A high-strength wire rod with excellent low-temperature performance and its manufacturing method

A low-temperature performance and manufacturing method technology, which is applied in the field of high-strength wire rod and its manufacturing, can solve the problems of inability to guarantee engineering safety and reduced plasticity and toughness, and achieve the effect of improving safety reliability and low-temperature plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

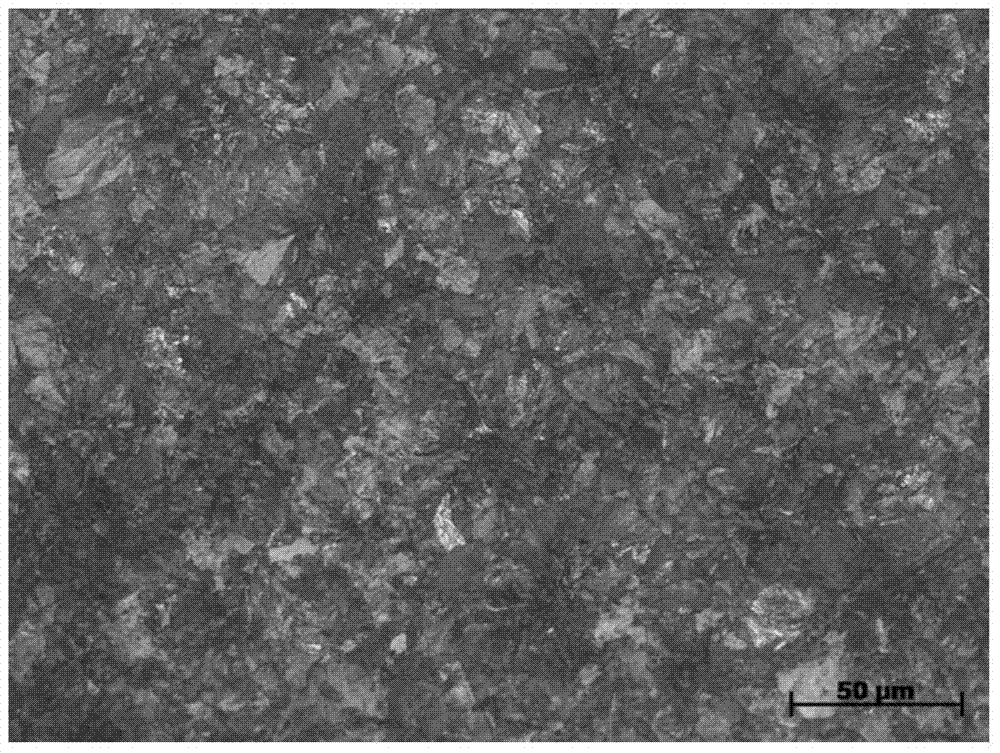

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with embodiment.

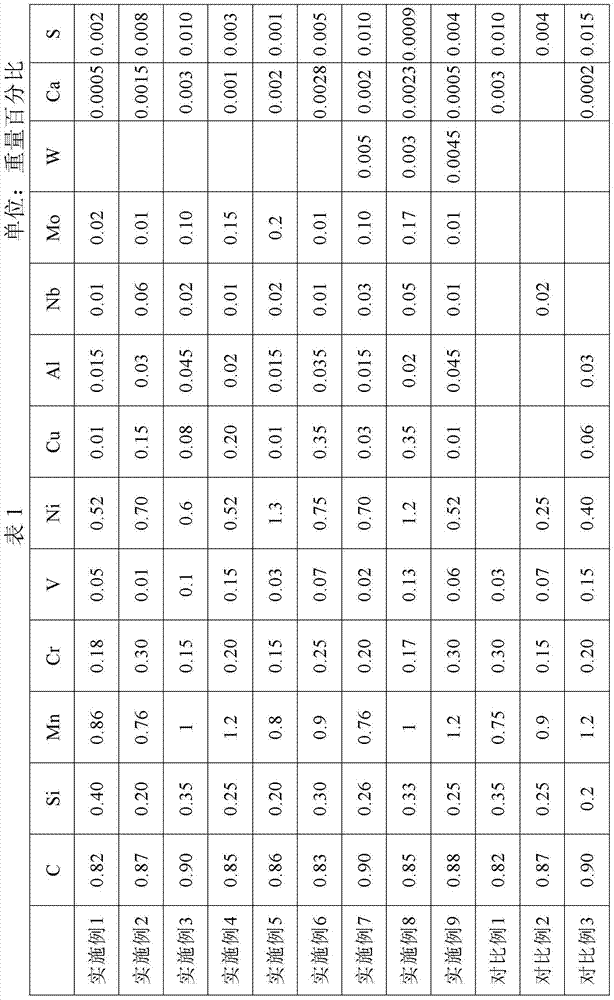

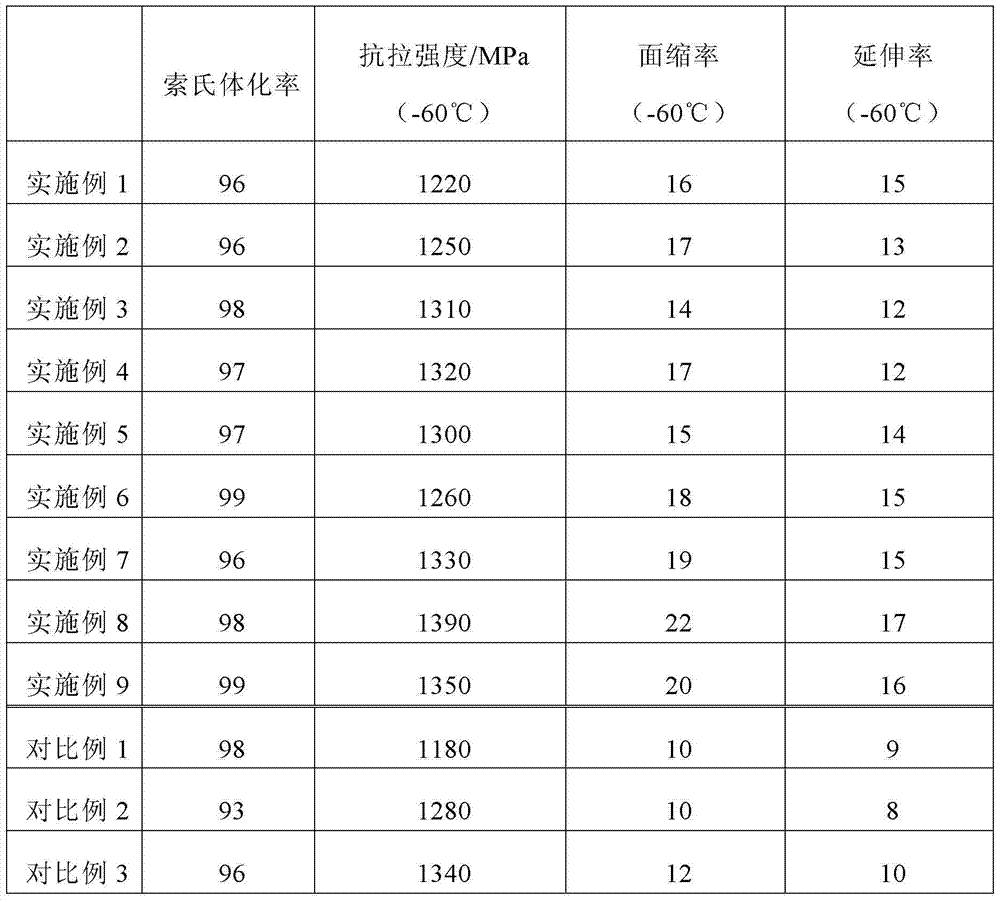

[0039] Table 1 shows the chemical compositions of the wire rods of Examples 1-9 of the present invention and comparative alloys.

[0040]

[0041] The manufacture method of the wire rod of embodiment 1-9 is as follows:

[0042] Embodiment 1, 2, 5, 7, 9 and comparative example 1 adopt electric furnace+LF+VD smelting, embodiment 3, 4, 6, 8 and comparative example 2, 3 adopt converter+LF+RH process to smelt, control steel The S element content is lower than 0.01%, while the O content in the steel is controlled to be lower than 20ppm, the N content is lower than 45ppm, and the H content is lower than 2ppm. Feed Si-Ca wire before tapping. VD or RH vacuum treatment times were 35 and 40 minutes, respectively. A billet continuous casting machine is used to cast the alloy into a bloom, and the section size of the billet is 250-500×250-500mm. The casting temperature of the tundish of Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com