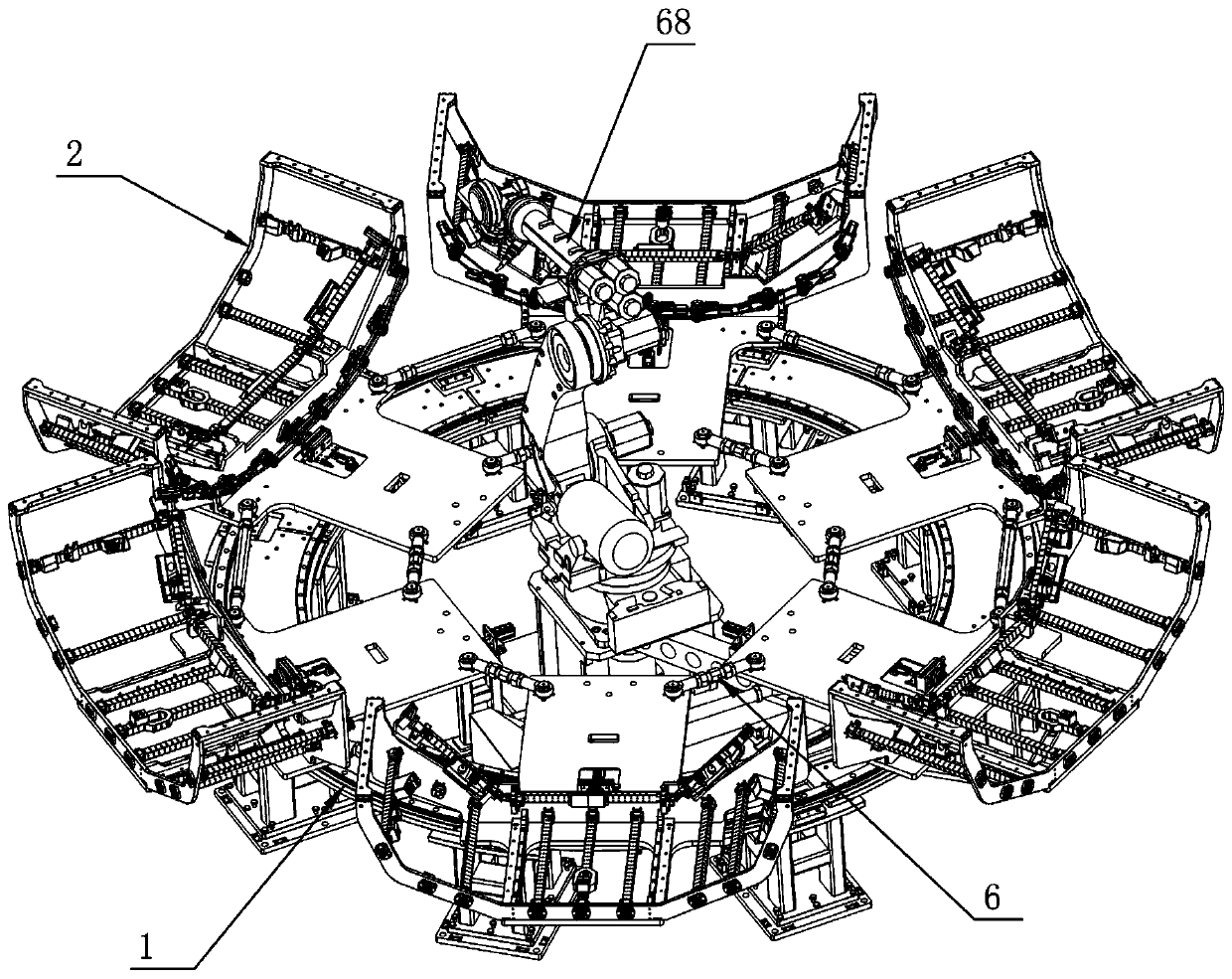

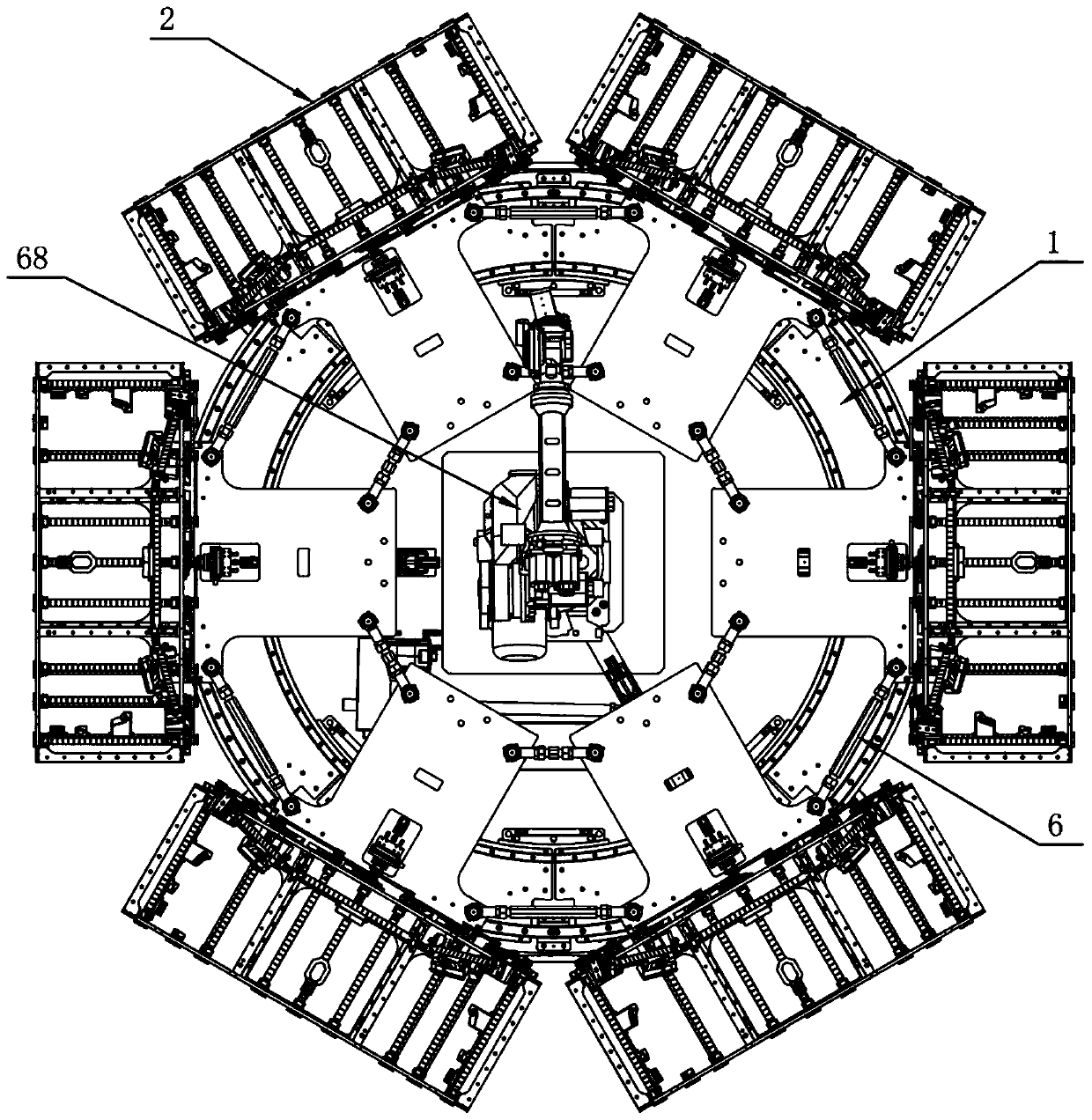

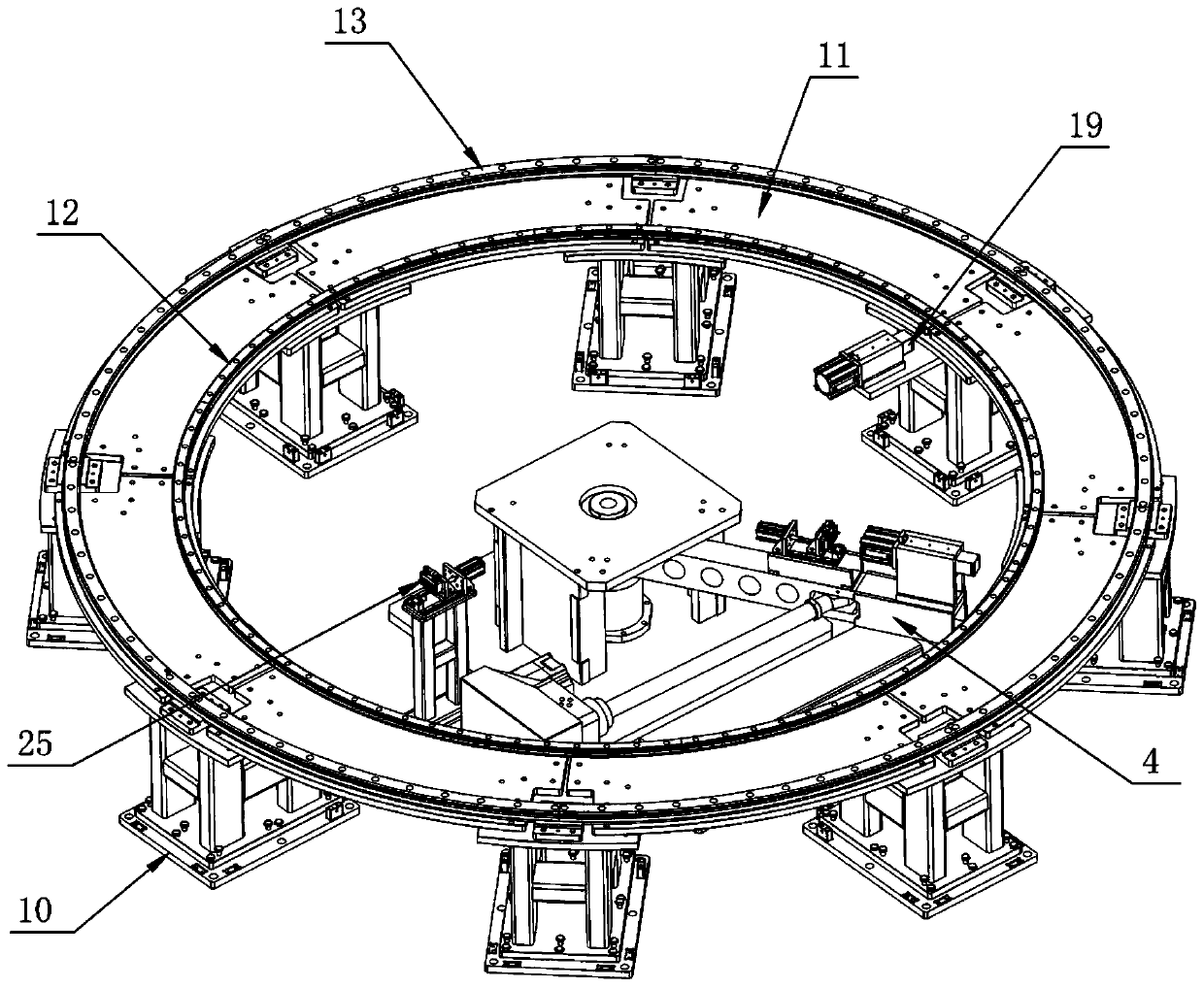

[0049] refer to Figure 1 to Figure 18 , the present invention provides a kind of automation equipment and method thereof for rapidly switching tire mold groups, the method for quickly switching the automation equipment of tire mold groups comprises the following operation steps:

[0050] Step S001, the workpiece carrying unit is clamped and positioned, and the locking drive mechanism 19 on the screw feeding assembly 4 of the circular transfer table 1 is used to drive the locking block 30 to lock with a corresponding workpiece carrying unit 5 on the linkage carrying assembly 2 Positioning; step S002, connect the electricity, drive the electrical male plug 27 to cooperate with the electrical female plug 40 at the bottom of the workpiece carrying unit 5 through the electrical connection mechanism 25 on the screw feeding assembly 4, and complete the electrical connection; step S003, carry the quadrangular prism Rotation switching, the film reversing positioning assembly 35 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com