Processing method of formaldehyde-free cotton fabric with durable gloss

A processing method and technology for cotton fabrics, applied in the directions of plant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of inability to obtain glossy patterns, great damage to fabric strength, single glossy fabrics, etc., and achieve easy industrial implementation, smooth appearance, The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

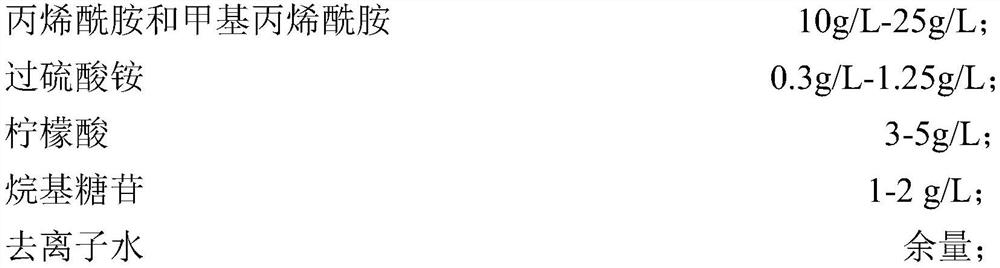

[0031] (1) After the cotton fabric is singed-desizing-dyed (or printed), the cotton fabric is grafted with a mixture of acrylamide and methacrylamide. The specific grafting process is: acrylamide and methacrylamide The mass ratio is 2:3, acrylamide and methacrylamide 10g / L, citric acid 5g / L, alkyl glycoside APG10 dosage 1g / L, ammonium persulfate, 0.8g / L, and the balance is deionized water. The bath ratio is 1:20, and the temperature is raised to 70°C at a rate of 1°C / min for 70 minutes. After the grafting reaction is completed, use 1g / L Pingping to add O, the bath ratio is 1:20, and wash with water at 85°C for 10min. Then wash with cold water for 10 minutes.

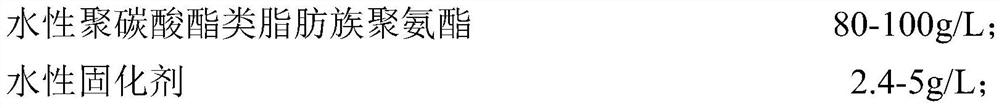

[0032] (2) Fabric padding water-based polyurethane finishing liquid in step (1), the formula of finishing liquid is: water-based polycarbonate class aliphatic polyurethane RU-13-442 (the product trade name of Stahl company) consumption 100g / L, Bayhydur The dosage of XP 2655 is 4% of that of RU-13-442, the dosage of car...

Embodiment 2

[0035] (1) After the cotton fabric is singed-desizing-dyed (or printed), the cotton fabric is grafted with a mixture of acrylamide and methacrylamide. The specific grafting process is: acrylamide and methacrylamide The mass ratio of acrylamide and methacrylamide is 3:2, 25g / L of acrylamide and methacrylamide, 3g / L of citric acid, 1g / L of alkyl glycoside APG10, 1.25g / L of ammonium persulfate, and the balance is deionized water. The bath ratio is 1:20, and the temperature is raised to 75°C at a rate of 1°C / min for 50 minutes. After the grafting reaction is completed, use 0.5g / L Pingping to add O, the bath ratio is 1:20, and wash with water at 80°C for 10-15min. Then wash with cold water for 15 minutes.

[0036] (2) fabric padding water-based polyurethane finishing liquid in step (1), the formula of finishing liquid is: water-based polycarbonate class aliphatic polyurethane RU-13-442 (the product trade name of Stahl company) consumption 80g / L, Bayhydur The dosage of XP 2655 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com