Quick loading and unloading device for port cargoes

A loading and unloading device and cargo technology, which is applied in the field of cargo handling and loading and unloading, can solve the problems of low efficiency and achieve the effect of compact structure and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

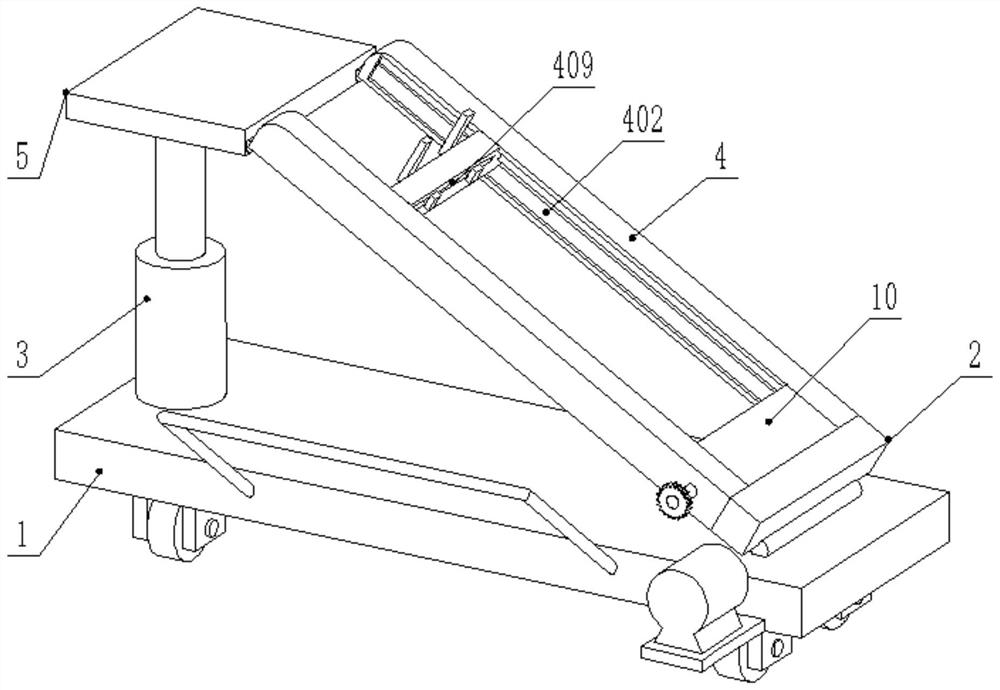

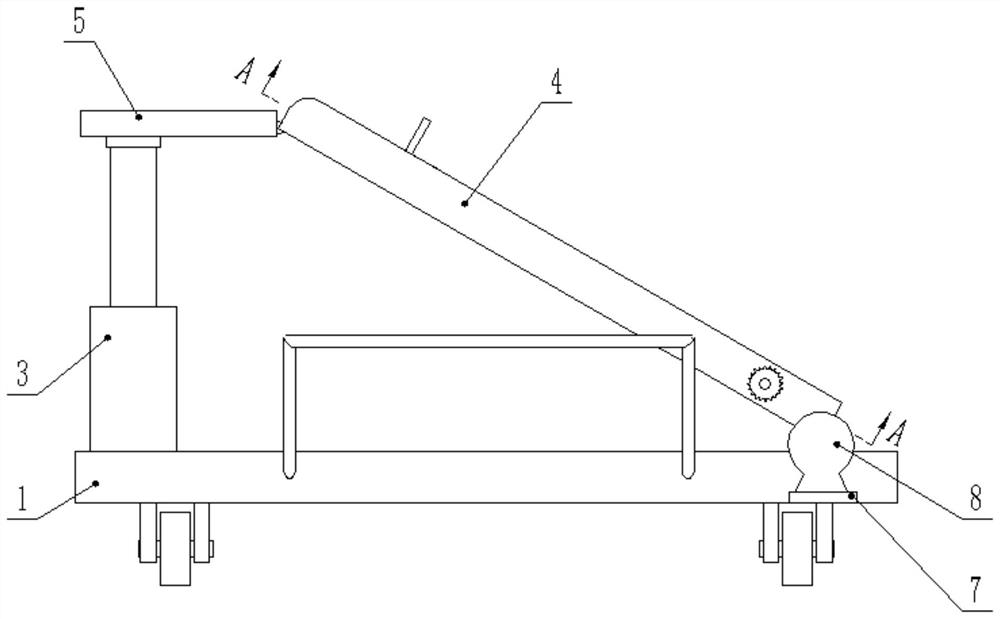

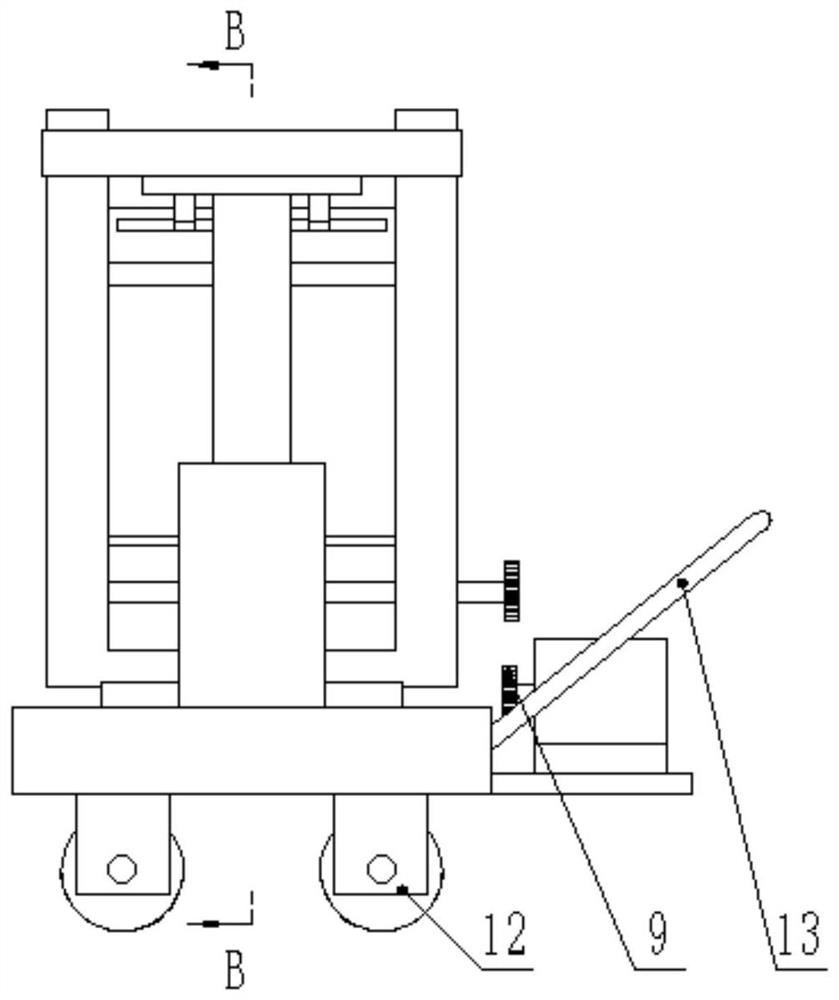

[0025] Example 1: Please refer to figure 1 , a fast loading and unloading device for port goods, comprising a base 1, a connecting plate 2 is hinged on the right side of the base 1, a hydraulic rod 3 is arranged on the left side of the base 1, and a lifting assembly 4 is fixedly connected to the connecting plate 2. The upper end of the assembly 4 is hinged with a horizontal plate 5, the upper end of the hydraulic rod 3 is fixedly connected with a guide plate 6, and the lower surface of the horizontal plate 5 is connected with the guide plate 6;

[0026] see Figure 5 , the lower surface of the horizontal plate 5 has a limiting chute 11, and the guide plate 6 is slidably connected with the horizontal plate 5 through the limiting chute 11;

[0027] By controlling the hydraulic rod 3 to adjust the height of the horizontal plate 5, due to the cooperation of the limit chute 11 and the guide plate 6, the horizontal plate 5 is kept horizontal to meet the requirements of different lo...

Embodiment 2

[0036] Embodiment two: this embodiment supplements on the basis of the previous embodiment:

[0037] see figure 1 , a fast loading and unloading device for port goods, comprising a base 1, a connecting plate 2 is hinged on the right side of the base 1, a hydraulic rod 3 is arranged on the left side of the base 1, and a lifting assembly 4 is fixedly connected to the connecting plate 2. The upper end of the assembly 4 is hinged with a horizontal plate 5, the upper end of the hydraulic rod 3 is fixedly connected with a guide plate 6, and the lower surface of the horizontal plate 5 is connected with the guide plate 6;

[0038] see Figure 5 , the lower surface of the horizontal plate 5 has a limiting chute 11, and the guide plate 6 is slidably connected with the horizontal plate 5 through the limiting chute 11;

[0039] By controlling the hydraulic rod 3 to adjust the height of the horizontal plate 5, due to the cooperation of the limit chute 11 and the guide plate 6, the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com