A Heat Treatment Method for Laser Selective Melting and Forming Nickel-based Superalloy

A nickel-based superalloy, laser selective melting technology, used in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problem of mechanical properties not meeting the development needs, etc., to weaken the growth tendency, improve low-temperature plasticity, toughness, fine The effect of grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

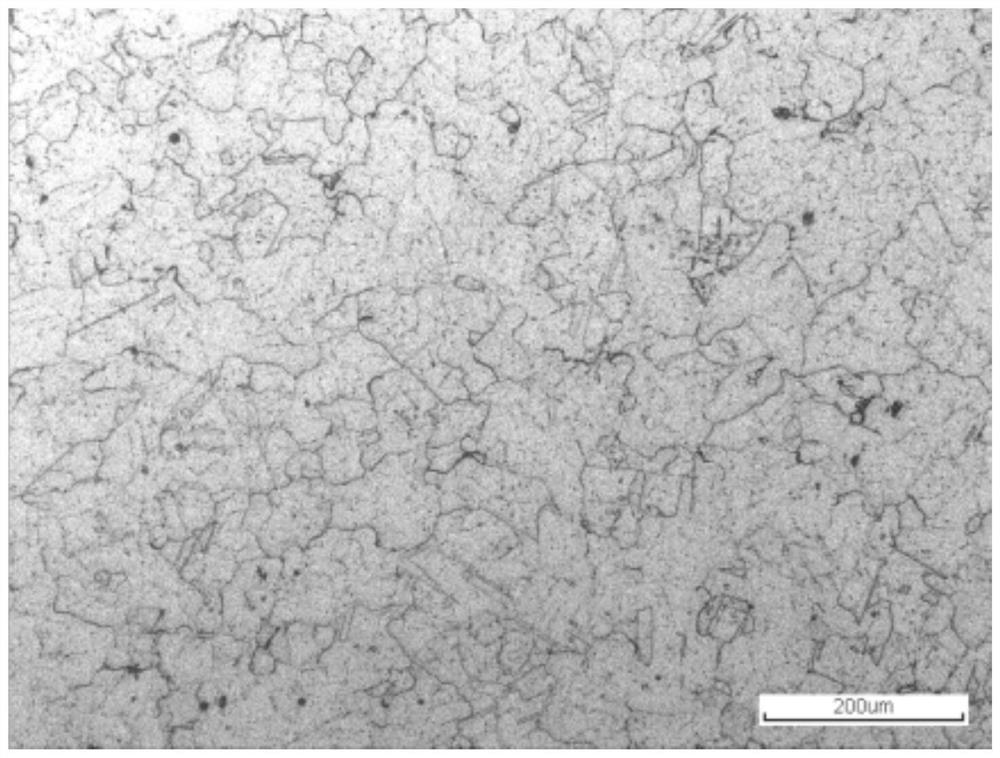

Image

Examples

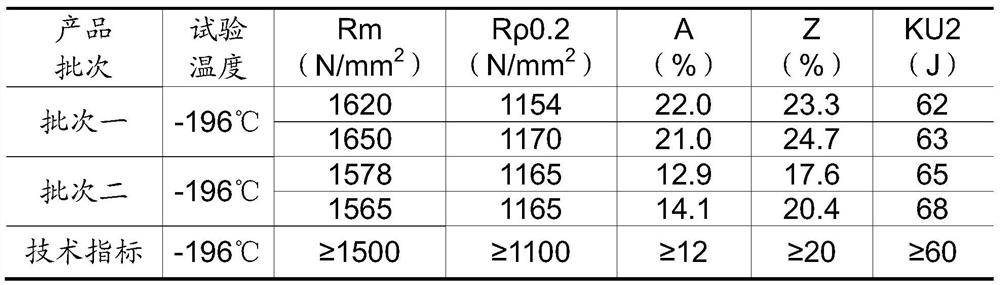

Embodiment 1

[0030] Take a certain type of engine turbo pump centrifugal wheel as an example.

[0031] (1) The workpiece is made of nickel-based superalloy by laser selective melting.

[0032] (2) Heat treatment: the centrifugal wheel after separating the substrate is heat treated in a vacuum heat treatment furnace. The pressure in the furnace is not more than 10 -3 Pa, after the environment in the furnace meets the requirements, raise the temperature from room temperature to 900°C for 0.5h, then raise the temperature to 1065°C for 4h, after the heat preservation is completed, backfill with argon to cool, and the pressure of backfill with argon is 3.0×10 5 Pa, immediately start the stirring fan in the equipment, cool to below 80°C and leave the furnace for air cooling; then heat treatment in a vacuum heat treatment furnace, the pressure in the furnace is not greater than 10 -3 Pa, after the environment in the furnace meets the requirements, heat it up to 735°C and keep it warm for 10 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com