Acrylic resin, preparation method and application thereof

A technology of acrylic resin and formulation, applied in the direction of coating, etc., to achieve the effect of wide molecular weight distribution, high hardness and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

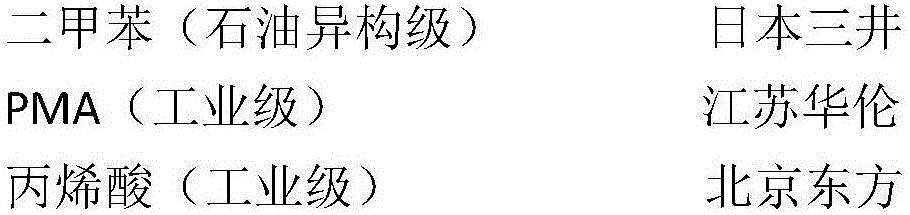

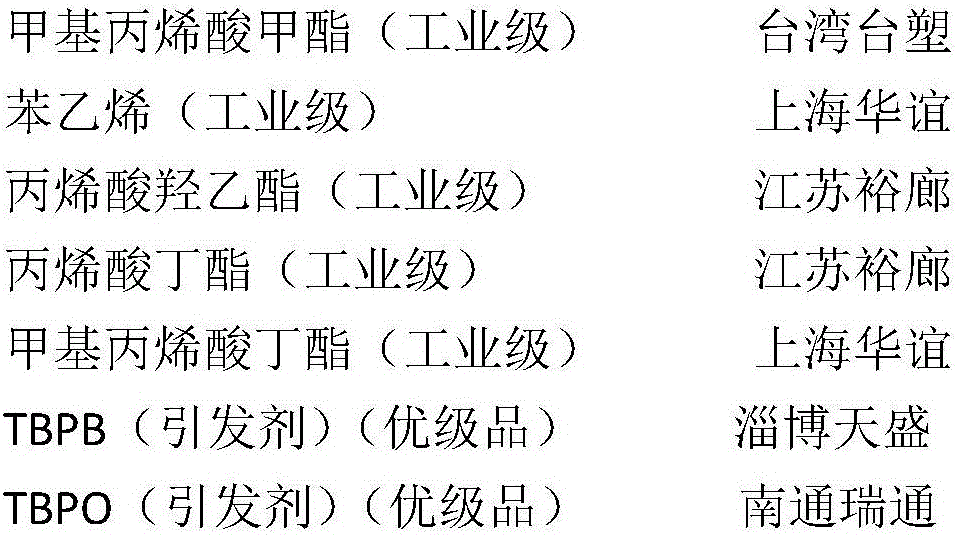

Method used

Image

Examples

Embodiment 1

[0038] The acrylic resin (HBU6230-60%) of this embodiment is made of component A, component B, component C, component D and E; among them,

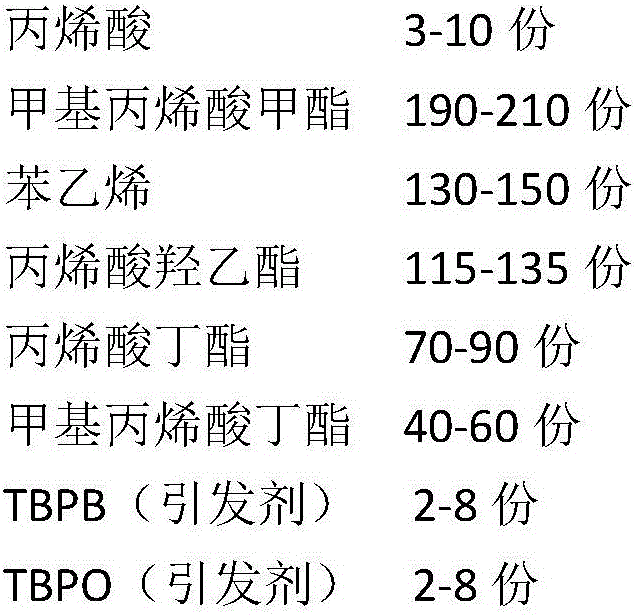

[0039] The A component includes the following parts by weight:

[0040] Xylene 300 parts

[0041] PMA 43 servings

[0042] The B component includes the following parts by weight:

[0043]

[0044] The C component includes the following parts by weight:

[0045] TBPB 0.5 copies

[0046] Xylene 5 parts

[0047] D component includes the following components by weight:

[0048] TBPB 0.5 copies

[0049] Xylene 5 parts

[0050] E: The following parts by weight:

[0051] 50 parts of xylene.

[0052] The preparation method of acrylic resin HBU6230-60% of this embodiment includes the following steps:

[0053] (1) Add the formula A component, stir and heat to reflux, keep the temperature at 138~144℃;

[0054] (2) Stir the formula amount of component B and add it to the system of step (1) in 4 drops, each time for 15-20 minutes, the first three drops of component B are...

Embodiment 2

[0058] The acrylic resin (HBU6230-60%) of this embodiment is made of component A, component B, component C, component D and E; among them,

[0059] The A component includes the following parts by weight:

[0060] Xylene 290 parts

[0061] PMA 33 copies

[0062] The B component includes the following parts by weight:

[0063]

[0064] The C component includes the following parts by weight:

[0065] TBPB (initiator) 0.1 part

[0066] Xylene 2 parts

[0067] D component includes the following components by weight:

[0068] TBPB (initiator) 0.1 part

[0069] Xylene 2 parts

[0070] E includes the following parts by weight:

[0071] 40 parts of xylene.

[0072] The preparation method of acrylic resin HBU6230-60% of this embodiment includes the following steps:

[0073] (1) Add the formula A component, stir and heat to reflux, keep the temperature at 138~144℃;

[0074] (2) Stir the formula amount of component B and add it to the system of step (1) 3 times, each time for 15-20 minutes, the first two dro...

Embodiment 3

[0078] The acrylic resin (HBU6230-60%) of this embodiment is made of component A, component B, component C, component D and E; among them,

[0079] The A component includes the following parts by weight:

[0080] 310 parts of xylene

[0081] PMA 53 copies

[0082] The B component includes the following parts by weight:

[0083]

[0084] The C component includes the following parts by weight:

[0085] TBPB (initiator) 2 parts

[0086] Xylene 10 parts

[0087] D component includes the following components by weight:

[0088] TBPB (initiator) 2 parts

[0089] Xylene 10 parts

[0090] E includes the following parts by weight:

[0091] 60 parts of xylene.

[0092] The preparation method of acrylic resin HBU6230-60% of this embodiment includes the following steps:

[0093] (1) Add the formula A component, stir and heat to reflux, keep the temperature at 138~144℃;

[0094] (2) Stir the formula amount of B component evenly and add it to the system of step (1) in 5 drops, each time for 15-20min, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com