Active let-off device and method of three-dimensional loom

A technology of active let-off and three-dimensional loom, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of increasing the friction damage of the winding device, the inability to meet the independent movement of the bobbin, and the active warp feeding, and the large number of warps. Achieve the effect of maintaining tension, simple structure and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. The operating methods not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

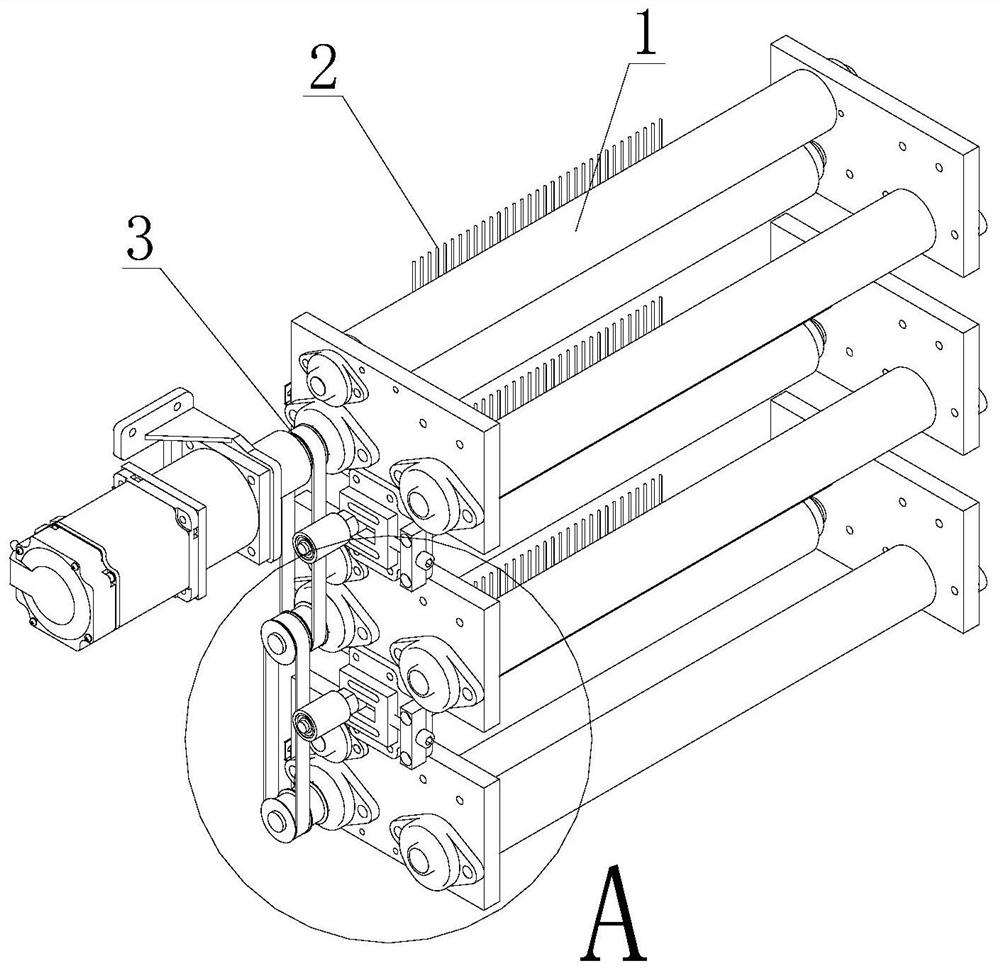

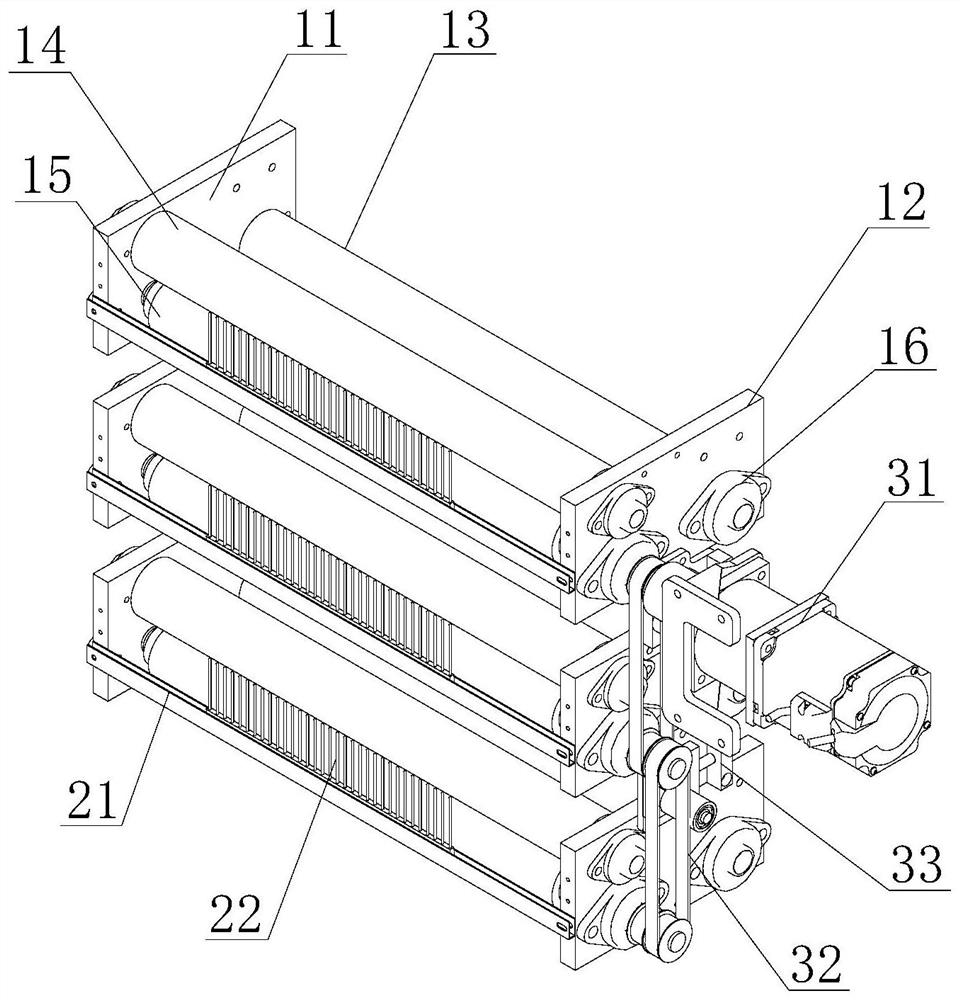

[0037] Such as figure 1 As shown, the active warp let-off device of the three-dimensional loom in this embodiment includes three roller turning devices 1 arranged at equal intervals longitudinally and parallel to each other, and a yarn dividing device is provided on the back of each roller turning device 1 2 Coordinating with it, the three roller turning devices 1 rely on the belt transmission device 3 arranged on its side for transmission.

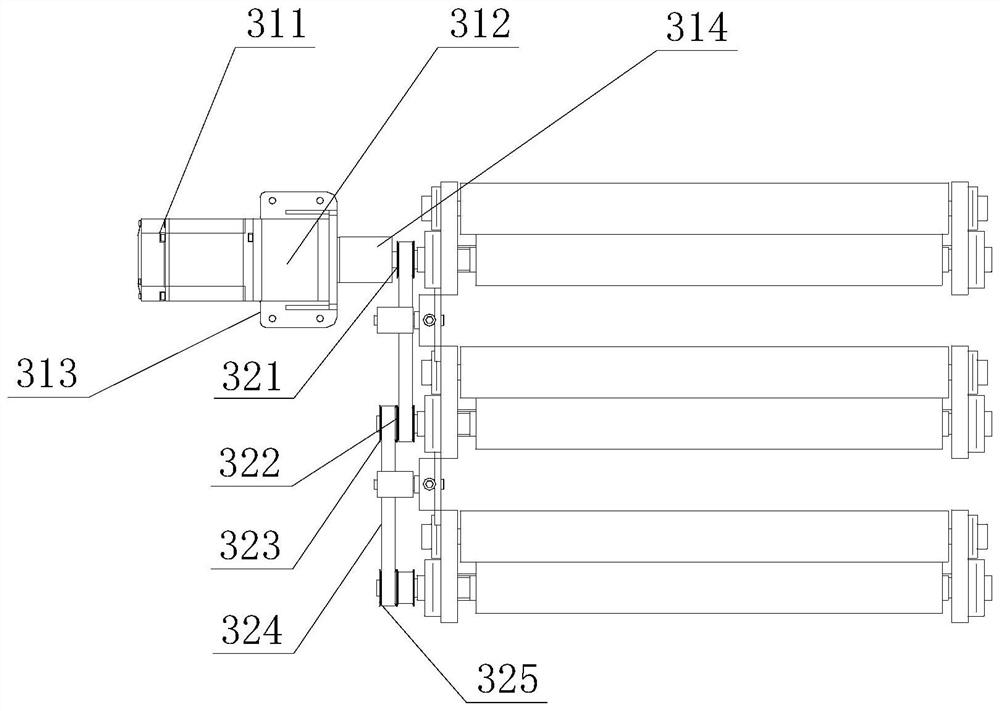

[0038] Such as figure 2 As shown, the yarn splitting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com