Formula of low-alloy electrode for -50 DEG C spherical tank made of 07MnNiMoDR steel and production process thereof

A production process, low-alloy technology, applied in the direction of manufacturing tools, metal processing equipment, welding media, etc., can solve the problems affecting the construction progress, long procurement cycle, foreign exchange consumption, etc., to achieve excellent comprehensive performance and low sensitivity to cold cracks , Good effect of welding process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A formula of low-alloy electrode for 07MnNiMoDR steel-50℃ spherical tank, including welding core and coating, the mass percentage of its chemical composition is: C: 0.067%, Mn: 0.86%, Si: 0.15%, Mo: 0.29 %, Ni: 2.35%, S: 0.006%, P: 0.005%, the balance is Fe, and other unavoidable impurity elements.

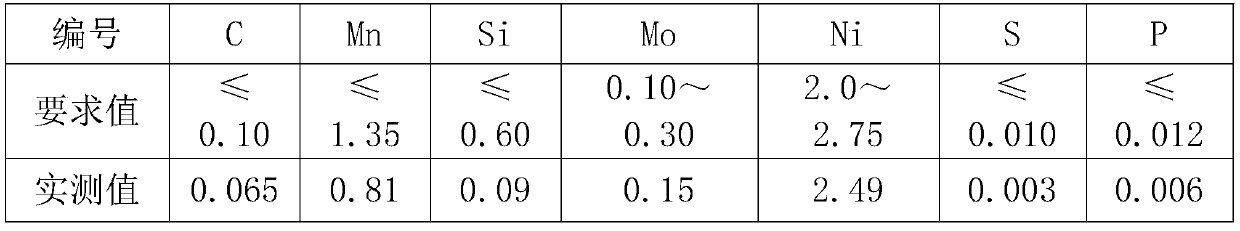

[0033] Table 1 Deposit metal chemical composition %

[0034] Numbering C mn Si Mo Ni S P Required value ≤0.10 ≤1.35 ≤0.60 0.10~0.30 2.0~2.75 ≤0.010 ≤0.012 measured value 0.067 0.86 0.15 0.29 2.35 0.006 0.005

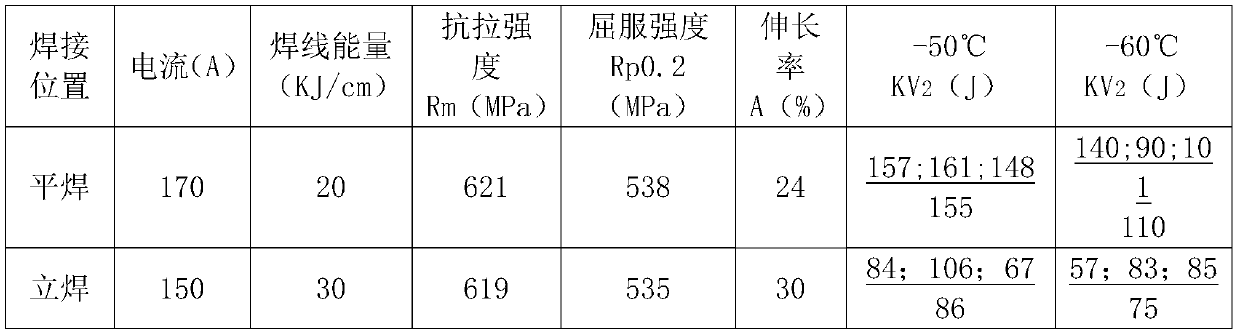

[0035] Table 2 Formulation 1 Deposited Metal Mechanical Properties (620℃×1h)

[0036]

[0037] Note: preheating and interlayer temperature: 100°C voltage 25V

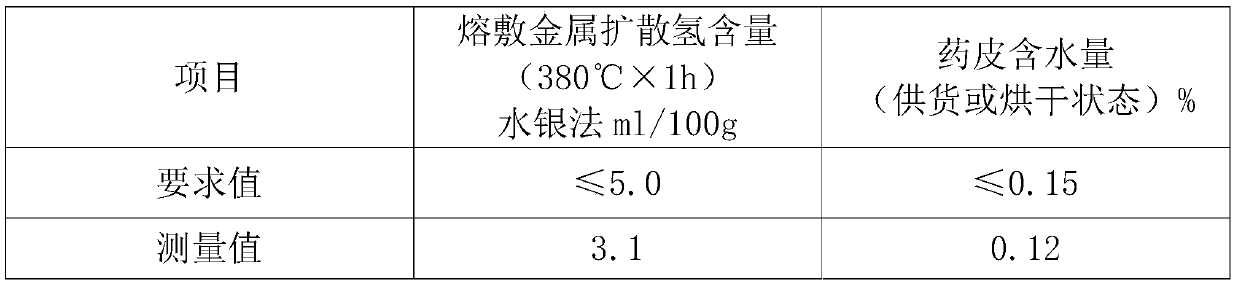

[0038] Table 3 Water content and diffusible hydrogen of drug skin

[0039]

[0040] In the above embodiment, more specifically, the diameter of the low alloy electrode is 1.5 mm.

[0041] In the above embodiments, more specifically, the welding core is...

Embodiment 2

[0046] A formula of low-alloy welding rod for 07MnNiMoDR steel-50℃ spherical tank, including welding core and coating, the mass percentage of its chemical composition is: C: 0.03-0.08%, Mn: 0.5-1.2%, Si: 0.1- 0.5%, Mo: 0.12-0.30%, Ni: 2.1-2.6%, S: 0.001-0.009%, P: 0.001-0.009%, the balance is Fe, and other unavoidable impurity elements.

[0047] Table 4 Formulation 2 Deposited Metal Chemical Composition %

[0048]

[0049] Table 5 Formula 2 Deposited Metal Mechanical Properties (620℃×1h)

[0050]

[0051] Note: Preheating and interlayer temperature: 100°C voltage 25V, X-ray flaw detection I

[0052] In the above embodiment, more specifically, the diameter of the low-alloy electrode is 2mm.

[0053] In the above embodiment, more specifically, the welding core is made of carbon steel.

[0054] In the above embodiment, more specifically, the thickness of the coating is 200% of the diameter of the welding core.

[0055] In the above embodiment, more specifically, the m...

Embodiment 3

[0058] A formula of low-alloy welding rod for 07MnNiMoDR steel-50℃ spherical tank, including welding core and welding rod, the mass percentage of its chemical composition is: C: 0.03-0.08%, Mn: 0.5-1.2%, Si: 0.1-0.5 %, Mo: 0.12-0.30%, Ni: 2.1-2.6%, S: 0.001-0.009%, P: 0.001-0.009%, the balance is Fe, and other unavoidable impurity elements.

[0059] Table 6 Chemical composition of deposited metal %

[0060]

[0061] Table 7 Mechanical Properties of Electrode Deposited Metal (620℃×1h)

[0062]

[0063] Note: preheating and interlayer temperature: 100°C voltage 25V

[0064] In the above embodiment, more specifically, the diameter of the low-alloy electrode is 2.5 mm.

[0065] In the above embodiments, more specifically, the welding core is made of alloy steel.

[0066] In the above embodiment, more specifically, the thickness of the coating is 100% of the diameter of the welding core.

[0067] In the above embodiment, more specifically, the mass of the coating is 25% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com