Pulping device and system and pulping method

A slurry and cylinder technology, applied in the field of papermaking, can solve the problems of inability to retain axial length fibers, high micronano cellulose materials, and inability to retain fiber shapes, so as to improve fiber stripping and picking efficiency, reduce vortex, and realize Effects of Continuity and Industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

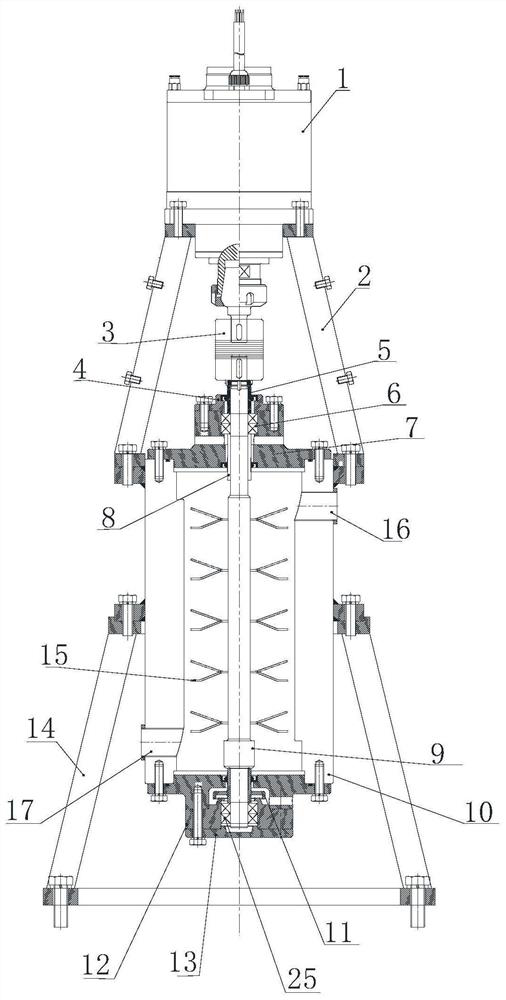

[0038] Such as figure 1 As shown, a beating device includes a motor 1 , a motor bracket 2 , a rotating shaft 9 , a cylinder 10 , a cylinder bracket 14 and a blade 15 . The motor is fixed on the motor bracket, and the output shaft of the motor is connected with the rotating shaft through a coupling 3 . The motor is a high-speed motor capable of continuous and stable operation at high speed, with a speed of more than 8000 rpm. The motor drives the rotating shaft to rotate, and the torque of the rotating shaft reaches above 1.0N·M.

[0039] The cylinder body is made of stainless steel plate with a wall thickness of 2.5mm or more. In order to avoid large heat generated during high-speed rotation and to reduce noise, a jacket is installed outside the cylinder wall, and circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com