A kind of formaldehyde-free cotton fabric processing method with durable luster

A processing method and cotton fabric technology, applied in plant fiber, textiles, papermaking, fiber treatment, etc., can solve the problems of strong fabric damage, high formaldehyde content, and inability to obtain glossy patterns, etc., to avoid stiff hand feeling and simple process flow , Ease of industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Embodiment 2

(3) the fabric in the step (2) is first calendered by oil surface calender, and the pressure is at 8 kilograms, and 200 ℃ of temperature are calendered.

The speed of the locomotive is 40 m / min, and the calendering is performed for 3 times continuously; then the calendering is carried out by a mirror calender, the pressure is controlled at 8.5 kg, and the temperature is 150

℃, the speed of the calender is 60 m / min, and the calender is continuously calendered twice to obtain a cotton fabric with durable luster.

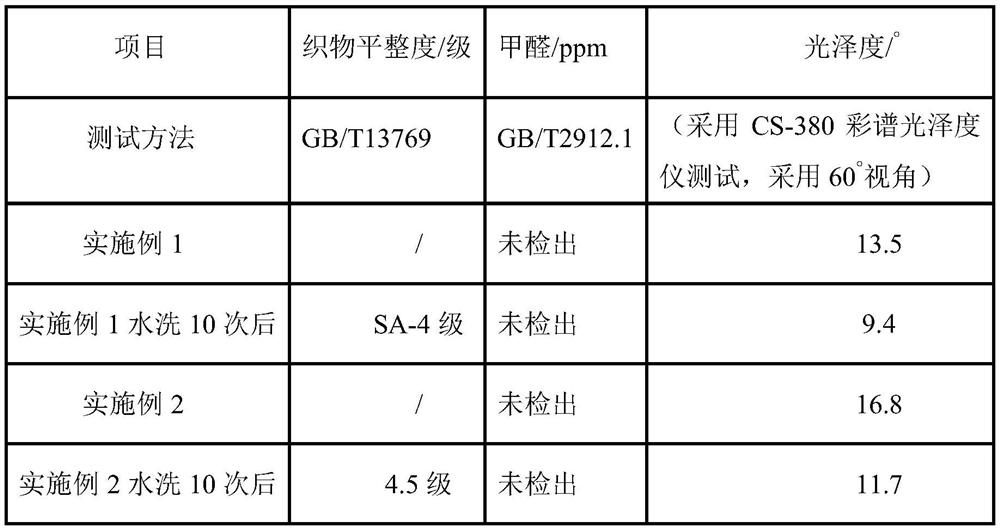

After embodiment 1 and embodiment 2 are implemented, data index is as shown in table 1.

Table 1

[0040]

[0041] Note: according to GB / T3921, wash with water after being naturally dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com